Table of Contents

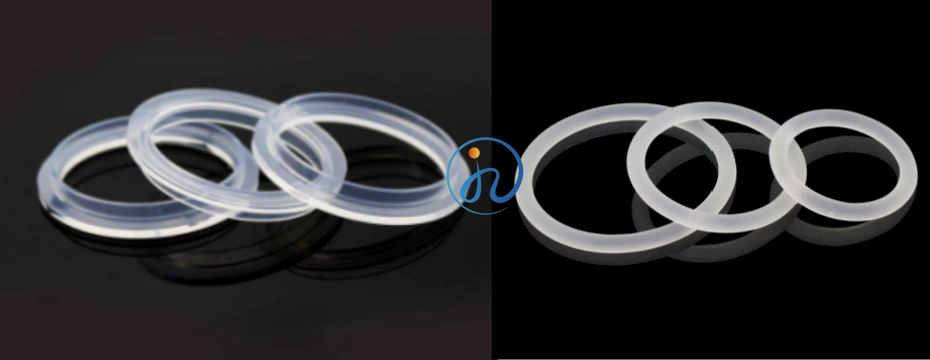

ToggleMedical silicone sealing rings are critical components used in a wide range of healthcare and medical devices, including respirators, medical masks, infusion systems, diagnostic equipment, and fluid control assemblies. Their primary function is to provide reliable, leak-proof sealing while maintaining biocompatibility, flexibility, and durability under strict medical conditions.

Due to increasing regulatory requirements and higher expectations for safety and performance, most medical device manufacturers now rely on medical-grade liquid silicone rubber (LSR) to produce sealing rings.

What Is a Medical Silicone Sealing Ring?

A medical silicone sealing ring is a precision elastomeric gasket designed to prevent the leakage of gases or liquids in medical applications. Unlike industrial sealing rings, medical sealing rings must meet strict biocompatibility and cleanliness standards.

Common applications include:

- Medical mask and respirator sealing systems

- Oxygen and anesthesia equipment

- Infusion pumps and IV connectors

- Diagnostic and laboratory instruments

- Drug delivery devices

These sealing rings typically come into direct contact with skin, airways, fluids, or drugs, making material choice and manufacturing quality essential.

Why Liquid Silicone Rubber (LSR) Is Used for Medical Sealing Rings

Liquid silicone rubber is the preferred material for medical sealing rings because of its unique properties:

- Excellent biocompatibility (ISO 10993, USP Class VI)

- Soft, elastic, and durable

- Resistant to heat, chemicals, and sterilization

- Odorless, tasteless, and non-toxic

- Stable performance over long service life

Compared with TPE, rubber, or PVC, medical-grade LSR offers superior sealing reliability and patient safety.

Step 1: Selecting the Right Medical-Grade Silicone Material

Medical-Grade LSR Requirements

The first step in making medical silicone sealing rings is selecting the correct medical-grade liquid silicone rubber, which must comply with global regulations.

Key material requirements include:

- Platinum-cured LSR (not peroxide-cured)

- FDA 21 CFR compliance

- ISO 10993 biological evaluation

- USP Class VI certification

- Low volatile and extractable content

Shore Hardness Selection

The hardness of the silicone sealing ring affects sealing performance and durability.

Common hardness ranges:

- Shore A 20–30: Ultra-soft, skin-contact seals

- Shore A 30–40: Respirator and mask sealing rings

- Shore A 40–60: Fluid and gas sealing applications

Proper hardness selection ensures airtight sealing without excessive compression force.

Step 2: Designing the Medical Silicone Sealing Ring

Functional Design Considerations

Medical sealing ring design must balance:

- Sealing efficiency

- Compression behavior

- Long-term elastic recovery

- Ease of assembly

Key design factors include:

- Cross-section shape (O-ring, D-ring, custom profile)

- Compression ratio (typically 15–30%)

- Surface contact area

- Tolerance requirements

CAD and Engineering Validation

Designs are usually created using CAD software and validated through:

- Finite Element Analysis (FEA)

- Compression and fatigue simulations

- Prototype testing

Accurate design reduces leakage risk and ensures consistent performance.

