Table of Contents

ToggleAs the demand for high-performance silicone components rises across industries—medical, automotive, baby care, and consumer electronics—the need for reliable silicone parts manufacturers continues to grow. But becoming a trusted silicone injection parts manufacturer requires more than just buying machines. It takes technical expertise, precision tooling, strict quality standards, and a long-term strategy.

In this article, we’ll explore how to start and grow a successful silicone injection molding business and establish yourself as a reliable silicone parts manufacturer.

1. Understanding the Market Demand for Silicone Parts

Before you begin, it’s essential to study the market applications and target industries for silicone components. Silicone is known for its:

- Excellent heat resistance

- Biocompatibility

- Flexibility and durability

- Chemical and UV resistance

Common products include:

- Baby pacifiers and teething toys

- Medical devices and respiratory masks

- Automotive gaskets and seals

- Consumer electronics keypads and covers

- Kitchenware and pet products

Identifying your niche—whether it’s medical-grade, food-grade, or industrial-grade parts—is critical.

2. Choose the Right Silicone Molding Process

There are several manufacturing methods for silicone parts, but for high-volume and precision products, liquid silicone rubber (LSR) injection molding is the most efficient and scalable.

Most Common Processes:

- LSR Injection Molding – Fully automated, precise, ideal for complex, high-volume parts

- Compression Molding – Suitable for large, simple parts in small volumes

- Transfer Molding – A hybrid method, less automated, moderate precision

If your goal is to be a professional silicone parts manufacturer, investing in LSR injection molding is highly recommended.

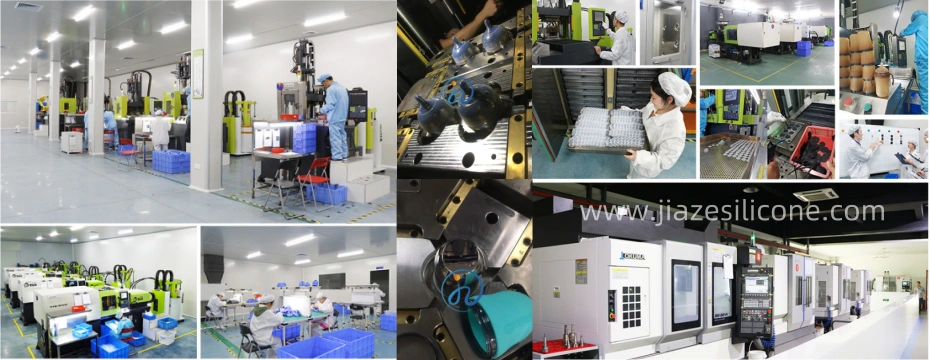

3. Set Up a Silicone Injection Molding Facility

A modern manufacturing plant should be equipped with:

- LSR injection molding machines (from 30T to 300T depending on part size)

- Two-component dosing and mixing systems

- Temperature-controlled molds (usually 160–220°C)

- Dust-free or cleanroom environment (especially for medical/food applications)

Also, consider:

- Automation systems for demolding and inspection

- Dehumidifiers and temperature controllers for material prep

- Tool maintenance and cleaning area

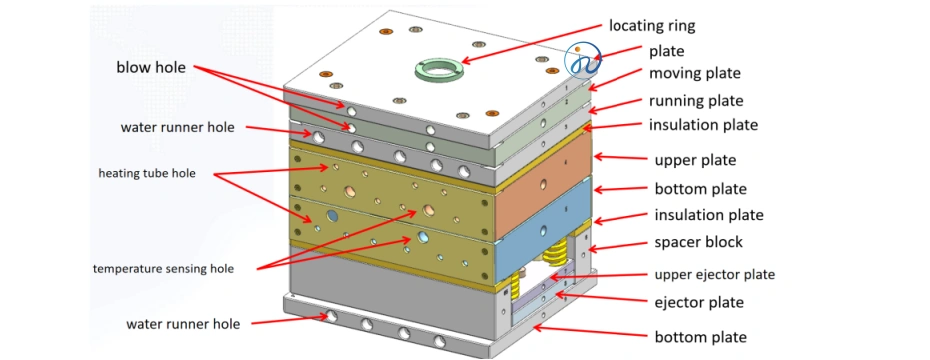

4. Invest in High-Quality Tooling Design and Fabrication

Tooling is the heart of silicone injection molding. Without precision molds, your product quality will suffer.

