Table of Contents

ToggleSilicone injection tooling plays a critical role in the production of high-quality LSR rubber components. For product developers, procurement managers, and engineers, one of the most common questions is:

How long does it take to make silicone injection tooling?

The answer depends on multiple factors, including tooling complexity, material selection, design validation, and manufacturing capability. In this guide, we’ll walk through the complete silicone injection tooling timeline, explain what affects lead time, and show how manufacturers can optimize the process without sacrificing quality.

What Is Silicone Injection Tooling?

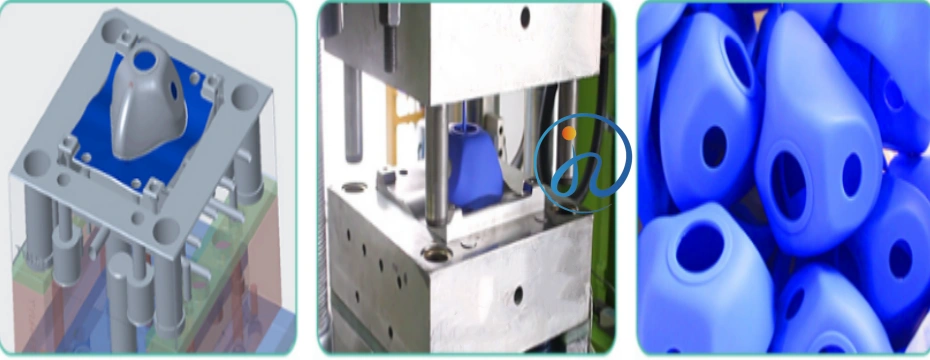

It refers to the precision molds used to manufacture LSR parts through the injection molding process. These tools are typically made from hardened steel or aluminum and are designed to handle:

- Liquid Silicone Rubber (LSR)

- High Consistency Rubber (HCR)

- Medical-grade or food-grade silicone materials

Because LSR behaves differently from thermoplastics, silicone injection tooling requires specialized design, including cold runner systems, precise venting, and temperature-controlled cavities.

Typical Lead Time for Silicone Injection Tooling

On average, silicone injection tooling takes 4 to 8 weeks to complete from design approval to first sample delivery.

General Timeline Overview

| Stage | Estimated Time |

|---|---|

| DFM & Mold Design | 7-15 days |

| Tool Steel Preparation | 3–5 days |

| CNC Machining | 15-20 days |

| EDM & Polishing | 5–10 days |

| Mold Assembly | 3–5 days |

| Trial & Sampling (T1) | 3–5 days |

Total Lead Time:

➡️ 40-60 days, depending on project complexity

Key Factors That Affect LSR Injection Tooling Lead Time

1. Tooling Complexity

The more complex the silicone part, the longer the tooling process.

Factors increasing complexity include:

- Multi-cavity molds

- Undercuts or complex geometries

- Thin-wall silicone components

- Integrated sealing or overmolding features

Simple single-cavity molds can be completed faster, while multi-cavity LSR molds may require additional weeks.

2. Part Design & DFM Approval

Design for Manufacturability (DFM) is often the first bottleneck.

If the CAD design:

- Has insufficient draft angles

- Lacks proper venting locations

- Includes unrealistic tolerances

Then revisions are required, extending the tooling timeline. A fast DFM approval can save 5–10 days.

3. Tooling Material Selection

Different tooling materials affect machining speed and durability.

| Tooling Material | Lead Time Impact |

|---|---|

| Aluminum Tooling | Faster (prototype tooling) |

| P20 Steel | Standard lead time |

| H13 / Hardened Steel | Longer machining time |

For mass production silicone injection tooling, hardened steel is preferred, even though it increases lead time slightly.

4. Cold Runner vs Hot Runner System

Silicone injection tooling often uses cold runner systems, which require:

- Higher precision machining

- Thermal insulation

- Additional validation

Hot runner silicone molds reduce material waste but increase tooling design and manufacturing time due to complexity.

5. Surface Finish & Polishing Requirements

Silicone parts are highly sensitive to surface finish.

Common finishes include:

- SPI-A1 (mirror polish)

- Matte or textured finishes

- Medical-grade surface standards

High-polish silicone injection tooling may require extra EDM and polishing time, adding 3–7 days.

