Table of Contents

ToggleLiquid Silicone Rubber (LSR) has become a preferred material for medical devices, wearable electronics, automotive components, sealing systems, and consumer products due to its excellent biocompatibility, flexibility, durability, and chemical resistance.

However, many OEMs and product developers face a major challenge:

How to successfully transform an LSR product design into stable, cost-effective mass production.

This is where a professional LSR injection molding manufacturing partner plays a critical role. A qualified partner does more than simply produce parts — they help optimize design, reduce tooling risk, validate processes, and scale production reliably.

This article explains why choosing the right manufacturing partner is essential to bring your LSR design into mass production, and how an experienced LSR factory supports each stage from concept to volume manufacturing.

1. Why LSR Designs Often Fail to Reach Mass Production

Many LSR projects stall between design and mass production due to:

- Design not optimized for LSR injection molding

- Mold structure too complex or costly

- Unstable molding process

- High scrap rate during pilot production

- Inconsistent quality in scale-up phase

- Lack of engineering support from suppliers

Without the right manufacturing partner, companies often experience long development cycles, rising tooling costs, and delayed market entry.

2. What Makes a Good Manufacturing Partner for LSR Projects

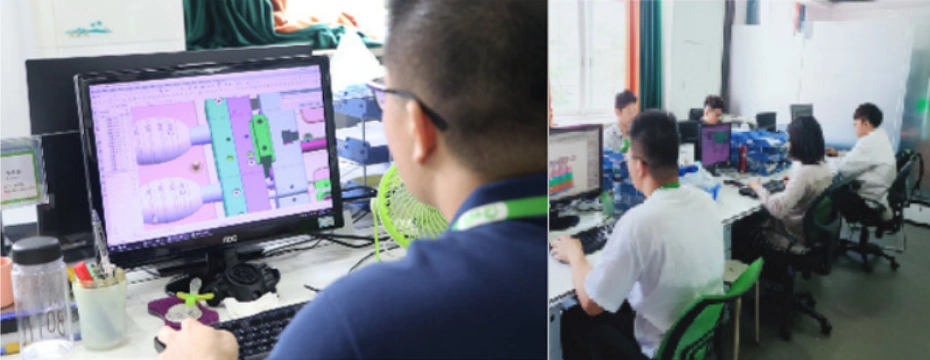

2.1 Strong LSR Engineering Capability

A professional LSR manufacturing partner should provide:

- DFM (Design for Manufacturability) analysis

- Mold flow and venting optimization

- Gate location and parting line optimization

- Material selection support (medical, food-grade, industrial LSR)

This ensures your LSR design is truly manufacturable at scale.

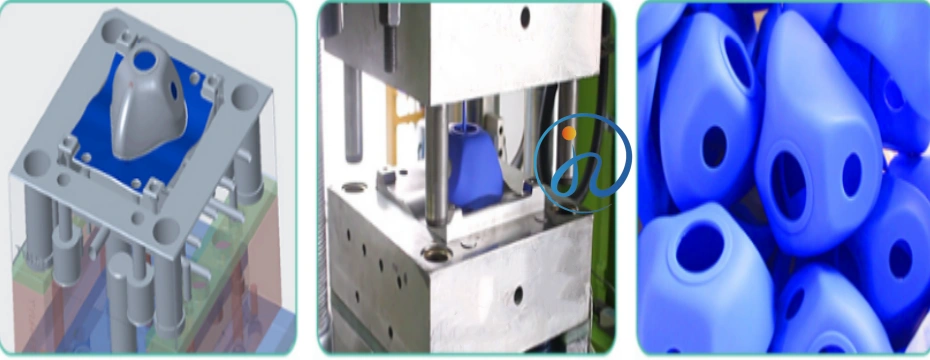

2.2 In-House Mold Design and Tooling

Manufacturers with in-house tooling capabilities offer:

- Faster design iteration

- Better control of mold quality

- Reduced communication cost

- Shorter lead time from design to sampling

This is essential for moving quickly from prototype to mass production.

3. From LSR Design to Prototype: The First Step Toward Mass Production

3.1 Rapid Prototyping for LSR Products

A qualified manufacturing partner supports:

- Prototype mold development

- Small-batch LSR injection molding

- Functional testing and verification

- Design optimization based on real molding feedback

Early prototype validation reduces the risk of costly tooling rework later.

3.2 DFM Feedback to Improve Production Readiness

Key areas improved through DFM:

- Wall thickness uniformity

- Draft angles for demolding

- Elimination of undercuts

- Improved sealing and flash control

This makes your LSR design ready for scalable manufacturing.

