Table of Contents

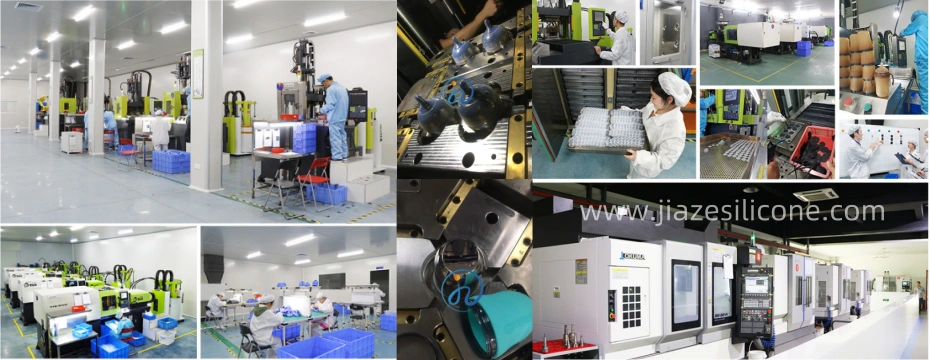

ToggleIn today’s highly competitive manufacturing environment, Liquid Silicone Rubber (LSR) injection molding has become a preferred solution for producing high-performance, medical-grade, and precision silicone components. However, many design engineers face challenges when translating innovative product ideas into manufacturable, cost-effective, and scalable LSR parts. This is where an experienced LSR injection manufacturer plays a critical role.

From early-stage design validation to tooling, prototyping, material selection, and mass production, the right manufacturing partner can significantly reduce risks, shorten development cycles, and improve final product quality.

1. Understanding the Role of an LSR Injection Manufacturer

An LSR injection manufacturer is not just a parts supplier. In modern product development, they function as a technical partner who supports design engineers in:

- Design for Manufacturability (DFM)

- Material engineering and formulation

- Tooling and mold design

- Prototyping and validation

- Process development and optimization

- Quality control and regulatory compliance

- Scaling from prototype to mass production

By leveraging real-world manufacturing expertise, design engineers can avoid common pitfalls such as poor mold design, excessive parting lines, flash issues, air traps, and inconsistent curing.

2. Early Design Support: Design for Manufacturability (DFM)

2.1 Identifying Potential Design Risks

LSR behaves differently from thermoplastics. It is a low-viscosity, thermoset material that requires special gating, venting, and mold temperature control. An experienced LSR injection manufacturer helps design engineers:

- Optimize wall thickness

- Avoid undercuts that increase tooling cost

- Minimize parting line visibility

- Design proper sealing features

- Prevent air entrapment and short shots

Early DFM analysis ensures that the product design aligns with real production capabilities.

2.2 Optimizing Part Geometry for LSR Injection

Manufacturers provide feedback on:

- Draft angles suitable for demolding

- Ribs and reinforcement design

- Overmolding feasibility (LSR over plastic or metal)

- Gate location for uniform flow

- Tolerance feasibility based on LSR shrinkage behavior

This collaboration improves yield rate and reduces mold rework.

3. Material Selection Guidance for LSR Components

3.1 Matching LSR Grades to Application Needs

Different applications require different LSR formulations. A professional LSR injection manufacturer assists design engineers in choosing the right grade based on:

- Medical vs. food-grade requirements

- Transparency and optical clarity

- Tear strength and elongation

- Compression set and sealing performance

- Temperature resistance

- Chemical and UV resistance

For example, medical devices require platinum-cured medical-grade LSR that meets ISO 10993 or USP Class VI standards, while industrial seals may prioritize durability and oil resistance.

3.2 Custom Compounding and Color Matching

Manufacturers can support:

- Custom color matching

- Additives for flame retardancy

- Antimicrobial or biocompatible formulations

- High-purity LSR for healthcare applications

This level of material engineering helps design engineers meet both functional and regulatory goals.

4. Prototyping Support: From Concept to Validation

4.1 Rapid Prototyping with LSR

Before investing in expensive production tooling, LSR injection manufacturers can provide:

- Soft tooling for pilot runs

- Rapid prototyping molds

- Low-volume injection molding

- Prototype validation samples

This allows design engineers to test:

- Fit and assembly

- Ergonomics and sealing performance

- Mechanical properties

- Surface texture and appearance

4.2 Design Iteration Based on Real Testing

Prototypes often reveal design issues not visible in CAD models. Manufacturers support iterative design improvements by:

- Adjusting wall thickness

- Modifying sealing lips

- Refining snap-fit features

- Improving mold flow performance

This feedback loop reduces the risk of costly tooling changes later.

