Table of Contents

ToggleLiquid Silicone Rubber (LSR) has become one of the most preferred materials for modern product design, especially in medical devices, wearable electronics, automotive seals, consumer products, and infant care items. However, designing a part in LSR is very different from designing for traditional thermoplastics.

This is where an experienced LSR silicone molding partner plays a critical role. A professional manufacturer does not only provide production capacity, but also offers engineering support, design optimization, material expertise, tooling development, process validation, and scalable manufacturing solutions.

For product designers, choosing the right LSR molding partner can mean the difference between:

- A smooth transition from concept to mass production

- Or costly redesigns, delayed timelines, and quality risks

This article explains in detail how an LSR silicone molding partner helps product designers at every stage of product development, and why early collaboration leads to better performance, lower cost, and faster time-to-market.

What Is an LSR Silicone Molding Partner?

An LSR silicone molding partner is a specialized manufacturer that provides end-to-end services for Liquid Silicone Rubber injection molding, including:

- Design for Manufacturing (DFM) support

- LSR material selection guidance

- Tooling and mold development

- Prototyping and pilot runs

- LSR injection molding production

- Quality control and regulatory compliance

- Secondary operations such as overmolding and assembly

Unlike ordinary molders, professional LSR partners understand the unique behavior of liquid silicone rubber, including flow characteristics, curing kinetics, mold venting design, and automation requirements.

How LSR Silicone Molding Partner Supports Product Designers

1. Early-Stage Design Consultation (DFM & DFA Support)

Product designers often focus on function, aesthetics, and user experience. However, LSR molding introduces specific manufacturing constraints such as:

- Parting line control

- Flash management

- Undercut feasibility

- Wall thickness consistency

- Gate location optimization

An experienced LSR silicone molding partner provides Design for Manufacturing (DFM) and Design for Assembly (DFA) feedback early in the design phase. This prevents:

- Overly complex geometries

- Unmoldable features

- High tooling risk

- Unstable part quality

Early engineering involvement ensures that the design is optimized not only for performance but also for efficient and repeatable mass production.

2. Material Selection Guidance for LSR Applications

LSR materials vary widely in:

- Shore hardness

- Tensile strength

- Tear resistance

- Transparency

- Chemical resistance

- Biocompatibility

- Heat resistance

A professional LSR silicone molding partner helps product designers select the right grade of LSR material based on application requirements:

- Medical-grade LSR for healthcare devices

- Food-grade LSR for kitchenware and baby products

- Optical-grade LSR for lenses and light guides

- Flame-retardant LSR for electronics

This technical guidance ensures the final product meets functional, regulatory, and durability expectations.

3. Rapid Prototyping and Validation

Before mass production, product designers must validate:

- Fit and function

- Ergonomics

- Sealing performance

- Assembly compatibility

An LSR molding partner can offer:

- Rapid tooling solutions

- Soft tooling for prototyping

- Low-volume pilot production

This allows designers to physically test real LSR parts, instead of relying only on CAD models or 3D printed substitutes that cannot fully simulate silicone performance.

Prototyping with real LSR material reduces development risks and shortens the design iteration cycle.

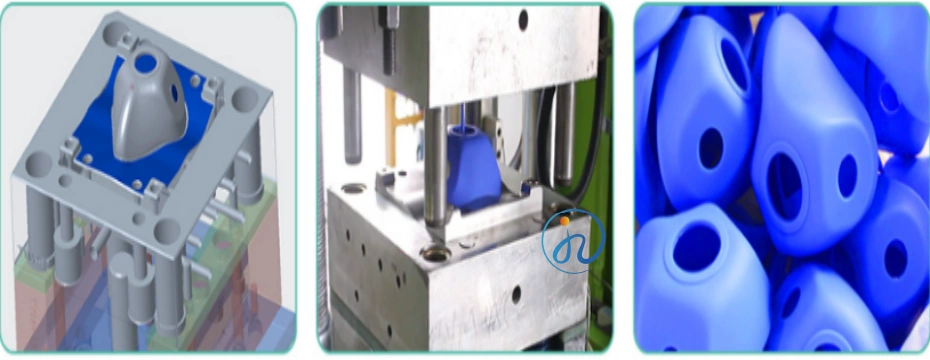

4. Tooling Design and Mold Engineering Support

LSR injection molding tooling is highly specialized due to:

- Cold runner systems

- Vacuum-assisted molding

- Precision venting

- Mold temperature control

- Automatic demolding design

An experienced LSR silicone molding partner provides:

- Professional mold flow analysis

- Optimal gate and runner design

- Flash-free mold structure

- Long-life tooling for mass production

This helps product designers avoid costly tooling mistakes and ensures the mold is built for stable, long-term production performance.

