Table of Contents

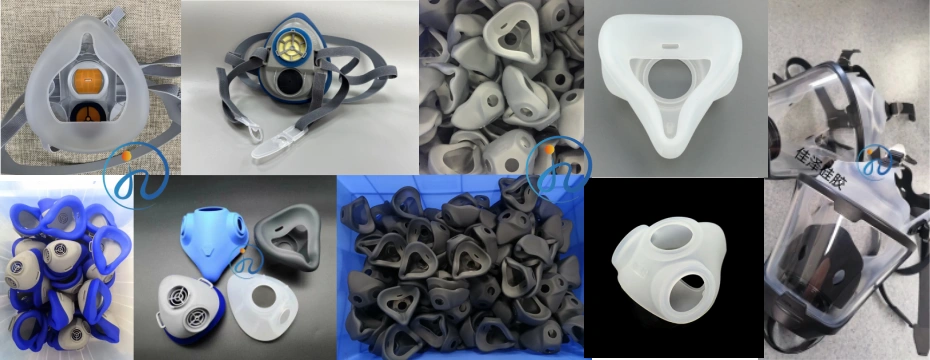

ToggleSilicone rubber gas mask respirators are used in industrial safety, medical protection, emergency response, and military equipment. Compared with traditional rubber or PVC masks, silicone respirators provide superior comfort, skin-friendliness, chemical resistance, and long-term durability.

For brands, PPE importers, and product designers, customizing a silicone rubber gas mask respirator is not just about appearance—it involves material selection, ergonomic design, filtration compatibility, mold development, manufacturing process control, and quality compliance.

1. What Is a Silicone Rubber Gas Mask Respirator?

A silicone rubber gas mask respirator is a personal protective device made mainly from liquid silicone rubber (LSR). It forms a tight seal on the user’s face and connects with filter cartridges to protect against:

- Toxic gases and vapors

- Dust and particulate matter

- Chemical fumes

- Biological contaminants

Key Components:

- Silicone facepiece (half mask or full face mask)

- Filter cartridge interface (bayonet or threaded type)

- Valve system (inhalation and exhalation valves)

- Head straps or harness

- Optional transparent silicone visor (for full-face masks)

2. Why Choose Silicone Rubber for Gas Mask Respirators?

Choosing the right material is critical for performance and user safety. Silicone rubber offers several advantages over traditional materials:

Superior Comfort & Skin Safety

Medical-grade or food-grade silicone is hypoallergenic, odorless, and non-toxic, making it suitable for long-term skin contact.

Excellent Sealing Performance

LSR provides high elasticity and resilience, ensuring a tight facial seal across different face shapes.

Chemical & Temperature Resistance

Silicone can withstand harsh chemicals, UV exposure, and extreme temperatures (-40°C to 200°C), ideal for industrial and emergency use.

Long Service Life

Unlike TPE or PVC, silicone rubber resists aging, cracking, and deformation over time.

3. Typical Applications of Custom Silicone Gas Mask Respirators

Custom silicone respirators are widely used in multiple industries:

- Industrial safety protection

- Chemical manufacturing plants

- Mining and construction

- Firefighting and emergency response

- Medical and laboratory environments

- Military and defense equipment

Customization allows brands to adapt respirators for specific standards, markets, and user scenarios.

4. Step-by-Step Process to Custom Silicone Rubber Gas Mask Respirator

4.1 Product Design & Requirement Definition

Before manufacturing, clarify the following:

- Target market (industrial, medical, military, consumer PPE)

- Mask type (half face mask or full face respirator)

- Face fit requirements (ergonomic design)

- Filter interface standard (EN, NIOSH, bayonet, threaded)

- Logo branding and color customization

- Compliance standards (CE, FDA, NIOSH, ISO, etc.)

Professional LSR manufacturers usually provide DFM (Design for Manufacturing) support to optimize the design for molding and mass production.

4.2 Material Selection (LSR Grade & Hardness)

Selecting the right silicone grade directly affects comfort and sealing performance.

Key material parameters:

- Medical-grade or industrial-grade LSR

- Shore hardness (usually Shore A 30–50 for face seals)

- Transparency or color pigmentation

- Biocompatibility requirements

- Chemical resistance properties

A qualified manufacturer can recommend suitable silicone formulations based on your application.

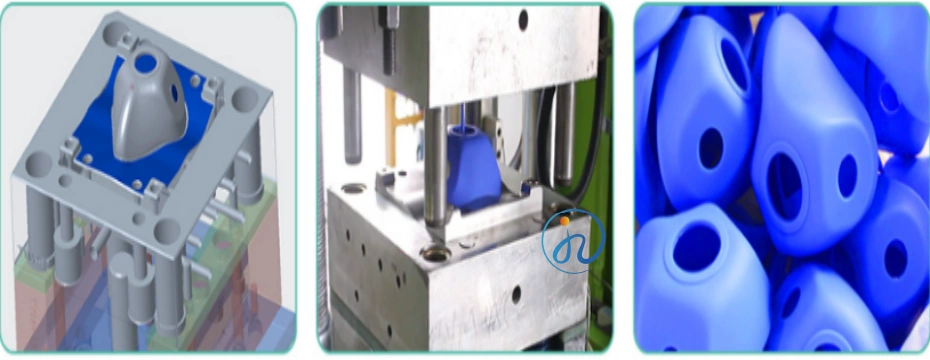

4.3 Mold Design & Tooling Development

Custom silicone gas mask respirators require precision injection molds:

