Table of Contents

ToggleReusable silicone half mask respirators are widely used in industrial protection, medical environments, laboratories, and occupational safety applications. Compared with disposable respirators, silicone half masks offer better sealing performance, longer service life, improved comfort, and lower long-term cost.

For manufacturers and OEM buyers, understanding how to produce a reusable silicone half mask respirator is essential to ensure product quality, regulatory compliance, and market competitiveness.

What Is a Reusable Silicone Half Mask Respirator?

A reusable silicone half mask respirator is a face-mounted protective device that covers the nose and mouth, designed to work with replaceable filters or cartridges. It typically includes:

- Silicone face seal (main body)

- Filter connectors or valve housing

- Inhalation and exhalation valves

- Adjustable head straps

- Replaceable filter cartridges

Silicone is preferred because it offers excellent flexibility, skin safety, durability, and chemical resistance.

Why Silicone Is the Best Material for Half Mask Respirators

1. Excellent Sealing Performance

Silicone elastomers provide superior elasticity, allowing the mask to conform closely to different face shapes.

2. Skin-Friendly and Hypoallergenic

Medical-grade or high-purity silicone is non-toxic, odorless, and safe for long-term skin contact.

3. High Durability

Reusable silicone masks withstand repeated use, cleaning, and sterilization without deformation.

4. Chemical and Temperature Resistance

Silicone maintains stable performance under exposure to chemicals, oils, and temperature variations.

Step 1: Silicone Material Selection

Choosing the right silicone material is the foundation of respirator performance.

Liquid Silicone Rubber (LSR)

LSR is the most commonly used material for reusable half mask respirators.

Key advantages:

- High consistency and precision molding

- Excellent transparency or color stability

- Ideal for medical and PPE applications

- Suitable for automated mass production

Material Grades

- Medical-grade silicone (recommended for healthcare and PPE)

- Food-grade silicone (acceptable for general industrial use)

- Platinum-cured silicone (preferred for low VOC and odor-free requirements)

Key Material Properties to Consider

- Shore hardness (typically 30–50 Shore A)

- Tensile strength and elongation

- Tear resistance

- Biocompatibility (ISO 10993 if medical use)

Step 2: Product Design Considerations

Proper design ensures comfort, protection, and manufacturability.

Ergonomic Face Seal Design

- Anatomical contours for nose, cheeks, and chin

- Uniform wall thickness to avoid stress points

- Soft sealing lip for airtight fit

Filter Interface Design

- Standardized connector (e.g., bayonet or threaded)

- Secure locking mechanism

- Easy replacement of filters

Valve System Design

- One-way inhalation and exhalation valves

- Low breathing resistance

- Durable silicone or rubber valve membranes

Design for Manufacturability (DFM)

- Avoid sharp edges

- Optimize draft angles

- Minimize undercuts

- Design compatible with LSR injection molding

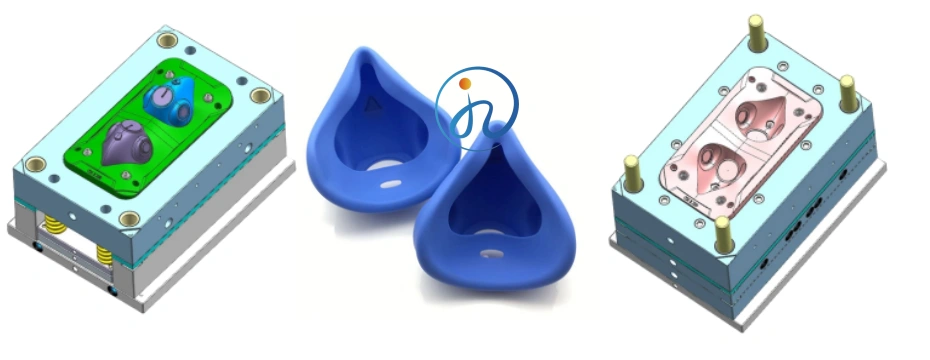

Step 3: Mold Design and Tooling

High-quality molds are critical for consistent respirator production.

LSR Injection Mold Features

- Cold runner system (preferred for silicone)

- Precision cavity machining

- Proper venting to eliminate air traps

- High-polish cavity surface for smooth finish

Multi-Cavity vs Single-Cavity Molds

- Single-cavity molds: Prototyping and low-volume production

- Multi-cavity molds: High-volume, cost-effective mass production

Mold Materials

- Hardened steel (S136)

- Corrosion-resistant coatings for long mold life

Step 4: Silicone Molding Process

Liquid Silicone Rubber Injection Molding

LSR injection molding is the most efficient and precise method for producing reusable silicone half mask respirators.

Process Steps

- Metering and mixing of two-part LSR

- Injection into heated mold cavity

- Vulcanization (curing) under controlled temperature

- Automatic demolding

- Flash inspection and trimming (if required)

Advantages

- High repeatability

- Minimal material waste

- Excellent dimensional accuracy

- Automation-friendly production

Alternative Processes (Less Common)

- Compression molding (for low volume)

- Transfer molding (limited complexity)

Step 5: Post-Processing and Assembly

After molding, additional steps are required.

Post-Curing (If Needed)

- Removes volatile residues

- Improves mechanical properties

- Required for medical-grade applications

Secondary Operations

- Valve installation

- Filter connector assembly

- Strap attachment

- Logo or marking (laser or pad printing)

Cleaning and Sterilization

- Ultrasonic cleaning

- Medical-grade washing processes

- Optional sterilization (ETO, steam, or UV depending on application)

Step 6: Quality Control and Testing

Strict quality control ensures user safety and regulatory compliance.

Incoming Material Inspection

- Material certification

- Batch traceability

In-Process Quality Checks

- Dimensional inspection

- Visual defect inspection

- Flash and surface quality check

Functional Testing

- Airtight sealing test

- Valve performance test

- Strap strength test

Performance Testing

- Fit test simulation

- Breathing resistance test

- Durability and fatigue test

Cost Factors in Producing Silicone Half Mask Respirators

Key cost drivers include:

- Silicone material grade

- Mold complexity and cavity number

- Production volume

- Labor and automation level

- Certification and testing costs

Mass production with LSR injection molding significantly reduces unit cost over time.

Conclusion

Producing a reusable silicone half mask respirator requires a combination of high-quality silicone materials, precise mold design, advanced LSR injection molding, strict quality control, and regulatory compliance.

For manufacturers and OEM buyers, partnering with an experienced silicone molding factory ensures reliable production, consistent quality, and faster time to market.

As demand for reusable protective equipment continues to grow, silicone half mask respirators remain a high-value, long-term product solution across medical, industrial, and safety markets.