Step 3: Medical-Grade LSR Mold Design

Mold Structure for Silicone Sealing Rings

LSR molds differ significantly from traditional plastic molds. Key features include:

- Cold runner or valve gate system

- High-precision cavity machining

- Excellent venting for air release

- Polished mold surfaces

Medical sealing rings often require multi-cavity molds for high-volume production.

Gate and Parting Line Design

For medical applications:

- Gate marks must be minimal or invisible

- Parting lines must not affect sealing surfaces

- Flash must be strictly controlled

Precision mold design directly impacts sealing quality and product consistency.

Step 4: LSR Injection Molding Process

What Is LSR Injection Molding?

LSR injection molding is a fully automated, closed-system process where two liquid silicone components are mixed, injected, and cured inside a heated mold.

Key Process Steps

- Metering and mixing of LSR components

- Injection into heated mold cavity

- Rapid curing (vulcanization)

- Demolding and automatic part removal

Typical molding temperature ranges from 160°C to 200°C, with short cycle times.

Advantages for Medical Sealing Rings

- High dimensional accuracy

- Repeatable quality

- Minimal contamination risk

- Low scrap rate

LSR injection molding is ideal for medical sealing rings requiring tight tolerances and high cleanliness.

Step 5: Demolding and Post-Processing

Automatic Demolding

Medical silicone sealing rings are often demolded using:

- Automatic ejectors

- Robotic handling

- Vacuum pick-and-place systems

This reduces human contact and contamination risk.

Post-Curing (If Required)

Some medical applications require post-curing to:

- Remove volatile residues

- Improve mechanical stability

- Meet regulatory requirements

Post-curing is typically done in a controlled oven environment.

Step 6: Quality Control and Inspection

Dimensional and Visual Inspection

Every batch of medical silicone sealing rings undergoes:

- Dimensional measurement

- Visual inspection for flash, bubbles, or defects

- Surface finish evaluation

Functional Testing

Common tests include:

- Compression set testing

- Leak and pressure testing

- Tensile and tear strength testing

- Aging and fatigue testing

Cleanroom Manufacturing (Optional)

High-risk medical sealing rings are often produced in:

- ISO Class 7 or Class 8 cleanrooms

Cleanroom production ensures compliance with medical device standards.

Common Medical Applications of Silicone Sealing Rings

Medical silicone sealing rings are used in:

- Medical mask and respirator systems

- Ventilators and oxygen equipment

- Infusion and dialysis devices

- Diagnostic instruments

- Drug delivery systems

Their reliability directly impacts patient safety and device performance.

LSR vs Other Materials for Medical Sealing Rings

| Property | LSR | TPE | Rubber | PVC |

|---|---|---|---|---|

| Biocompatibility | Excellent | Good | Limited | Moderate |

| Sterilization Resistance | Excellent | Limited | Poor | Poor |

| Compression Set | Low | Medium | High | High |

| Odor/Taste | None | Slight | Possible | Noticeable |

| Service Life | Long | Medium | Short | Short |

LSR clearly outperforms alternative materials in medical sealing applications.

Why Choose an Experienced Medical LSR Manufacturer

Producing medical silicone sealing rings requires:

- Deep material knowledge

- Precision mold engineering

- Strict quality control

- Medical regulatory experience

An experienced LSR manufacturer can:

- Optimize design for sealing performance

- Reduce approval and validation time

- Ensure consistent mass production

Conclusion

Manufacturing medical silicone sealing rings is a high-precision, regulated process that demands the right material, advanced mold design, and strict quality control. By using medical-grade liquid silicone rubber and LSR injection molding, manufacturers can produce sealing rings that meet the highest standards of safety, durability, and performance.

For medical devices where leak prevention, patient safety, and long-term reliability are critical, silicone sealing rings made from LSR remain the gold standard.