Table of Contents

ToggleLiquid Silicone Rubber (LSR) injection molding is a specialized manufacturing process used to produce high-precision, durable, and flexible components for industries like medical, automotive, and consumer electronics. As demand for LSR products grows, becoming a suitable LSR injection manufacturer requires more than just owning machinery—it demands technical expertise, stringent quality control, and a deep understanding of material science.

In this guide, we’ll explore the key factors that define a reliable LSR injection manufacturer and how to position your business to meet industry standards and client expectations.

What Is LSR Injection Molding?

LSR injection molding involves injecting liquid silicone rubber into a mold cavity under high pressure and temperature. The material then vulcanizes (cures) to form a solid, flexible part with excellent thermal stability, biocompatibility, and resistance to chemicals and weathering. Unlike solid silicone, LSR is supplied in liquid form, making it ideal for complex geometries and high-volume production.

Key Attributes of a Top-Tier LSR Injection Manufacturer

Advanced Equipment and Technology

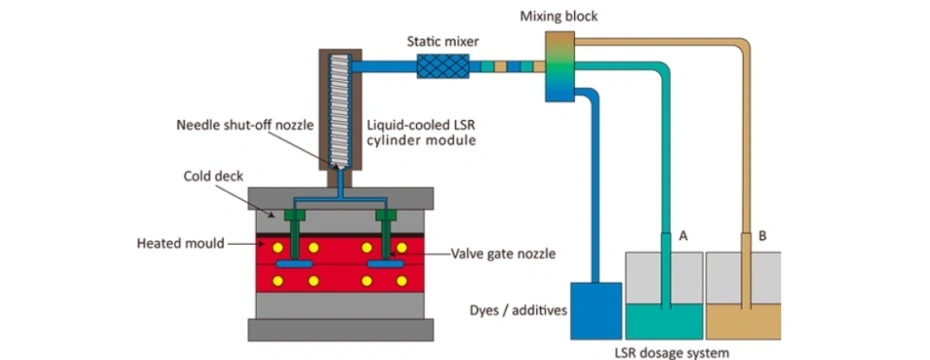

LSR injection molding requires specialized machinery, including:

- Cold-runner injection molding systems to minimize waste.

- Precision molds with temperature-controlled systems.

- Automated equipment for consistency and efficiency.

Material Expertise

Not all LSR is created equal. A suitable manufacturer must understand:

Material properties (e.g., viscosity, hardness, curing time).

Compliance with industry-specific standards (e.g., USP Class VI for medical-grade LSR).

Customization options for color, additives, and performance enhancements.

Stringent Quality Control

Quality is non-negotiable in industries like medical and automotive. Implement:

In-process inspections during molding.

Post-production testing (e.g., tensile strength, elongation, biocompatibility).

Certifications like ISO 13485 (medical devices) and IATF 16949 (automotive).

Design and Engineering Support

Clients often need guidance with design for manufacturability (DFM). Offer:

Mold flow analysis to predict filling and curing behavior.

Prototyping services to validate designs before mass production.

Expertise in mitigating common issues like air traps or incomplete curing.

Industry-Specific Experience

Different sectors have unique requirements:

- Medical: Sterilization compatibility, biocompatibility.

- Automotive: Resistance to extreme temperatures and fluids.

- Consumer Electronics: Precision, aesthetics, and durability.

Supply Chain and Scalability: Reliable manufacturers must:

Source high-quality raw materials consistently.

Handle large-volume orders without compromising turnaround times.

Provide transparent communication throughout production.

Sustainability Practices

Eco-friendly initiatives, such as recycling silicone waste and optimizing energy use, are increasingly important to clients.

How to Choose the Right LSR Injection Manufacturer

If you’re a business looking for a manufacturer, consider:

- Certifications: Ensure they meet relevant industry standards.

- Portfolio: Review past projects similar to your needs.

- Testing Capabilities: Ask about their quality assurance processes.

- Communication: responsiveness and willingness to collaborate.

Conclusion

Becoming a suitable LSR injection manufacturer requires a blend of advanced technology, material knowledge, quality focus, and industry experience. By investing in these areas, manufacturers can meet the growing demand for high-performance LSR components and stand out in a competitive market.

For businesses seeking a partner, prioritize manufacturers with proven expertise, certifications, and a commitment to quality.