5. Process Optimization for Stable Mass Production

Even with a good design and mold, LSR injection molding requires precise control of:

- Injection speed

- Metering accuracy

- Mold temperature

- Cure time

- Demolding process

An LSR silicone molding partner supports product designers by:

- Developing stable molding parameters

- Conducting process validation (IQ/OQ/PQ)

- Ensuring repeatability across production batches

This is particularly important for medical, automotive, and industrial products where quality consistency is critical.

6. Overmolding and Multi-Material Integration

Many modern products require LSR overmolding on:

- Plastic substrates (PC, ABS, PBT, PA)

- Metal components

- Electronic housings

An experienced LSR molding partner helps product designers:

- Select compatible bonding materials

- Optimize surface treatment for adhesion

- Design mechanical locking structures

- Integrate sealing and functional components into one part

This reduces assembly steps, improves product reliability, and enhances overall product value.

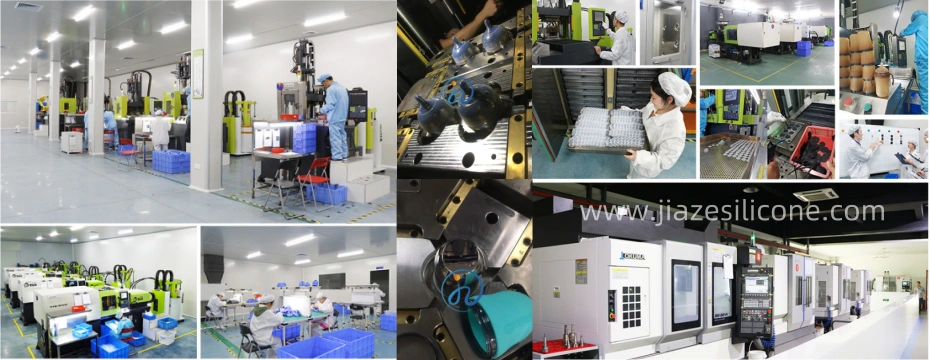

7. Quality Control and Regulatory Compliance

For regulated industries such as medical and food contact products, product designers must comply with:

- ISO 13485

- FDA requirements

- USP Class VI

- LFGB or FDA food contact regulations

An LSR silicone molding partner provides:

- Cleanroom molding capabilities

- Material traceability

- Validation documentation

- Process control systems

This helps designers ensure that their products meet regulatory standards and pass customer audits.

8. Cost Optimization and Scalability

One major concern for product designers is balancing innovation with manufacturing cost. An experienced LSR silicone molding partner helps reduce overall project investment by:

- Optimizing part design to reduce material usage

- Designing molds for multi-cavity production

- Automating demolding and inspection

- Reducing defect rates and scrap

From pilot production to high-volume manufacturing, a professional partner ensures scalability without compromising quality.

Key Benefits for Product Designers Working with an LSR Molding Partner

- Faster product development cycles

- Lower tooling and production risks

- Better part performance and durability

- Improved manufacturability

- Reduced time-to-market

- Stronger product competitiveness

How to Choose the Right LSR Silicone Molding Partner?

When selecting an LSR molding partner, product designers should evaluate:

- LSR molding experience and project portfolio

- Engineering support capability

- In-house tooling development

- Cleanroom and automation capability

- Quality system certifications

- Communication efficiency and responsiveness

A reliable partner is not just a supplier, but a technical extension of your product design team.

Conclusion: LSR Silicone Molding Partner as a Strategic Asset for Product Designers

In today’s competitive product development environment, product designers are expected to innovate faster, reduce cost, and ensure manufacturability at the same time. Working with a professional LSR silicone molding partner transforms the manufacturing phase from a risk into a strategic advantage.

From concept design, material selection, prototyping, tooling, and validation to mass production, an experienced LSR partner helps product designers bring ideas to life more efficiently, reliably, and competitively.

If you are developing products with Liquid Silicone Rubber, choosing the right LSR molding partner is not optional — it is a core success factor for your product’s commercial success.