Table of Contents

ToggleSilicone rubber face masks have become increasingly popular in cosmetic, skincare, and medical applications due to their flexibility, skin safety, durability, and excellent sealing performance. Whether used for cosmetic sheet mask carriers, reusable silicone facial masks, or medical facial coverings, high-quality silicone face masks all start with a precisely designed mold.

In this guide, we will explain how to do a silicone rubber face mask mold, covering everything from material selection and mold design to manufacturing processes and quality control. This article is written from a professional silicone molding factory perspective, making it especially useful for buyers, product developers, and engineers.

1. What Is a Silicone Rubber Face Mask Mold?

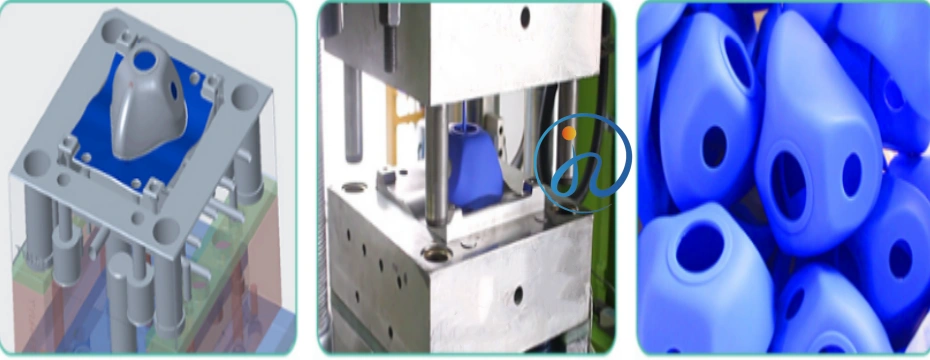

A silicone rubber face mask mold is a custom-designed mold used to produce silicone face masks through processes: liquid silicone rubber (LSR) injection molding.

The mold determines:

- Facial contour accuracy

- Thickness uniformity

- Edge sealing performance

- Surface texture and finish

Because face masks come into direct contact with human skin, the mold must support medical-grade or food-grade silicone, high precision, and consistent repeatability.

2. Choosing the Right Silicone Material

Before designing the mold, selecting the correct silicone rubber is critical.

Common Silicone Materials Used

Liquid Silicone Rubber (LSR)

- Ideal for high-precision face mask molds

- Excellent flowability

- Suitable for complex facial contours

- Medical-grade options available

- Automated mass production

3. Silicone Face Mask Mold Design Considerations

Mold design is the most critical step in making a successful silicone rubber face mask.

3.1 Facial Ergonomics & Fit

The mold cavity must match:

- Human facial anatomy

- Eye, nose, and mouth positioning

- Cheekbone and jawline curves

Many manufacturers use:

- 3D face scanning data

- Anthropometric databases

- Customized customer CAD files

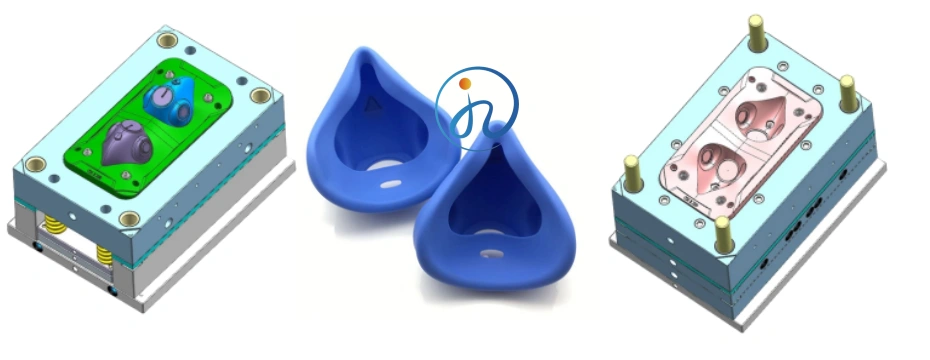

3.2 Mold Cavity Structure

Common designs include:

- Single-cavity mold (for sampling or low volume)

- Multi-cavity mold (for mass production)

Key factors:

- Uniform thickness (usually 1.5–3.0 mm)