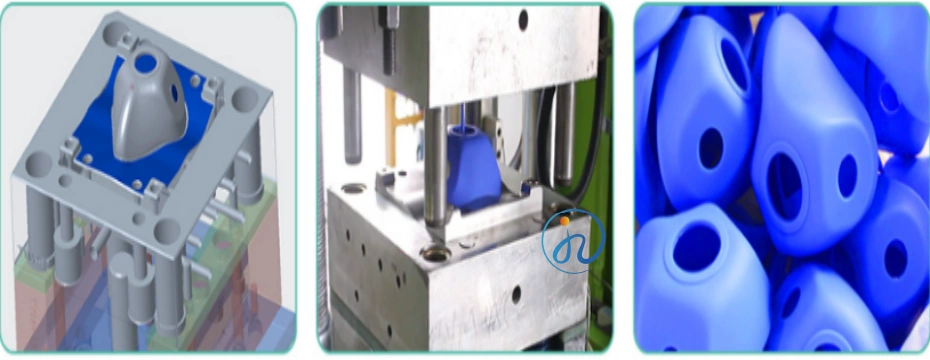

5. Tooling and Mold Design Expertise

5.1 Precision Mold Engineering for LSR Injection

LSR molds are more complex than standard plastic injection molds. An experienced LSR injection manufacturer provides:

- Cold runner system design

- Proper venting structures

- Vacuum-assisted molding solutions

- Multi-cavity mold optimization

- Automation-ready mold design

Design engineers benefit from manufacturer input on:

- Mold parting strategy

- Insert molding and overmolding feasibility

- Ejection system design for soft elastomers

5.2 Cost Optimization in Tooling Design

Tooling cost is a major investment. Manufacturers help optimize tooling by:

- Simplifying mold structure

- Designing modular inserts for future revisions

- Optimizing cavity layout for volume scalability

- Balancing initial tooling cost vs. long-term production efficiency

This approach supports long-term product lifecycle planning.

6. Process Development and Parameter Optimization

6.1 Establishing Stable LSR Injection Parameters

LSR injection molding requires precise control of:

- Injection speed

- Mixing ratio

- Mold temperature

- Curing time

- Demolding conditions

Manufacturers assist design engineers by:

- Developing stable processing windows

- Validating part consistency

- Reducing cycle time

- Minimizing flash and defects

6.2 Supporting Complex Processes: Overmolding & Insert Molding

LSR is commonly used in:

- LSR overmolding on PC, ABS, or PBT

- Insert molding with metal components

- Multi-shot injection molding

Manufacturers guide design engineers on:

- Substrate material compatibility

- Surface treatment and adhesion promoters

- Mold alignment and fixture design

This ensures strong bonding and reliable performance.

7. Quality Assurance and Regulatory Compliance

7.1 Process Validation and Documentation

For medical, healthcare, and industrial applications, LSR injection manufacturers provide:

- IQ/OQ/PQ validation support

- Process capability studies (CPK)

- Material traceability

- Batch records and documentation

Design engineers benefit from a compliant manufacturing process that meets regulatory standards.

7.2 Inspection and Quality Control

Manufacturers implement:

- Dimensional inspection

- Visual defect detection

- Mechanical property testing

- Functional performance tests

This ensures design intent is consistently achieved in mass production.

8. Scaling from Prototype to Mass Production

8.1 Production Scalability Planning

LSR injection manufacturers help design engineers plan for:

- Volume ramp-up

- Multi-cavity mold upgrades

- Automation integration

- In-line quality inspection

- Cost-per-part optimization

Early scalability planning avoids redesigns when production volume increases.

8.2 Supply Chain and Manufacturing Reliability

Reliable manufacturers offer:

- Stable material sourcing

- Backup tooling strategies

- Long-term production support

- Lead time optimization

This ensures the product design remains commercially viable in the long term.

9. Cost Reduction Strategies with Manufacturer Collaboration

Working closely with an LSR injection manufacturer enables design engineers to:

- Reduce material waste

- Optimize part geometry for lower material usage

- Simplify assembly through integrated design

- Improve yield rate

- Lower tooling maintenance costs

Cost engineering becomes part of the design process, not an afterthought.

10. Why Early Collaboration with an LSR Injection Manufacturer Matters

Design engineers who involve manufacturers early benefit from:

- Fewer design revisions

- Faster time-to-market

- Lower tooling risks

- Better product performance

- Higher production consistency

Early collaboration transforms the manufacturer into a co-development partner, not just a supplier.

11. Choosing the Right LSR Injection Manufacturer for Design Support

When selecting an LSR injection manufacturing partner, design engineers should evaluate:

- Technical expertise in LSR injection molding

- Experience in medical or industrial applications

- In-house tooling and mold design capability

- Prototyping and low-volume production support

- Quality system certifications (ISO 13485, ISO 9001, etc.)

- Engineering communication and project management ability

A manufacturer with strong engineering support significantly improves project success rates.

Conclusion: LSR Injection Manufacturers as Strategic Partners for Design Engineers

An LSR injection manufacturer plays a crucial role in helping design engineers transform innovative concepts into reliable, manufacturable, and scalable silicone products. From DFM optimization and material selection to tooling, prototyping, quality assurance, and mass production, the right partner adds technical value at every stage of the product lifecycle.

By collaborating early and strategically with an experienced LSR injection manufacturer, design engineers can reduce development risks, control costs, improve performance, and accelerate time to market — ultimately delivering better products to end users.