Table of Contents

ToggleIn the precision world of LSR (Liquid Silicone Rubber) injection molding, the steel mold is the foundation of quality. Companies that want to be long-term, trusted partners in mold manufacturing must not only offer technical excellence but also deliver reliability, consistency, and open collaboration.

This guide will show you how to become a strategic partner in manufacturing a steel mold for LSR injection molding, covering every step—from design to delivery—and what clients expect when they choose a mold manufacturing partner.

1. Why Steel Molds Are Essential for LSR Injection Molding

A steel mold is at the core of any LSR injection molding process. Unlike thermoplastics, LSR is a two-component liquid material that requires:

- High-temperature curing (160°C–220°C)

- Tight sealing due to low viscosity

- Accurate venting to avoid air traps

- Flash control due to the material’s flow characteristics

Only hardened, precision-machined steel molds can consistently meet the mechanical and dimensional requirements of industries like medical, baby care, automotive, and electronics.

2. Understand the Role of a Mold Manufacturing Partner

As a mold manufacturer, you’re not just delivering tooling—you are delivering production success. Your responsibilities include:

- Collaborating during product development

- Offering design-for-manufacturability (DFM) input

- Ensuring durability and dimensional accuracy

- Providing fast lead times and responsive communication

- Supporting modifications and long-term maintenance

Being a great partner means adding value beyond the mold itself.

3. Begin with Application & Product Understanding

Before quoting or designing a steel mold, start by understanding:

- The end-use application (medical, automotive, food-grade, etc.)

- Required part tolerances

- LSR material specifications (Shore hardness, cure behavior)

- Mold cavity count, shot volume, and cycle time goals

The more aligned you are with your client’s needs, the better the outcome.

4. Offer Design for Manufacturability (DFM) Support

Top-tier mold partners actively provide DFM feedback. Key points include:

- Draft angles and parting line location

- Undercuts that require side actions

- Gate location and cold runner design

- Venting placement to avoid air traps

- Tolerancing for LSR shrinkage (~2-4%)

Using mold flow simulation tools like Moldex3D or Sigmasoft can enhance your proposals and win client trust.

5. Choose the Right Steel Material for Mold Making

Choosing the correct steel is critical for performance and longevity. Common options include:

| Steel Type | Characteristics | Applications |

|---|---|---|

| S136 | Pre-hardened stainless steel, corrosion-resistant | Medical or food-grade LSR tools |

| H13 | Tool steel, excellent for high heat and abrasion | Automotive and industrial molds |

| 420SS | Corrosion-resistant, good for polished surfaces | Baby care and consumer products |

Proper heat treatment of the steel ensures hardness (HRC 45–52) and stability.

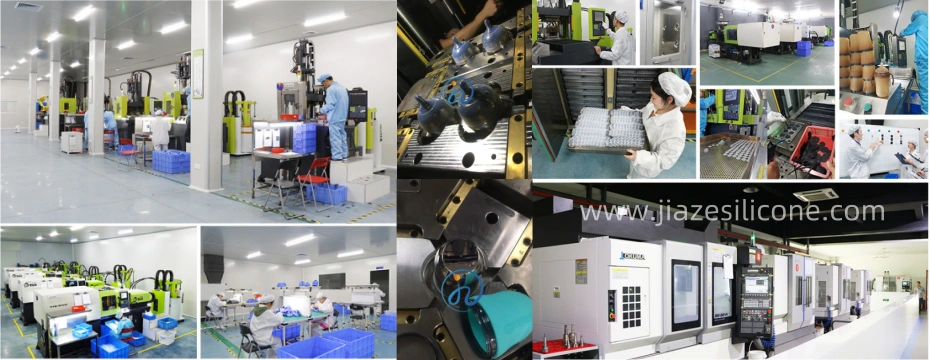

6. Use High-Precision Machining Equipment

To be a high-level partner, invest in:

- 3-axis and 5-axis CNC machining for complex geometries

- EDM (Electrical Discharge Machining) for tight corners and ejector holes

- High-speed milling for core and cavity

- Coordinate Measuring Machines (CMM) for inspection

- Surface polishing & texturing for flash-free silicone parts

Precision tolerance is often ±0.01mm or better for LSR mold inserts.