- Smooth transitions to avoid stress points

- Rounded edges for comfort

3.3 Parting Line Design

- Avoid parting lines on sensitive facial areas

- Keep parting lines hidden at outer edges

- Ensure easy demolding without tearing

4. Mold Material Selection

The mold steel must withstand:

- High temperatures

- Continuous injection cycles

- Silicone abrasion resistance

Common Mold Steel Options

- Stainless steel S136 – excellent corrosion resistance for medical silicone

5. Mold Manufacturing Process

No 1: CAD & Mold Flow Analysis

- 3D modeling of the mold

- Silicone flow simulation

- Gate position optimization

- Air trap and venting analysis

Step 2: CNC Machining

- High-precision CNC milling

- Mirror-finish cavity machining

- Tolerance control within ±0.01 mm

3: EDM (Electrical Discharge Machining)

- Used for complex facial details

- Ensures fine texture and depth accuracy

Step 4: Polishing & Surface Treatment

- Mirror polish for cosmetic masks

- Matte or skin-like texture if required

- Surface roughness control (Ra ≤ 0.2 μm)

6. LSR Injection Molding Process for Face Masks

6.1 Material Preparation

- Two-part LSR (A+B)

- Precise 1:1 mixing

- Automatic dosing system

6.2 Injection Molding

- Cold runner system

- Controlled injection pressure

- Mold temperature: 160–200°C

- Short curing time (30–60 seconds)

6.3 Demolding

- Automatic demolding preferred

- No mold release required

- Minimal flash if mold is well designed

7. Venting and Runner System Design

Venting

- Crucial for thin face mask parts

- Prevents air bubbles and burn marks

- Vent depth usually 0.01–0.02 mm

Runner System

- Cold runner system reduces material waste

- Balanced runner layout ensures even filling

- Valve gates for high-end applications

8. Quality Control for Silicone Face Mask Molds

Mold Inspection

- Cavity dimension measurement

- Surface finish inspection

- Parting line accuracy

Product Testing

- Thickness consistency

- Tear strength testing

- Skin contact safety verification

- Visual inspection for bubbles or flow marks

Certifications

- FDA

- LFGB

- ISO 10993

- REACH / RoHS (for EU market)

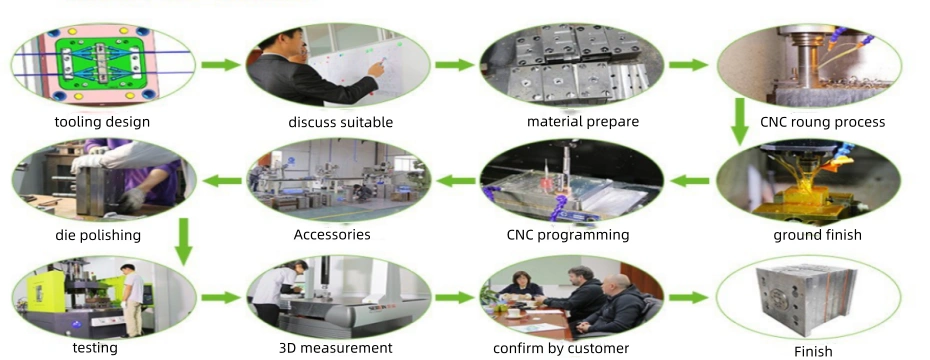

9. Custom Silicone Face Mask Mold Development Process

A professional factory usually follows this workflow:

- Customer concept or drawing

- DFM (Design for Manufacturability) review

- Mold design & confirmation

- Tooling fabrication

- Sample testing (T0 / T1)

- Mold modification if needed

- Mass production approval

This process ensures stable quality and cost efficiency.

10. Why Choose a Professional Silicone Mold Manufacturer?

A reliable silicone mold supplier offers:

- In-house mold design

- Medical-grade silicone sourcing

- Advanced LSR injection machines

- Strict quality control

- Confidentiality protection (NDA)

This is especially important for cosmetic brands and medical device companies.

11. Conclusion

Making a high-quality silicone rubber face mask mold requires more than basic tooling knowledge. It involves material science, ergonomic design, precision machining, and controlled molding processes.

By choosing the right silicone material, optimizing mold design, and working with an experienced LSR molding manufacturer, you can achieve:

- Comfortable facial fit

- Consistent product quality

- Scalable mass production

- Compliance with international standards

If you are planning to develop or customize silicone face masks, investing in a professional silicone rubber mold is the foundation of success.