Table of Contents

ToggleA baby pacifier is more than just a comfort item—it’s a critical baby care product that must meet the highest standards of safety, durability, and hygiene. Among various materials, liquid silicone rubber (LSR) has become the top choice for manufacturing baby pacifiers due to its excellent biocompatibility and heat resistance. In this article, we’ll walk through the complete process of how to make a silicone baby pacifier, from selecting raw materials to final packaging.

Whether you’re a product designer, procurement officer, or curious parent, this guide provides in-depth insights into every aspect of baby pacifier manufacturing.

1. Why Choose Silicone for Baby Pacifiers?

a. Medical-Grade Safety

Silicone used in baby pacifiers is typically medical-grade LSR—it is non-toxic, hypoallergenic, and BPA-free. It doesn’t leach chemicals, making it ideal for infants who are prone to placing items in their mouths.

b. Heat and UV Resistance

Silicone can withstand boiling, sterilization, and UV light, which ensures the pacifier remains clean and durable over time.

c. Soft Yet Durable

The elasticity and softness of LSR provide comfort during teething while being strong enough to resist tearing or cracking.

2. Material Selection: What Silicone Is Used?

The preferred material is Liquid Silicone Rubber (LSR) because of its:

- Biocompatibility: Safe for extended contact with the skin and mucous membranes.

- Transparency: Allows for visual inspection of cleanliness.

- Moldability: Excellent flowability for complex shapes and overmolding.

Additional certifications for silicone used in baby pacifiers:

- FDA 21 CFR 177.2600

- ISO 10993 (Biocompatibility)

- LFGB (for European markets)

3. Designing a Baby Pacifier

A functional and safe baby pacifier design typically includes:

- Nipple: Soft and shaped for sucking (orthodontic or rounded)

- Shield: Prevents the entire pacifier from entering the baby’s mouth

- Ventilation holes: Allow airflow and prevent skin irritation

- Handle: For safe removal by parents

Designs must comply with standards like EN 1400 (Europe) or ASTM F963 (USA) for infant product safety.

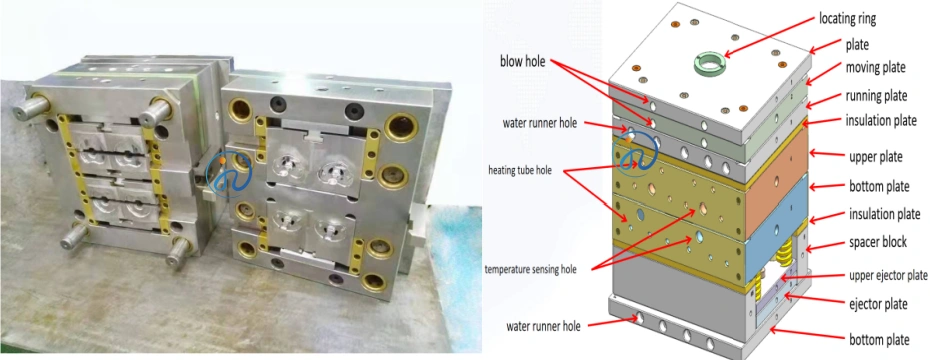

4. Tooling and Mold Design

High-precision steel molds are required for LSR injection molding. Key considerations:

- Number of cavities: Determines output per cycle

- Mold surface texture: Affects the final appearance and grip

- Cold-runner system: Common in LSR molds to prevent waste

For baby pacifiers, two-shot molding is often used to combine different silicone hardness levels or to overmold a handle or ring.

5. LSR Injection Molding Process

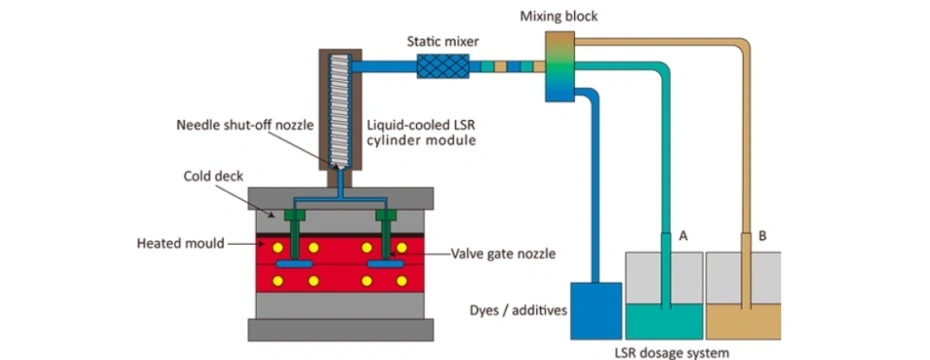

This is the core step in silicone baby pacifier manufacturing:

a. Material Preparation

LSR comes in two parts (A & B) stored in drums. Pigments can be added for color.

b. Metering & Mixing

A dosing system mixes the A & B components with pigment in exact ratios.

c. Injection

- Mixed LSR is injected into a closed mold under pressure.

- Curing occurs inside the mold at ~150–180°C for 30–90 seconds.

d. Demolding

- Pacifiers are automatically ejected or manually removed.

- Flash trimming may be done if needed.

6. Post-Molding Processing

a. Flash Trimming

Any excess material (flash) around the mold seam is removed either manually or with cryogenic deflashing.

b. Surface Treatment

Some products undergo surface treatment (e.g., plasma coating) to reduce dust attraction or increase silky feel.

c. Sterilization

Pacifiers are sterilized using:

- Autoclaving

- UV treatment

- Gamma radiation (for hospital-grade models)

7. Quality Control and Safety Testing

Baby pacifiers must pass strict QC tests:

- Tensile strength of nipple and shield

- Bite and tear resistance

- Drop test to ensure durability

- Migration testing for chemicals

- Sterility testing

Manufacturers often follow ISO 9001 and ISO 13485 quality systems for consistent production standards.

8. Branding and Customization

Many baby product brands request custom designs, colors, or logos. Customization options include:

- Silicone color matching (food-safe pigments)

- Embossed or printed logos

- Unique shape design

- Glow-in-the-dark or temperature-sensitive features

9. Assembly and Packaging

Some pacifier models have detachable rings or caps. Assembly includes:

- Joining different molded parts (using LSR-to-LSR bonding or mechanical joining)

- Quality inspection for final product

- Packing in sterile, tamper-proof blister packs or boxes

Packaging should be labeled with:

- Age range (e.g., 0–6 months)

- Safety instructions

- Sterilization guidelines

10. Compliance and Export Requirements

To sell baby pacifiers globally, manufacturers must ensure compliance with:

- FDA 510(k) clearance (if marketed as a medical device)

- CE marking for EU markets

- CPC certificate for US consumer goods

- National labeling and warning requirements

Conclusion

Making a silicone baby pacifier involves much more than molding rubber into shape—it requires strict material selection, precision manufacturing, and rigorous quality control to ensure infant safety. By following international standards and using high-quality liquid silicone rubber, manufacturers can produce pacifiers that parents trust and babies love.

For OEM/ODM pacifier manufacturing, choosing a professional LSR injection molding partner ensures product quality, compliance, and long-term success in the baby care market.