Table of Contents

ToggleLiquid Silicone Rubber (LSR) injection molding is used for producing high-precision silicone parts for medical devices, automotive sealing systems, consumer electronics, and industrial components. One of the most common questions from OEMs and product designers is:

“How much tolerance can LSR injection molding meet?”

Understanding achievable tolerances is critical for ensuring part fit, sealing performance, assembly compatibility, and overall product reliability. In this article, we explain the realistic tolerance capabilities of LSR injection molding, the key factors that influence dimensional accuracy, and practical design guidelines to achieve tight tolerances in mass production.

What Is Tolerance in LSR Injection Molding?

Tolerance refers to the allowable variation in a part’s dimensions during manufacturing. Because LSR is an elastomer with flexibility, thermal expansion, and post-curing shrinkage characteristics, tolerances in silicone molding differ from rigid thermoplastics.

In LSR injection molding, tolerances are affected by:

- Material shrinkage

- Mold precision

- Process stability

- Part geometry

- Demolding behavior

- Environmental conditions

Unlike CNC-machined metal parts, molded silicone components require tolerance standards specifically suited to elastomeric materials.

Typical Tolerance Range for LSR Injection Molding

General Industry Tolerances

For standard LSR injection molded parts, typical achievable tolerances are:

- Linear dimensions: ±0.05 mm to ±0.10 mm

- Critical sealing features: ±0.03 mm to ±0.05 mm (with optimized tooling and process control)

- Wall thickness: ±10% (depending on part size and geometry)

These tolerances are suitable for most:

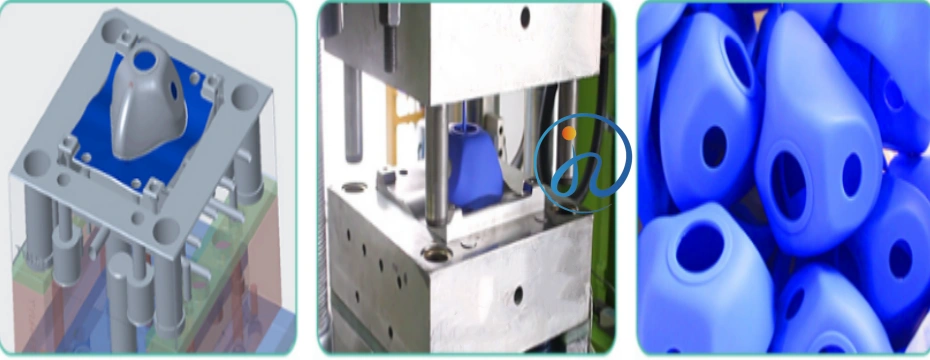

- Medical silicone components

- Mask seals and respirator parts

- O-rings and gaskets

- Consumer electronics sealing parts

High-Precision LSR Molding

With advanced tooling, mold flow optimization, and strict process control, some manufacturers can achieve:

- Micro-feature tolerances: ±0.02 mm to ±0.03 mm

- Multi-cavity consistency: Part-to-part deviation within ±0.03 mm

However, such tight tolerances usually require:

- Premium mold steel

- Precision machining

- Tight temperature control

- Automated demolding

- Statistical process control (SPC)

Key Factors That Affect LSR Injection Molding Tolerances

1. LSR Material Shrinkage

LSR typically exhibits low but measurable shrinkage, often in the range of:

- 2.5% to 3.5% (depending on grade and curing conditions)

Although LSR shrinkage is more stable than many rubber materials, variations in:

- Curing temperature

- Mold temperature

- Post-curing process

can affect final part dimensions.