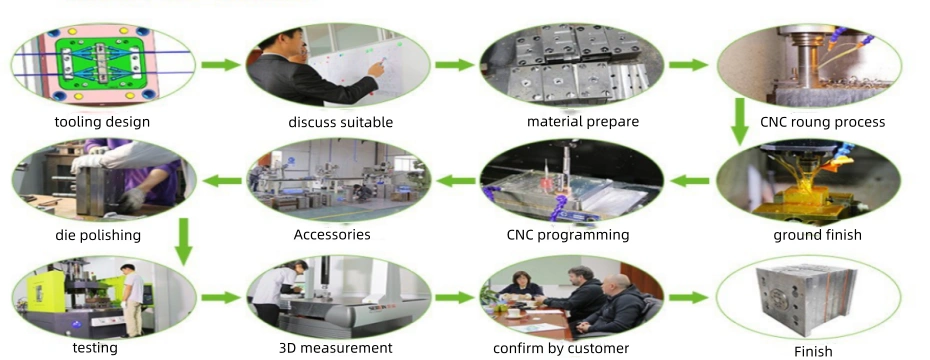

Step-by-Step Silicone Injection Tooling Manufacturing Process

Step 1: DFM Analysis & Mold Design

Time: 3–7 days

Engineers review:

- Part geometry

- Gate location

- Venting strategy

- Shrinkage compensation

A detailed mold flow and design approval is completed before machining begins.

Step 2: Tool Steel Preparation

Time: 3–5 days

Steel blocks are:

- Cut to size

- Heat-treated if required

- Stress-relieved to prevent deformation

This step ensures dimensional stability during CNC machining.

Step 3: CNC Machining & EDM

Time: 7–14 days

This is the most time-consuming stage:

- High-speed CNC milling for cavities

- EDM for sharp corners and fine features

- Precision drilling for runner systems

Advanced 5-axis CNC machines can significantly reduce this time.

Step 4: Polishing & Surface Treatment

Time: 5–10 days

The surface quality directly affects:

- Part appearance

- Demolding performance

- Flash control

Medical and food-grade tooling often requires manual polishing under strict standards.

Step 5: Mold Assembly & Fitting

Time: 3–5 days

Components are assembled and tested:

- Alignment of core and cavity

- Runner sealing

- Temperature control channels

Any fitting issues are corrected before trials.

Step 6: Mold Trial & First Sampling (T1)

Time: 3–5 days

The mold is tested using actual silicone material to:

- Validate filling balance

- Check flash and parting lines

- Measure dimensional accuracy

After T1, adjustments may be needed before final approval.

How to Reduce Silicone Injection Tooling Lead Time

1. Provide Complete CAD Files Early

- STEP or IGES formats

- Clear tolerance requirements

- Material specifications

2. Approve DFM Quickly

Fast feedback during DFM review can reduce tooling lead time by up to 30%.

3. Choose an Experienced Silicone Tooling Manufacturer

An experienced supplier:

- Avoids design mistakes

- Uses optimized machining paths

- Has in-house trial molding capability

This reduces back-and-forth delays.

4. Use Modular Mold Design

Modular it allows:

- Faster cavity changes

- Easier maintenance

- Shorter future lead times

Common Questions About Silicone Injection Tooling Lead Time

Is silicone injection tooling slower than plastic?

Not necessarily. While silicone molds are more specialized, experienced manufacturers can match plastic tooling timelines for standard designs.

Can LSR injection tooling be expedited?

Yes. With expedited machining and parallel processes, tooling can be completed in as little as 10–15 days for simple designs.

Does medical-grade silicone tooling take longer?

Often yes, due to:

- Higher surface finish requirements

- Validation documentation

- Cleanroom trial molding

Conclusion: How Long Does Silicone Injection Tooling Really Take?

In most cases, it takes between 4 and 8 weeks, depending on design complexity, material requirements, and tooling standards.

By working with an experienced silicone injection molding manufacturer and optimizing the design and approval process, lead time can be significantly reduced—without compromising quality or performance.

If you’re planning a silicone injection molding project, understanding the tooling timeline upfront helps you control costs, avoid delays, and accelerate time to market.