Table of Contents

ToggleLiquid Silicone Rubber (LSR) manufacturing has become a core production method for high-precision, high-performance silicone components across industries such as medical devices, automotive, electronics, baby care, and wearable products.

If you are a product designer, sourcing manager, or startup founder, understanding how LSR parts are manufactured helps you optimize product design, control costs, and shorten time to market. This guide walks you through the complete LSR manufacturing process, from material selection to mass production.

1. What Is Liquid Silicone Rubber (LSR)?

Liquid Silicone Rubber is a two-part platinum-cured elastomer that is injection molded in a closed system. Unlike traditional solid silicone rubber (HTV), LSR is delivered in liquid form and processed through automated injection molding equipment.

Key properties of LSR:

- High elasticity and tear resistance

- Excellent temperature stability (-60°C to 200°C)

- Biocompatibility (medical-grade options)

- Chemical resistance

- Transparency (optical-grade available)

- Long service life and durability

These properties make LSR ideal for:

- Medical seals, masks, valves

- Respirator face masks

- Automotive connectors

- Waterproof gaskets

- Baby feeding products

- Consumer electronics keypads

2. Typical Applications of LSR Parts

LSR is widely used in applications requiring precision, cleanliness, and high-volume consistency:

- Medical & Healthcare: masks, tubing connectors, diaphragms, seals

- Automotive: O-rings, gaskets, vibration dampers

- Consumer Products: wearable device seals, kitchenware components

- Electronics: waterproof housings, membrane switches

- Industrial: fluid control components

Understanding the application helps define material grade, mold structure, and production parameters.

3. Step-by-Step Process to Manufacture LSR Parts

3.1 Product Design & DFM Analysis

Before manufacturing begins, product design must be optimized for LSR injection molding. A professional manufacturer will provide Design for Manufacturability (DFM) feedback, including:

- Wall thickness optimization (typically 0.8–3.0 mm)

- Undercut and draft angle evaluation

- Gate location planning

- Parting line and flash control design

- Tolerance evaluation

3.2 LSR Material Selection

Choosing the right LSR material is critical. Common selection factors include:

- Hardness (Shore A 10–80)

- Medical-grade or food-grade compliance (FDA, ISO 10993)

- Optical transparency

- Chemical resistance

- Tear strength

- Colorability

Suppliers typically provide customized LSR compounds for specific industries. A professional manufacturer assists in selecting the best-fit grade.

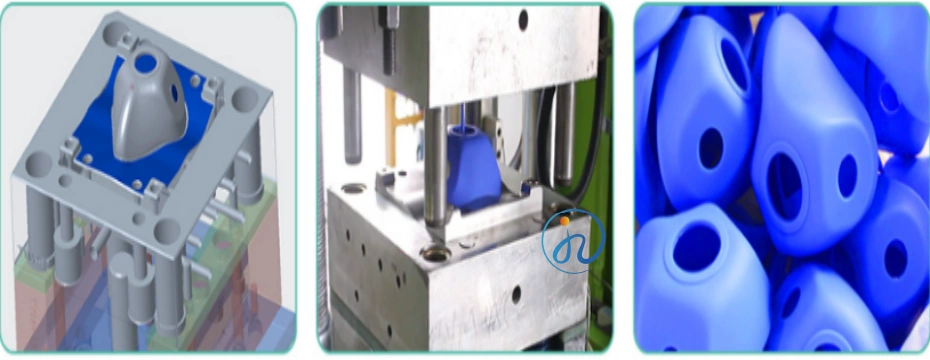

3.3 LSR Injection Mold Design

LSR molds differ from traditional plastic molds. Key features include:

- Cold runner system to prevent premature curing

- Precision temperature control (mold heated, barrel cooled)

- Vacuum system to eliminate air traps

- High-polish cavity for medical or optical parts

- Flash-free mold structure

High-quality mold design directly impacts:

- Part appearance

- Dimensional accuracy

- Tool lifespan

- Production efficiency

3.3 LSR Injection Mold Design

LSR molds differ from traditional plastic molds. Key features include:

- Cold runner system to prevent premature curing

- Precision temperature control (mold heated, barrel cooled)

- Vacuum system to eliminate air traps

- High-polish cavity for medical or optical parts

- Flash-free mold structure

High-quality mold design directly impacts:

- Part appearance

- Dimensional accuracy

- Tool lifespan

- Production efficiency

3.4 LSR Injection Molding Process

The LSR injection molding process involves:

- Metering & Mixing: Two-part LSR material is precisely mixed (1:1 ratio).