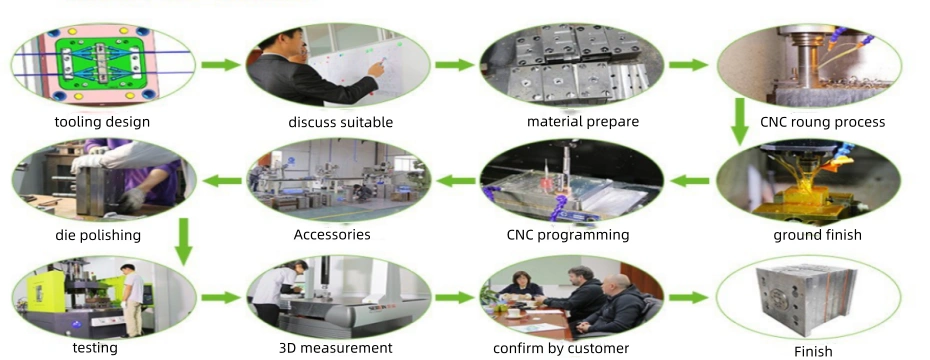

2. Mold Design and Tooling Precision

High-precision LSR tolerances rely heavily on mold quality:

- Precision cavity machining

- Accurate parting line design

- Optimized venting

- Stable cold runner systems

- Minimal mold wear

A well-designed LSR mold ensures consistent cavity fill and repeatable part dimensions over long production runs.

3. Part Geometry and Design Complexity

Complex geometries increase tolerance challenges:

- Thin walls may deform during demolding

- Large flat surfaces may warp

- Deep ribs and undercuts affect dimensional stability

Design features such as:

- Uniform wall thickness

- Proper draft angles

- Balanced geometry

help improve tolerance consistency.

4. Process Parameters and Production Stability

LSR injection molding tolerances are influenced by:

- Injection speed

- Metering accuracy of two-component LSR

- Mold temperature

- Curing time

- Demolding force

Professional manufacturers control these parameters using:

- Closed-loop injection systems

- Automated dosing units

- Process monitoring systems

This ensures dimensional stability from batch to batch.

5. Demolding and Post-Processing

Because LSR parts are flexible, dimensional deviation can occur during:

- Demolding

- Trimming

- Post-curing

- Packaging and storage

Support fixtures and automated demolding systems help reduce deformation and improve dimensional repeatability.

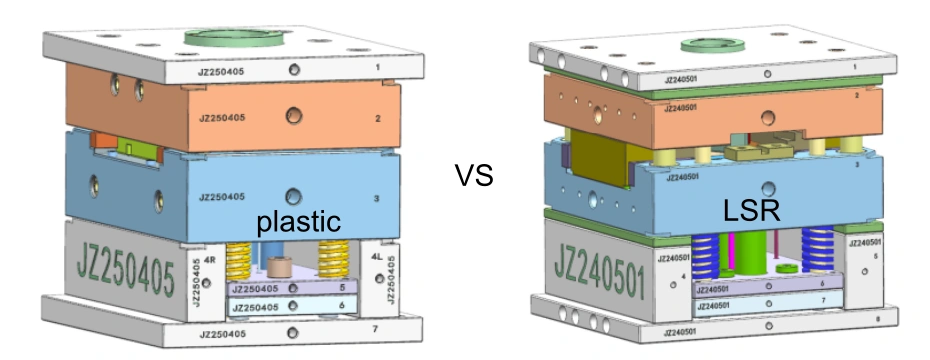

LSR Tolerance vs Thermoplastic Injection Molding

It is important to set realistic expectations when comparing LSR injection molding with plastic injection molding:

| Feature | LSR Injection Molding | Thermoplastic Injection Molding |

|---|---|---|

| Typical tolerance | ±0.05–0.10 mm | ±0.02–0.05 mm |

| Material behavior | Elastic | Rigid |

| Post-curing effect | Possible | None |

| Demolding deformation | Higher risk | Lower risk |

| Sealing performance | Excellent | Limited |

While plastics may achieve tighter absolute tolerances, LSR parts often compensate with superior sealing, elasticity, and tolerance to compression.

Tolerance Standards for LSR Molded Parts

Many manufacturers follow general elastomer tolerance standards such as:

- ISO 3302-1 (Rubber products – Tolerances)

- DIN ISO 3302

- Internal tolerance standards for medical LSR components

For medical and sealing applications, functional tolerances are often more important than absolute dimensional tolerances.

