Table of Contents

ToggleThe global need for high-quality half face mask respirators has surged due to industrial safety, healthcare emergencies, and heightened environmental awareness. While various materials can be used to make these masks—such as TPE, PVC, and traditional rubber—Liquid Silicone Rubber (LSR) stands out as the top choice for premium designs.

In this guide, we explore the compelling reasons why LSR is preferred for manufacturing half-face respirators, focusing on material performance, comfort, hygiene, durability, and manufacturability.

1. What Is a Half Face Mask Respirator?

A half face mask respirator is a reusable mask that covers the nose, mouth, and chin, forming a tight seal to protect the wearer from harmful particulates, gases, or pathogens. Unlike disposable masks, they are typically equipped with replaceable filters and are used in:

- Medical settings

- Construction and manufacturing

- Laboratories and research

- Firefighting and emergency services

To ensure protection, the mask must achieve an airtight seal while remaining comfortable for long periods—this is where LSR becomes crucial.

2. What Is Liquid Silicone Rubber (LSR)?

LSR (Liquid Silicone Rubber) is a two-component, platinum-cured elastomer that is processed using injection molding. It is known for its:

- Excellent flexibility and softness

- Heat and chemical resistance

- Biocompatibility and hypoallergenic properties

- Long-term durability

LSR is widely used in applications where human contact, hygiene, and precision are required—making it ideal for respiratory devices.

3. Key Benefits of LSR for Half Face Mask Respirators

Let’s dive into the specific reasons LSR is the best choice for manufacturing half face mask respirator components:

3.1 Biocompatibility & Safety

LSR is:

- Non-toxic and hypoallergenic

- Compliant with FDA 21 CFR 177.2600, ISO 10993, and USP Class VI

- Free from BPA, phthalates, and latex

This ensures the mask won’t cause irritation or allergic reactions—even during extended wear, making it suitable for healthcare and industrial workers alike.

3.2 Superior Seal Performance

Achieving a leak-proof seal is the core function of a respirator. LSR offers:

- High elasticity to conform to facial contours

- Stable sealing performance over long use

- Ability to maintain flexibility in extreme temperatures

Even during physical movement, the LSR seal ensures consistent protection.

3.3 Exceptional Comfort

Comfort drives compliance. If a mask is uncomfortable, users won’t wear it properly.

LSR contributes by:

- Providing a soft-touch skin interface

- Remaining flexible at both high and low temperatures

- Being ultra-lightweight compared to rubber alternatives

This results in reduced skin pressure and friction, critical for long-term use in hospitals or factories.

3.4 Durability and Long Product Life

Half face respirators must endure repeated cleaning and disinfection. LSR is:

- Resistant to alcohol, detergents, and UV radiation

- Unaffected by autoclaving or high-temperature sterilization

- Capable of lasting hundreds of use cycles without degradation

This improves ROI for manufacturers and end-users alike.

3.5 Transparent and Colorable

LSR is naturally translucent, allowing visibility of internal mask structures if needed. It is also:

- Easily pigmented without affecting performance

- Ideal for brand customization or color-coded safety masks

This supports both functional and aesthetic design flexibility.

4. LSR vs. Other Materials for Respirators

Here’s how LSR compares with common materials used for half face mask respirators:

| Property | LSR | TPE | PVC | Rubber |

|---|---|---|---|---|

| Biocompatibility | Excellent | Moderate | Poor | Moderate |

| Heat Resistance | Up to 250°C | ~100°C | ~70°C | ~120°C |

| Softness/Comfort | Very soft | Moderate | Stiff | Stiff |

| Reusability | High | Low | Very low | Moderate |

| Mold Complexity | High compatibility | Limited | Limited | Moderate |

As seen above, LSR outperforms its competitors in almost every critical area.

5. Manufacturing Half Face Masks with LSR

Custom manufacturing of half face respirators using LSR involves:

5.1 Design Engineering

- 3D CAD modeling based on ergonomic studies

- Integration of sealing zones, filter ports, and straps

- Finite element analysis (FEA) for seal performance

5.2 Mold Tooling

- Precision steel molds designed for LSR flow characteristics

- Cold-runner systems for minimal waste

- Multi-cavity options for scalability

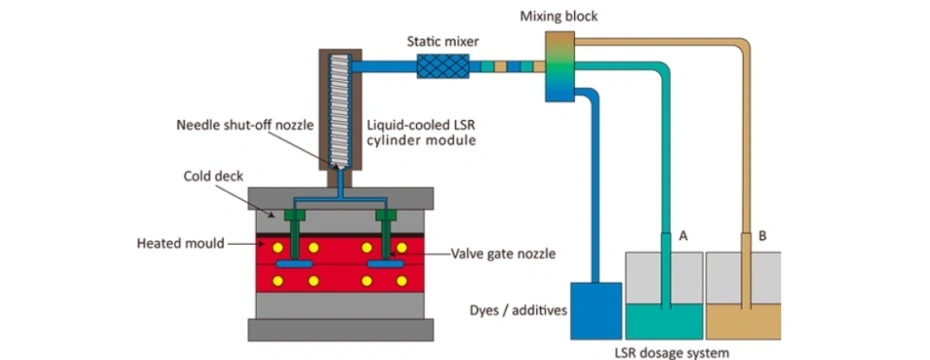

5.3 LSR Injection Molding Process

- Metering and mixing of A & B components

- Injection into heated mold

- Rapid curing and automatic demolding

- Minimal flash, no need for post-processing

5.4 Cleanroom Production

Medical-grade half face respirators are often produced in ISO Class 7 or 8 cleanrooms, ensuring sterility and compliance with healthcare standards.

6. Applications of LSR Half Face Mask Respirators

LSR respirators are used in:

- Hospitals and clinics: Surgeons, nurses, caregivers

- Pharmaceutical & lab environments

- Industrial and chemical processing plants

- Disaster response teams and firefighters

- Military or tactical operations

Custom LSR formulations can even support anti-microbial or anti-static properties for specialized applications.

7. Environmental and Regulatory Advantages

Using LSR in half face respirators supports:

- Sustainable design: Reusable and recyclable

- Compliance with international standards (CE, FDA, ISO, NIOSH)

- Minimal VOC emissions during production

- Safe disposal and non-toxic degradation

For companies focused on ESG goals, LSR offers a compelling, eco-friendly solution.

8. Case Studies: LSR Respirator Success Stories

Medical:

A leading European mask manufacturer replaced TPE with LSR for surgical masks, reporting a 35% improvement in seal quality and 50% reduction in returns due to allergic reactions.

Industrial:

An American chemical plant adopted LSR respirators for their staff, noting higher employee satisfaction and longer product lifespan despite daily sterilization.

Conclusion: Choose LSR for Performance, Safety, and Comfort

For companies looking to develop high-performance, user-friendly, and compliant half face mask respirators, LSR (Liquid Silicone Rubber) is the best-in-class material. It meets the highest standards for:

- Human safety

- Long-term durability

- Sealing performance

- Modern, customizable design

- Cost-effective manufacturing