Table of Contents

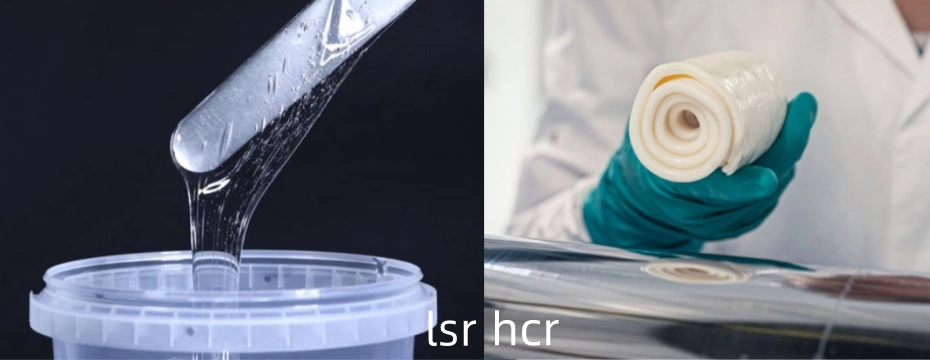

ToggleLiquid Silicone Rubber (LSR) and traditional rubber are widely used in industries such as healthcare, food packaging, automotive, and consumer electronics. One of the growing demands from manufacturers and end-users is the ability to customize these materials with different colors for functionality, branding, and aesthetics. Coloring LSR and rubber products requires professional material knowledge, suitable pigments, and controlled processing techniques.

In this article, we will explore how to make LSR and rubber products in color, the methods used, the challenges manufacturers face, and the benefits for different industries.

1. Understanding LSR and Rubber Products

1.1 What is LSR?

Liquid Silicone Rubber (LSR) is a two-component, platinum-cured material processed by injection molding. It offers outstanding properties such as:

- High thermal stability

- Biocompatibility (suitable for medical applications)

- Flexibility and elasticity

- Transparency (ideal for coloring)

- Chemical resistance

1.2 What is Rubber?

Rubber, whether natural or synthetic (EPDM, NBR, SBR, etc.), is processed through compression, transfer, or injection molding. It is known for:

- Durability and toughness

- Wide hardness range

- Good sealing and insulation properties

- Compatibility with industrial applications

Both LSR and rubber can be customized in color, but the methods and pigments differ due to material chemistry.

2. Why Color LSR and Rubber Products?

Coloring is not only for appearance but also serves functional and branding purposes:

- Brand Identity: Companies use colors to differentiate their products.

- Functionality: Color coding helps in medical devices, cables, and industrial seals.

- User Experience: Colored silicone baby products, kitchenware, and wearables are more attractive to consumers.

- Safety Compliance: Certain industries require color-specific markings for safety standards.

3. Methods of Coloring LSR Products

LSR is naturally translucent, making it ideal for vibrant coloring. Common methods include:

3.1 Pre-Colored LSR Compounds

- Pigments are mixed by the material supplier before delivery.

- Ensures consistency and stability.

- Best for high-volume production with fixed color requirements.

3.2 Liquid Color Pigments

- Added during the injection molding process using a dosing system.

- Flexible for custom orders and low-volume production.

- Allows precise color adjustment.

3.3 Masterbatch Pigments

- Solid silicone-based color masterbatches are mixed with raw LSR.

- Good balance between cost and flexibility.

Unlike LSR, rubber coloring is slightly more complex due to the material’s opacity and curing process.

4.1 Dry Pigments

- Powders mixed into raw rubber before processing.

- Widely used but may cause dispersion challenges.

4.2 Pre-Dispersed Pigments (Masterbatch)

- Pigments pre-mixed with a carrier rubber compound.

- Offers uniform color distribution and improved quality.

4.3 Coating or Surface Coloring

- Post-molding painting or coating.

- Suitable for decorative or secondary color finishes.

5. Challenges in Coloring LSR and Rubber Products

While coloring offers benefits, manufacturers face several technical challenges:

- Color Consistency: Maintaining the same shade in large production batches.

- Heat Stability: Pigments must withstand high curing temperatures.

- Material Compatibility: Certain pigments may affect curing speed or mechanical properties.

- Regulatory Compliance: Medical-grade and food-grade products require FDA or ISO-approved pigments.

6. Applications of Colored LSR and Rubber Products

Color customization plays a crucial role in different industries:

- Medical Devices: Catheters, masks, and nasal cannulas use color coding for safety.

- Food & Kitchenware: Baby bottles, pacifiers, and silicone baking tools use bright, safe pigments.

- Consumer Electronics: Silicone keypads, gaskets, and wearable straps in customized brand colors.

- Automotive: Seals, grommets, and buttons in specific colors for identification.

- Industrial Products: Hoses, tubing, and sealing products with functional color codes.

7. Steps to Do LSR and Rubber Products in Color

If you are a manufacturer or sourcing partner, follow these steps:

- Define Requirements – Decide the purpose of coloring (aesthetic, branding, or functional).

- Choose Pigment Type – Based on material (liquid pigments for LSR, masterbatch for rubber).

- Check Regulations – Ensure pigments meet FDA, RoHS, or medical standards if applicable.

- Test Compatibility – Evaluate color stability under curing and application conditions.

- Process Optimization – Adjust injection or compression molding parameters for uniform color.

- Quality Control – Use spectrophotometers to check color consistency.

8. Benefits of Colored LSR and Rubber Products

- Enhanced product appeal and market competitiveness

- Improved safety and usability in regulated industries

- Better brand recognition with custom colors

- Flexibility in design and product differentiation

With advancements in materials science, new opportunities are emerging:

- Eco-Friendly Pigments: Bio-based and non-toxic pigments for sustainable production.

- Smart Coloring: Thermochromic and photochromic pigments that change color under conditions.

- Digital Color Matching: AI-driven color control for precise production consistency.

Conclusion

Coloring LSR and rubber products is not just about aesthetics—it improves functionality, safety, and brand identity. By selecting the right pigments, following proper processing methods, and ensuring compliance with industry standards, manufacturers can produce high-quality, durable, and visually appealing products.

As industries demand more customization and innovation, the ability to produce colored LSR and rubber products will continue to be a valuable capability for manufacturers worldwide.