- Injection: Material is injected into a heated mold cavity.

- Curing: Platinum-catalyzed crosslinking occurs inside the mold.

- Demolding: Finished elastic parts are ejected automatically.

- Post-Curing (if required): For medical or high-performance applications.

Typical advantages:

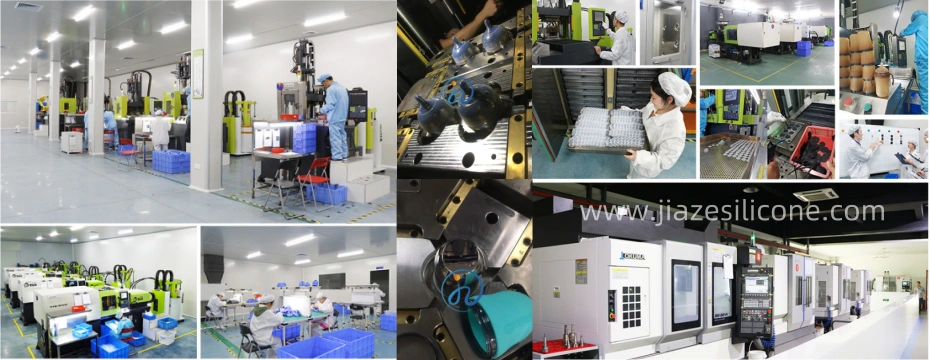

- Fully automated production

- No regrinding waste

- High repeatability

- Cleanroom compatible manufacturing

4. Secondary Processing & Assembly

After molding, some LSR parts require secondary processes:

- Deflashing (if micro-flash exists)

- Post-curing for volatile removal

- Bonding with plastic or metal (LSR overmolding)

- Surface treatment (plasma, coating)

- Assembly into final products

LSR overmolding with thermoplastics (like PC, PA, ABS) is increasingly popular in wearable devices and medical products.

5. Quality Control in LSR Manufacturing

Strict quality control ensures product reliability:

Common QC methods include:

- Incoming material inspection

- In-process dimensional checks

- Visual inspection for flash and defects

- Tensile strength and elongation testing

- Biocompatibility and compliance testing

- Leak and pressure testing (for seals and masks)

For medical or respirator components, ISO 13485 and GMP-compliant processes are recommended.

6. How to Reduce Manufacturing Cost of LSR Parts

Cost control is a key concern for buyers. Here are proven strategies:

- Optimize part design to reduce material usage

- Simplify mold structure

- Combine multi-cavity molds for high-volume production

- Choose suitable material grade (avoid over-specification)

- Plan for long-term production to amortize tooling cost

- Work with experienced LSR manufacturers to avoid trial-and-error costs

Early supplier involvement significantly lowers total project investment.

7. How to Choose the Right LSR Manufacturing Partner

A reliable LSR manufacturer should provide:

- In-house mold design & tooling

- DFM & engineering support

- Cleanroom production capability

- Medical-grade compliance experience

- Stable mass production capacity

- IP protection & NDA support

- Global export experience

A strong manufacturing partner turns your LSR design into scalable mass production efficiently and safely.

8. Future Trends in LSR Manufacturing

The LSR market is rapidly evolving with:

- Micro LSR molding for precision medical parts

- Multi-shot LSR overmolding

- Automation and smart factory integration

- Sustainable silicone material development

- Increased use in wearable and healthcare devices

Manufacturers investing in automation and digital quality control will gain long-term competitive advantages.

9. Conclusion

Manufacturing liquid silicone rubber parts is a highly specialized process that integrates material science, mold engineering, automation, and quality control. From design and material selection to mass production and post-processing, every step impacts the final product’s performance and cost.

By working with an experienced LSR injection molding manufacturer early in the development stage, you can:

Reduce development risk

Improve product reliability

Control production cost

Speed up time to market

If you are planning an LSR project, professional engineering support is the fastest path from concept to successful mass production.