- Multi-cavity molds for mass production

- High-precision steel tooling

- Cold runner systems for LSR

- Valve integration and overmolding design

- Transparent silicone molding for full-face visors

Proper mold design ensures:

- Stable part dimensions

- Minimal flash

- High surface finish

- Consistent sealing performance

4.4 LSR Injection Molding Process

Liquid Silicone Rubber injection molding is the most suitable manufacturing process for respirator facepieces:

- Automated LSR dosing and mixing

- Closed mold system for clean production

- High repeatability and dimensional accuracy

- Short cycle times for large volume orders

- Suitable for cleanroom manufacturing environments

For medical or PPE-grade products, LSR injection molding is preferred due to its cleanliness and stability.

4.5 Secondary Processing & Assembly

After molding, additional processes may include:

- Trimming and surface finishing

- Valve assembly

- Strap and harness installation

- Filter connector assembly

- Logo marking or laser engraving

A professional factory offers complete assembly service to deliver ready-to-use respirator products.

5. Quality Control & Compliance Standards

Quality control is critical for protective equipment. Key inspection steps include:

- Dimensional measurement

- Air leakage test

- Fit test and sealing performance test

- Material hardness and tensile strength test

- Aging and fatigue test

- Valve function testing

Common Certifications:

- CE (EN 140 / EN 136)

- NIOSH (USA)

- FDA (for medical respirators)

- ISO 13485 (medical device manufacturing)

Working with a certified silicone respirator manufacturer ensures compliance with global PPE standards.

6. Cost Factors of Custom Silicone Gas Mask Respirators

Cost depends on multiple factors:

- Mold tooling cost (one-time investment)

- LSR material grade

- Product structure complexity

- Annual order volume

- Certification and testing fees

- Packaging and branding requirements

Although silicone tooling cost is higher than TPE or PVC, long-term durability and product premium positioning often justify the investment.

7. How to Choose the Right Custom Silicone Respirator Manufacturer?

When selecting a manufacturing partner, consider:

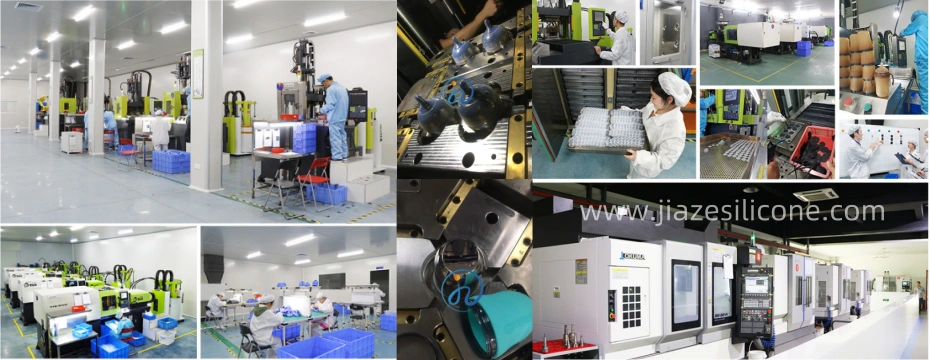

- Experience in LSR injection molding

- Cleanroom production capability

- Medical or PPE project experience

- In-house mold design and tooling

- Quality system (ISO, FDA, CE support)

- Engineering support and DFM capability

- Flexible MOQ for prototype and pilot production

A reliable manufacturer helps reduce development risk and shorten time to market.

8. Common Challenges in Customizing Silicone Gas Mask Respirators

Some common technical challenges include:

- Achieving consistent face sealing across different face shapes

- Avoiding flash and air bubbles in LSR molding

- Ensuring valve reliability and airflow performance

- Balancing softness and structural support

- Meeting strict regulatory standards

Partnering with an experienced LSR factory can help solve these issues during the prototyping stage.

9. From Prototype to Mass Production: Typical Timeline

A standard customization timeline:

- Design review & DFM: 1–2 weeks

- Mold design & tooling: 3–6 weeks

- Prototype sampling: 1–2 weeks

- Testing & iteration: 2–4 weeks

- Mass production: 2–4 weeks

Total development cycle: approximately 2–3 months depending on complexity.

10. Conclusion: Launch Your Custom Silicone Rubber Gas Mask with Confidence

Custom silicone rubber gas mask respirators offer superior comfort, sealing performance, and durability compared to traditional materials. With the right LSR injection molding partner, brands can efficiently transform design concepts into certified, mass-produced PPE products.

From material selection and mold design to injection molding and quality control, every step plays a critical role in product success. Choosing an experienced silicone respirator manufacturer not only ensures product quality but also accelerates your time to market and enhances your brand competitiveness in the PPE industry.