Table of Contents

ToggleLiquid Silicone Rubber (LSR) injection molding has become a preferred manufacturing solution for medical devices, wearable electronics, baby products, automotive seals, and high-precision industrial components. However, the success of an LSR injection molding project depends heavily on the capabilities and support of the manufacturer you choose.

So, how can manufacturers support your LSR injection molding project effectively?

This guide explains the full support process—from concept and design to tooling, validation, mass production, and post-production services—helping OEMs and buyers choose the right LSR molding partner.

What Is LSR Injection Molding?

LSR injection molding is a highly automated process used to manufacture silicone rubber parts with excellent precision, repeatability, and cleanliness. LSR is a two-part platinum-cured silicone that offers:

- High transparency and purity

- Biocompatibility (medical-grade available)

- Heat and cold resistance

- Chemical stability

- Excellent elasticity and durability

Because of these properties, LSR injection molding is used in:

- Medical devices and healthcare components

- Respirator masks and seals

- Baby feeding products

- Consumer electronics seals

- Automotive connectors and gaskets

Why Manufacturer Support Is Critical in LSR Injection Molding Projects

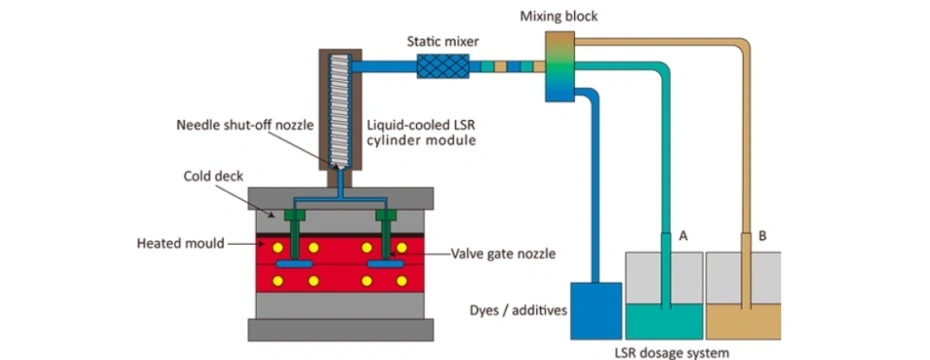

Unlike traditional rubber molding, LSR injection molding involves:

- Complex tooling design

- Specialized cold runner systems

- Strict material handling requirements

- Cleanroom production (for medical parts)

A professional manufacturer does more than just “produce parts.” They act as a technical partner, helping you avoid design flaws, reduce tooling risks, shorten lead times, and control total project cost.

1. Design for Manufacturing (DFM) Support

Early Engineering Involvement

The best LSR manufacturers provide DFM (Design for Manufacturing) support at the early design stage. This includes:

- Reviewing 2D drawings and 3D CAD files

- Optimizing part geometry for LSR flow

- Advising on wall thickness, undercuts, and draft angles

- Suggesting gate location and venting design

Material Selection Guidance

Manufacturers help you choose the right LSR grade based on:

- Medical, food-grade, or industrial standards

- Transparency or pigmentation requirements

- Hardness (Shore A)

- Tear strength and elongation

- Compliance with FDA, ISO 10993, LFGB, etc.

This technical support reduces redesign cycles and improves first-pass success.

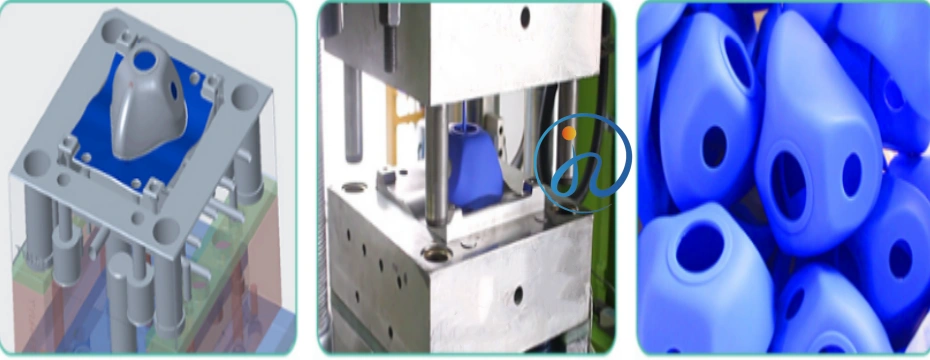

2. Professional LSR Tooling & Mold Design Support

Custom LSR Mold Engineering

LSR molds are highly specialized. A capable manufacturer supports your project by offering:

- Multi-cavity mold design

- Cold runner system integration

- Valve gate or open gate options

- Automatic demolding design

- Overmolding mold solutions (LSR + plastic)

Mold Flow Analysis

Advanced manufacturers use mold flow simulation to:

- Predict filling behavior

- Identify air traps and weld lines

- Optimize gate placement

- Reduce material waste

This engineering support improves mold performance and reduces trial-and-error costs.

