Table of Contents

ToggleIn the world of high-performance products — especially in automotive, medical, baby care, and consumer electronics industries — LSR overmolding PC (Liquid Silicone Rubber over Polycarbonate) has become a preferred solution for creating durable, biocompatible, and functional components. But how exactly is the process of overmolding LSR onto PC carried out?

This article explains the full process of producing LSR overmolding PC parts, from material selection to mold design, injection parameters, bonding techniques, and quality control — with best practices for manufacturers and engineers alike.

What Is LSR Overmolding PC?

LSR overmolding PC refers to the process of molding liquid silicone rubber (LSR) directly onto a rigid polycarbonate (PC) substrate using a two-shot or insert injection molding process. This results in a single, integrated part that combines the strength and structure of PC with the softness, flexibility, and sealing properties of silicone.

Common Applications:

- Medical devices (valves, masks, seals)

- Baby products (pacifiers, feeding nipples)

- Automotive components (switch covers, gaskets)

- Electronics (wearables, grips, seals)

Why Choose LSR Overmolding on PC?

1. Excellent Bonding Performance

Properly executed LSR overmolding creates a strong chemical and/or mechanical bond between PC and LSR, eliminating the need for adhesives.

2. Design Flexibility

This method allows combining rigid and soft elements in a single product, improving usability, aesthetics, and ergonomics.

3. Durability and Biocompatibility

LSR is heat-resistant, non-toxic, and highly durable, making it ideal for demanding applications.

4. Efficient Production

Multi-shot molding reduces assembly steps, lowers labor costs, and improves product consistency.

Step-by-Step: How to Produce LSR Overmolding PC

Step 1: Material Selection

Choosing the Right LSR:

- Medical-grade or food-grade LSR for healthcare/baby use

- Shore A hardness typically between 20A–70A depending on the application

- Consider self-adhesive LSR grades for PC substrates

Choosing the Right PC:

- Optical-grade PC for clarity

- Heat-resistant PC for higher processing temperatures

- Flame-retardant PC for electronics

Step 2: Surface Treatment of PC Substrate

Before overmolding, PC surface preparation is essential for strong adhesion.

- Plasma treatment or corona discharge can activate PC surface

- Chemical primers may be used to enhance bonding (if not using self-adhesive LSR)

- PC inserts must be clean, dry, and free of oils or contaminants

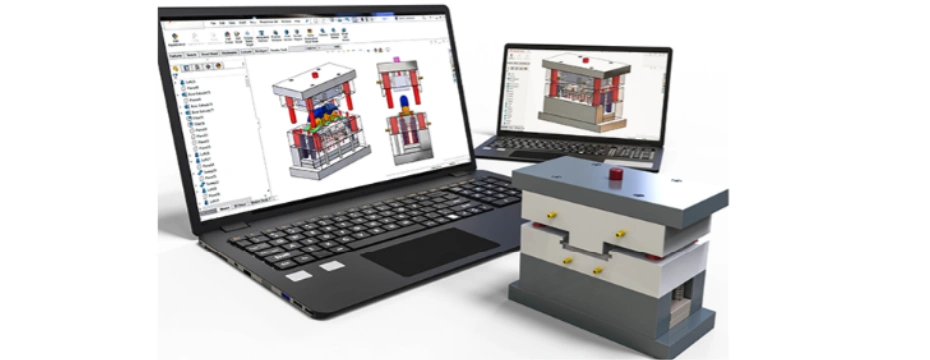

Step 3: Mold Design Considerations

2K Injection Mold (Two-Shot Tooling)

- One mold processes both PC and LSR in two sequential shots

- Rotating core or transfer plate is often used

Insert Molding

- PC part is pre-molded and manually or robotically inserted into the LSR mold

- Suitable for lower production volumes

Key Mold Design Tips:

- Venting is critical for LSR flow

- LSR shrinkage must be accounted for

- PC insert retention system must be precise to avoid misalignment

Step 4: Injection Molding Process

LSR Injection Settings:

- Low-viscosity LSR requires cold-runner systems

- Barrel temperatures: 20–30°C (cool)

- Mold temperatures: 160–200°C (hot)

- Injection pressure: medium to high

PC Injection Settings:

- PC must be injected first (higher temp ~280–320°C)

- Holding pressure and cooling times must be optimized

- Avoid thermal degradation of PC

Step 5: Bonding Techniques

To ensure long-lasting adhesion between LSR and PC, follow these bonding strategies:

- Self-adhesive LSR grades are preferred for automatic bonding without primers

- Surface pretreatments (plasma or UV-ozone) can enhance chemical bonding

- Mechanical interlocks in mold design add physical bonding support

Step 6: Quality Control and Testing

Perform thorough testing to ensure reliable production:

- Peel strength test to validate bond integrity

- Visual inspection for flash, bubbles, or bonding defects

- Dimensional inspection for tolerance control

- Thermal aging and chemical resistance tests for final applications

Best Practices for Producing LSR Overmolding PC Parts

Choose the Right Equipment:

- LSR metering and dosing units

- High-precision injection molding machines

- Robotic arms for insert placement (if applicable)

Optimize Cycle Time:

- Use hot molds with efficient cooling systems

- Avoid over-curing the LSR to save energy and time

Cleanroom Manufacturing:

- Especially important for medical and baby products

- Prevents contamination and ensures biocompatibility

Common Challenges in LSR Overmolding PC (and How to Avoid Them)

| Challenge | Solution |

|---|---|

| Poor adhesion | Use self-adhesive LSR, surface treatment, or bonding primer |

| Flash formation | Improve mold sealing and clamping |

| PC part deformation | Use correct temperature settings and cycle times |

| Air entrapment | Optimize mold venting and injection speed |

Future Trends in LSR Overmolding PC

- Advanced adhesion technologies (plasma + UV)

- Bio-based LSR materials for sustainability

- Miniaturization for electronics and wearable devices

- AI-driven process monitoring for smart manufacturing

Conclusion

Producing LSR overmolding PC components is a sophisticated process that demands precision in material handling, mold design, and processing techniques. When done correctly, it delivers unmatched product quality, bonding strength, and production efficiency.

Whether you’re manufacturing baby products, wearable tech, or medical seals, understanding the intricacies of LSR overmolding on PC can give your business a competitive edge in terms of innovation, performance, and cost-effectiveness.