7. Incorporate Key Mold Features

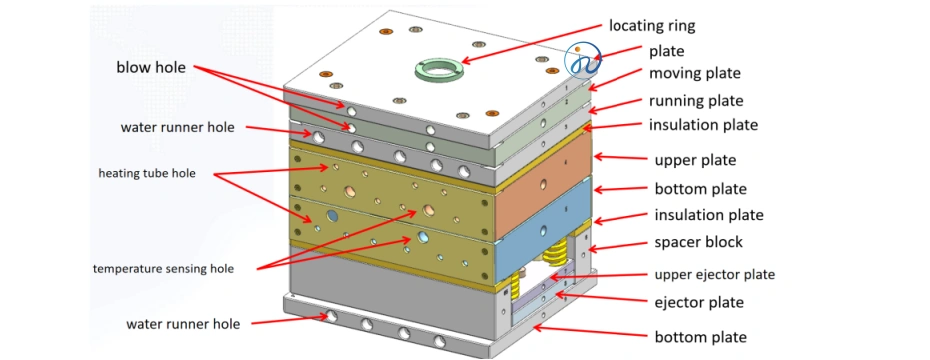

A functional LSR steel mold should include:

- Cold runner system to prevent premature curing

- Valve or pinpoint gate designs for clean injection

- Venting grooves or vacuum channels to remove trapped air

- Polished parting lines to prevent flash

- Efficient mold cooling and heating systems for cycle time optimization

Also ensure easy disassembly for maintenance and insert replacement.

8. Conduct Mold Assembly, Testing, and T0 Trial

Before shipping, responsible partners perform:

- Full mold assembly and fitting

- Dry cycling to check alignment and sealing

- T0 mold trial using actual LSR material

- Measurement of first samples for dimensional accuracy

- Adjustments as needed before final shipment

Provide a mold test report, including part dimensions, flash level, curing time, and gate balance.

9. Provide Technical Documentation & Support

As a manufacturing partner, you must deliver:

- 3D mold design files (STEP/IGES format)

- 2D drawings of critical components

- Material certifications for the steel used

- Maintenance instructions and spare part list

- Ongoing support for future mold revisions or spare inserts

Responsive after-sales support is what distinguishes a supplier from a true partner.

10. Be Transparent in Pricing and Timelines

Clients appreciate partners who are:

- Clear on cost breakdowns: mold base, inserts, sliders, hot/cold runner, etc.

- Upfront about lead times: typically 3–6 weeks depending on complexity

- Flexible with change requests or urgent delivery schedules

- Able to offer value-added options like mold storage, repair services, or multi-location shipping

Building trust through transparency leads to long-term cooperation.

11. Achieve Certifications and Industry Standards

Depending on your client’s sector, having the following certifications will increase credibility:

- ISO 9001 – General quality management

- ISO 13485 – Medical devices

- IATF 16949 – Automotive production

- RoHS / REACH compliance – Material safety

- FDA material approval – For food and baby care molds

These certifications show you’re capable of global cooperation.

12. Build Long-Term Collaborative Relationships

Being a steel mold manufacturer is not a one-time transaction. It’s about forming partnerships that grow with:

- Product lifecycle development

- Mold maintenance and upgrades

- Volume production support

- Technical consulting for new products

Consistent delivery + proactive service = long-term partnership.

Conclusion: Be More Than a Mold Maker – Be a Partner

To be a successful partner in manufacturing a steel mold for LSR injection molding, you must combine:

- Engineering precision

- Strong communication

- Transparent pricing

- On-time delivery

- Reliable after-sales service

Customers are not just looking for a tool—they’re looking for a trusted team that supports their product success from prototyping to mass production.

If you’re ready to build that kind of partnership, ensure your mold shop operates with the precision, passion, and professionalism the LSR industry demands.