3. Prototyping & Sampling Support

Rapid Prototyping

Before mass production, manufacturers often support projects with:

- Soft tooling

- Prototype molds

- Small-batch LSR molding

This allows you to:

- Validate part design

- Test fit and function

- Verify sealing performance

- Conduct regulatory testing

Sample Validation

Support includes:

- Dimensional inspection reports

- Material test reports

- Functional testing assistance

This stage helps prevent costly mistakes before full tooling investment.

4. Mass Production & Process Control Support

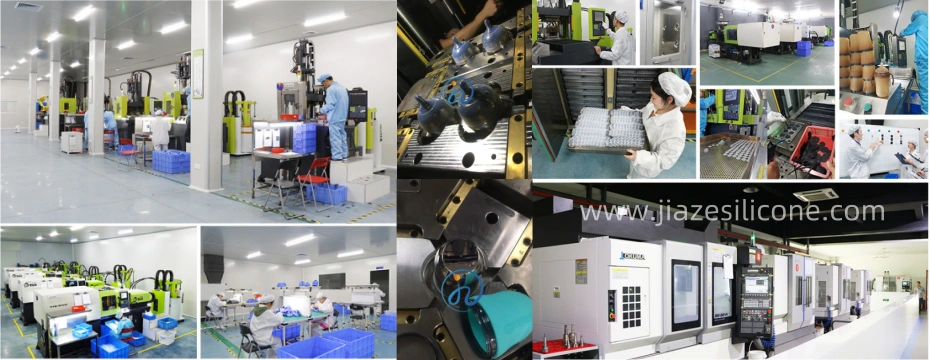

Automated LSR Injection Molding Production

Professional manufacturers support stable mass production with:

- Fully automated LSR injection molding machines

- Robotic demolding

- Vision inspection systems

- High-repeatability process parameters

Process Development & Optimization

Support includes:

- Optimizing injection speed, curing time, and temperature

- Process capability studies (Cp, Cpk)

- Cycle time reduction strategies

- Scrap rate reduction

This ensures consistent quality and cost efficiency.

5. Quality Control & Regulatory Compliance Support

Quality Management Systems

Reliable manufacturers provide:

- ISO 9001 quality systems

- ISO 13485 for medical device components

- Full traceability of raw materials

- Incoming, in-process, and final inspections

Compliance Support

Manufacturers can help ensure your LSR parts meet:

- FDA regulations

- LFGB / food contact standards

- RoHS & REACH

- Biocompatibility testing (for medical applications)

This support is crucial for medical, baby care, and food-grade silicone products.

6. Cleanroom Manufacturing Support (Medical LSR Projects)

For medical and healthcare products, many manufacturers offer:

- ISO Class 7 or Class 8 cleanroom LSR molding

- Controlled environment packaging

- Particle and contamination control

- Sterilization compatibility support

This ensures your LSR components are suitable for:

- Respirators

- Mask seals

- Medical valves

- Implant-adjacent components

7. Cost Optimization & Supply Chain Support

Cost Reduction Engineering

Manufacturers support your project by:

- Optimizing mold cavitation to reduce part cost

- Improving material utilization

- Reducing cycle time

- Proposing alternative LSR grades with similar performance

Stable Supply Chain Support

A reliable LSR molding partner helps with:

- Long-term production planning

- Inventory management

- Flexible MOQ for new projects

- Backup tooling strategies

This support improves supply chain stability and reduces procurement risks.

8. Secondary Operations & Assembly Support

Beyond molding, manufacturers often provide:

- Post-curing

- Trimming and deflashing

- Surface treatment

- Laser marking

- Part assembly (LSR + plastic or metal inserts)

This one-stop solution reduces coordination costs and simplifies your supplier base.

9. Project Management & Communication Support

A professional manufacturer supports your LSR project with:

- Dedicated project managers

- Regular production progress reports

- Engineering change management (ECN)

- Clear communication in English for international customers

Strong project management support helps ensure your project stays on schedule and within budget.

How to Choose the Right LSR Injection Molding Manufacturer?

When evaluating manufacturers, consider:

- Proven experience in LSR injection molding

- In-house mold design and tooling capabilities

- Medical or food-grade compliance experience

- Cleanroom facilities (if required)

- Engineering and DFM support

- Quality certifications

- Global customer service experience

Choosing the right partner directly impacts your product quality, cost structure, and time-to-market.

Conclusion

So, how can manufacturers support your LSR injection molding project?

From design optimization and tooling engineering to prototyping, mass production, quality assurance, and supply chain management, a professional LSR injection molding manufacturer plays a vital role as your long-term technical partner.

By working with an experienced LSR manufacturer, you can:

- Reduce development risk

- Shorten time-to-market

- Improve product quality

- Control production cost

- Ensure regulatory compliance

If you are developing medical devices, respirator masks, baby products, or precision silicone components, choosing a manufacturer with strong LSR injection molding support capabilities is the key to project success.