4. Tooling Strategy: Building the Foundation for Mass Production

4.1 Scalable Mold Design

A professional LSR manufacturing partner designs molds with scalability in mind:

- Start with low-cavity molds

- Modular inserts for future cavity expansion

- Cold runner or hot runner system optimized for yield

- High-precision temperature control

This allows smooth transition from pilot runs to high-volume production.

4.2 Tooling Quality Impacts Long-Term Cost

High-quality molds reduce:

- Flash

- Scrap rate

- Mold maintenance cost

- Downtime

Although initial tooling cost may be higher, long-term manufacturing cost is significantly lower.

5. Process Validation: Turning Design into Stable Production

5.1 Process Development & Parameter Optimization

A reliable manufacturing partner develops stable LSR injection parameters:

- Injection pressure

- Cure time

- Mold temperature

- Material mixing ratio

This ensures consistency when moving from prototype to mass production.

5.2 Quality Control System

Key quality control measures include:

- In-process inspection

- Dimensional measurement

- Functional testing

- Batch traceability

Stable quality systems enable smooth scale-up without quality risks.

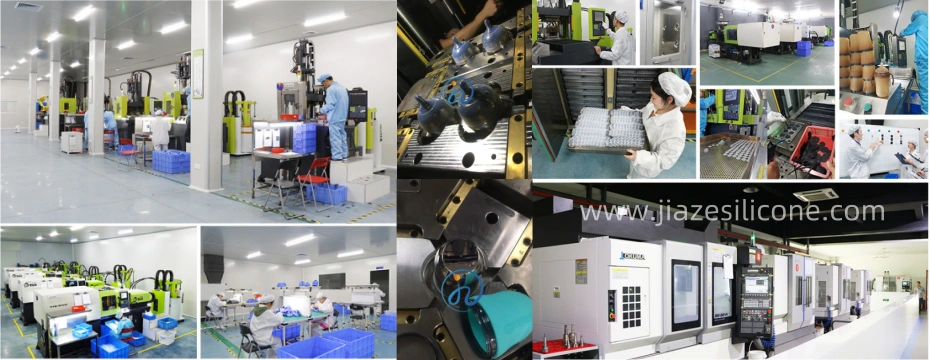

6. Scaling from Pilot Production to Mass Manufacturing

6.1 Production Capacity Planning

A capable LSR partner supports:

- Capacity evaluation

- Multi-shift production planning

- Automation integration

- Equipment scalability

This ensures your production volume grows with market demand.

6.2 Automation for High-Volume LSR Production

Automation helps achieve:

- Stable part consistency

- Lower labor cost

- Reduced contamination risk (especially for medical LSR)

- Higher production efficiency

This is essential for mass production success.

7. Cost Optimization Through Manufacturing Partnership

A long-term manufacturing partner helps optimize:

- Material utilization

- Runner waste reduction

- Cycle time improvement

- Yield rate improvement

- Tool maintenance planning

This directly lowers unit cost as production volume increases.

8. Industries That Benefit from LSR Mass Production Partnership

LSR injection molding is widely used in:

- Medical devices (respiratory masks, seals, valves)

- Wearable electronics (gaskets, waterproof components)

- Automotive (connectors, seals, vibration dampers)

- Consumer products (baby care, kitchenware)

- Industrial sealing solutions

In all these industries, a stable manufacturing partner determines whether an LSR design can be commercialized successfully.

9. How to Evaluate the Right LSR Manufacturing Partner

When choosing a partner to bring your LSR design into mass production, evaluate:

- LSR injection molding experience

- In-house mold making capability

- Medical or industrial certification experience

- Engineering support team

- Production scalability

- Quality management system

The right partner is not just a supplier, but an extension of your engineering and manufacturing team.

10. Long-Term Partnership: Beyond Just Production

The best LSR manufacturing partners provide:

- Continuous process improvement

- Design iteration support

- Cost-down engineering

- New material recommendations

- Ongoing tooling optimization

This long-term collaboration turns your LSR product into a sustainable, scalable business.

Conclusion

Transforming an LSR design into stable mass production is not only a manufacturing challenge — it is a systematic engineering and partnership process. By working with an experienced LSR injection molding manufacturing partner, OEMs can reduce development risk, shorten time-to-market, and achieve consistent, cost-effective mass production.

A professional manufacturing partner bridges the gap between LSR design concept and high-volume production reality, ensuring your product succeeds in competitive global markets.