How to Achieve Tight Tolerances in LSR Injection Molding Projects

1. Involve the Manufacturer Early (DFM Support)

Early DFM (Design for Manufacturing) reviews help:

- Optimize part geometry

- Adjust tolerance requirements to realistic ranges

- Reduce tooling revisions

2. Specify Critical Dimensions Only

Avoid applying tight tolerances to non-critical features. Focus tight tolerances on:

- Sealing lips

- Mating surfaces

- Snap-fit features

- Assembly interfaces

This reduces tooling cost and improves overall yield.

3. Use Precision Tooling and Mold Flow Analysis

High-precision molds and simulation tools help:

- Balance filling

- Reduce internal stress

- Improve dimensional stability

4. Implement SPC and Process Validation

Manufacturers can support tight tolerance requirements by:

- Using Statistical Process Control (SPC)

- Conducting process capability studies (Cp, Cpk)

- Implementing IQ/OQ/PQ validation (for medical projects)

5. Material and Post-Cure Control

Controlling:

- LSR grade

- Cure profile

- Post-curing process

helps stabilize final dimensions, especially for medical-grade LSR parts.

Typical Tolerance Requirements by Application

| Application | Typical Tolerance Requirement |

|---|---|

| Medical device seals | ±0.03–0.05 mm |

| Respirator mask sealing parts | ±0.05 mm |

| Baby product silicone components | ±0.05–0.10 mm |

| Industrial gaskets | ±0.05–0.10 mm |

| Consumer electronics seals | ±0.03–0.05 mm |

These values vary based on part size and geometry but reflect common industry practice.

Common Tolerance Challenges in LSR Injection Molding

- Flashing on parting lines

- Dimensional variation across cavities

- Shrinkage inconsistency

- Warping in thin sections

- Compression set affecting sealing performance

Experienced manufacturers address these challenges through mold optimization, automated process control, and continuous quality monitoring.

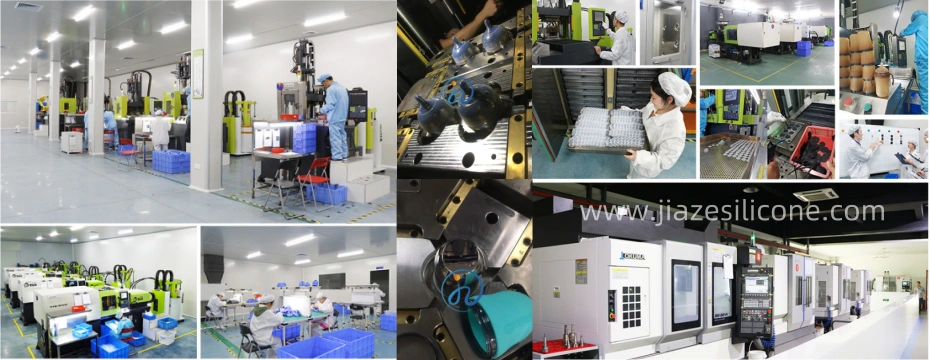

How a Professional LSR Manufacturer Supports Tolerance Control

A qualified LSR injection molding manufacturer supports tight tolerance requirements by providing:

- DFM and tolerance stack-up analysis

- Precision mold design and fabrication

- Mold flow simulation

- Automated LSR injection molding equipment

- Cleanroom production (for medical LSR)

- In-process inspection and SPC

- Dimensional reports and PPAP-style documentation

This integrated support ensures your tolerance requirements are met consistently in mass production.

Conclusion

So, how much tolerance can LSR injection molding meet?

In most applications, ±0.05 mm to ±0.10 mm is a realistic and stable tolerance range for LSR injection molded parts. With advanced tooling, optimized design, and professional process control, tighter tolerances down to ±0.02–0.03 mm can be achieved for critical features.

To achieve reliable results, it is essential to work with an experienced LSR injection molding manufacturer who can support your project from design and tooling to process validation and quality control.

If your application requires high-precision medical, sealing, or wearable silicone components, early collaboration with a professional LSR molding partner will significantly improve tolerance performance and overall project success.