You’ll need:

- Experienced mold designers familiar with LSR material flow

- High-precision CNC machines and EDM equipment

- Steel molds (S136, H13, or stainless steel) with cold runner systems

- Multi-cavity tooling for large batch production

Your mold shop can be in-house or outsourced to a reliable mold maker.

5. Understand the Silicone Material Supply Chain

As a silicone parts manufacturer, having a steady supply of high-quality LSR or HCR silicone is vital.

Major suppliers include:

- Dow Corning

- Wacker Chemie

- Momentive

- Shin-Etsu

- Bluestar

Different grades of silicone (medical, food, flame-retardant, etc.) should be tested and validated before use.

6. Hire and Train Skilled Staff

Your team should include:

- Injection molding operators trained in LSR processing

- Mold engineers for tooling adjustments and maintenance

- Quality inspectors for dimensional and appearance checks

- R&D and design engineers for custom project development

- Sales and customer support for OEM/ODM clients

Investing in ongoing training is crucial for quality and productivity.

7. Establish Quality Control Systems

A successful silicone parts manufacturer must meet strict quality standards. Set up a full QC process including:

- Incoming material inspection

- In-process monitoring (temperature, pressure, curing time)

- Final product inspection (appearance, size, function)

- ISO certifications (ISO 9001, ISO 13485 for medical, FDA, RoHS, REACH)

Use tools like:

- Vision measuring systems (2.5D, 3D)

- Tensile testers

- Hardness testers (Shore A/D)

- Aging and heat resistance testing equipment

8. Build a Flexible and Scalable Production System

As orders grow, you must be able to scale your operations. Start with flexible batch sizes and:

- Modular molds (interchangeable cavities and cores)

- Multi-shot or two-shot molding for overmolded parts

- Customized tooling for different product lines

- ERP systems for production tracking and inventory management

Being able to switch between small and large batch production helps attract a wider range of clients.

9. Develop Strong Customer Relationships

To grow your brand as a silicone parts manufacturer, customer service is just as important as production. Provide:

- Rapid prototyping and sample turnaround

- Transparent communication and technical support

- On-time delivery with flexible logistics

- After-sales support and defect handling

Building long-term OEM/ODM partnerships increases client retention and brand reputation.

10. Market Your Silicone Manufacturing Business

Use online and offline strategies:

- Build a professional website with SEO-optimized product pages

- Highlight capabilities like “medical-grade LSR molding” or “custom silicone parts”

- Create content: blogs, white papers, and case studies

- List on B2B platforms (Alibaba, Global Sources, Made-in-China)

- Attend trade shows (e.g., MEDICA, K Show, Silicone Expo)

11. Ensure Compliance with Global Standards

To export your silicone parts worldwide, stay compliant with:

- FDA 21 CFR 177.2600 for food contact silicone

- ISO 10993 for medical biocompatibility

- REACH & RoHS for environmental safety in the EU

- UL94 for flame retardancy in electronics

Providing full documentation and testing reports builds trust with global clients.

12. Continuous Improvement and Innovation

As a long-term silicone parts manufacturer, stay ahead of the competition by:

- Investing in R&D to improve material performance

- Exploring micro-molding for miniature components

- Testing smart silicone materials (e.g., conductive or self-healing silicones)

- Incorporating AI/IoT in quality control or automation

Innovation can open doors to premium markets and larger clients.

Conclusion: Becoming a Trusted Silicone Parts Manufacturer

Becoming a reliable silicone parts manufacturer is a journey that involves technical knowledge, capital investment, and a customer-first mindset. From understanding silicone materials and molding technology to building a clean production environment and quality management system, every step matters.

Whether you’re starting small or aiming to be a global OEM supplier, focus on precision, quality, and service — and your reputation in the silicone industry will grow.