Table of Contents

ToggleWhen developing liquid silicone rubber parts, one of the first and most important questions buyers ask is:

How much does it cost to make an LSR molding mold?

The cost of an LSR molding mold can vary widely depending on design complexity, mold structure, cavity count, material selection, and production requirements. In this guide, we’ll break down the real cost of LSR molding molds, explain what drives pricing, and help you estimate your project budget more accurately.

What Is an LSR Molding Mold?

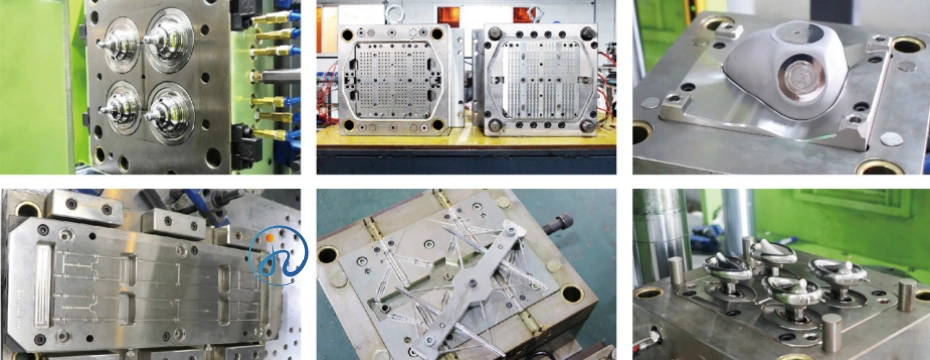

An LSR molding mold is a precision tool used in the liquid silicone rubber (LSR) injection molding process. Unlike conventional plastic molds, LSR molds must handle:

- Two-component liquid silicone materials

- Cold runner or hot runner systems

- Precise temperature control

- Flash-free and high-precision sealing designs

LSR molding molds are widely used in medical devices, automotive parts, baby products, electronics sealing, and consumer goods.

Average Cost of an LSR Molding Mold

In general, the cost to make an LSR molding mold ranges from:

Typical Price Range

- Simple prototype mold: USD 2,000 – 5,000

- Standard production mold: USD 5,000 – 15,000

- Complex multi-cavity mold: USD 15,000 – 50,000+

The final price depends on multiple technical and production factors, which we’ll explain in detail below.

Key Factors That Affect LSR Molding Mold Cost

1. Part Design Complexity

Complexity is the number one cost driver.

LSR parts with the following features increase mold cost:

- Thin walls or micro features

- Complex geometries or undercuts

- Tight tolerances

- Integrated sealing lips

The more complex the part design, the more advanced machining, EDM work, and fitting are required.

2. Mold Cavity Number

The number of cavities directly impacts tooling cost.

| Cavity Type | Cost Impact |

|---|---|

| Single cavity | Lowest cost |

| 2–4 cavities | Moderate increase |

| 8+ cavities | High tooling cost |

Multi-cavity LSR molding molds increase productivity but also require:

- More precise balance control

- Higher machining time

- More complex runner systems

3. Mold Material Selection

The steel or aluminum used for the mold base and cavities significantly affects price.

| Mold Material | Cost Level | Application |

|---|---|---|

| Aluminum | Low | Prototyping |

| P20 Steel | Medium | Low-volume production |

| H13 / Hardened Steel | High | Mass production |

High-volume LSR molding molds usually require hardened steel for durability, increasing upfront cost but reducing long-term maintenance.

4. Cold Runner vs Hot Runner System

LSR molds typically use cold runner systems, but hot runner options are also available.

Cold Runner LSR Mold

- Lower initial cost

- Some material waste

- Simpler design

Hot Runner LSR Mold

- Higher tooling cost

- Minimal material waste

- Better for high-volume production

Hot runner LSR molding molds can increase tooling cost by 20–40% due to system complexity.

5. Surface Finish & Polishing Requirements

LSR parts are extremely sensitive to surface finish.

Higher polish levels mean:

- More manual polishing hours

- Higher labor costs

- Longer lead times

Medical-grade or food-grade LSR molding molds often require mirror polishing (SPI-A1), increasing tooling cost.

6. Tolerance & Quality Standards

Tighter tolerances = higher cost.

Industries such as:

- Medical

- Automotive

- Electronics

Require stricter dimensional control, inspection, and documentation, all of which add to the total mold price.

Cost Breakdown of an LSR Molding Mold

Here’s how the total cost is typically distributed:

| Cost Item | Percentage |

|---|---|

| Mold design & DFM | 10–15% |

| CNC machining | 30–40% |

| EDM & precision work | 15–20% |

| Polishing & surface finish | 10–15% |

| Assembly & testing | 10–15% |

Understanding this breakdown helps buyers identify where costs can be optimized.

Prototype vs Production LSR Molding Mold Cost

Prototype LSR Mold

- Lower tooling cost

- Shorter lead time

- Limited mold life

Best for: Product validation, market testing

Production LSR Mold

- Higher upfront cost

- Long mold life

- Stable mass production

Best for: Long-term manufacturing

Choosing the right mold type early can save thousands of dollars.

How to Reduce LSR Molding Mold Cost

1. Optimize Part Design

Simple design changes can reduce mold cost:

- Avoid unnecessary undercuts

- Increase wall thickness where possible

- Reduce tight tolerance zones

2. Start with a Prototype Mold

Prototype tooling allows design validation before investing in expensive production molds.

3. Choose the Right Cavity Count

More cavities ≠ lower cost initially.

Balance tooling investment with expected production volume.

4. Work with an Experienced LSR Mold Manufacturer

An experienced supplier:

- Avoids design errors

- Optimizes runner and venting design

- Reduces costly revisions

This can lower total project cost even if the initial quote seems higher.

Hidden Costs to Watch Out For

When budgeting for an LSR molding mold, consider:

- Mold modification costs

- Maintenance and spare parts

- Shipping and customs fees

- Validation or compliance documentation

A transparent supplier will clarify these costs upfront.

Conclusion: How Much Should You Budget for an LSR Molding Mold?

The cost to make an LSR molding mold typically ranges from USD 2,000 to over USD 50,000, depending on complexity, cavity count, materials, and production requirements.

By understanding the pricing structure and working with the right LSR molding partner, you can control tooling costs, shorten development cycles, and achieve reliable mass production.

A well-designed LSR molding mold is not just a cost—it’s a long-term investment in product quality and manufacturing stability.