Table of Contents

ToggleMedical LSR Project injection molding is widely used in medical devices, wearable healthcare products, respiratory masks, seals, diaphragms, and implantable components. Medical LSR offers excellent biocompatibility, chemical resistance, transparency, and durability.

However, many OEMs and medical startups hesitate to launch Medical LSR projects due to high upfront investment costs, including mold tooling, cleanroom production, validation, and regulatory compliance.

This article explains how to reduce the investment cost of medical LSR projects from product design, mold development, supplier selection, process optimization, and long-term production planning. These strategies help you control budget while ensuring medical-grade quality and compliance.

1. Understand Where the Main Costs Come From in Medical LSR Projects

Before reducing cost, you must understand the cost structure of medical LSR injection molding projects:

1.1 Key Cost Components

- LSR mold tooling cost (cold runner / hot runner system)

- Medical-grade LSR raw material

- Cleanroom manufacturing environment

- Process validation & IQ/OQ/PQ

- Tooling maintenance and spare parts

- Quality control and traceability system

- Low-volume production cost during pilot phase

Among these, tooling cost and process validation usually account for the largest upfront investment.

2. Optimize Product Design to Reduce LSR Tooling Cost

2.1 Simplify Part Geometry

Complex part designs lead to:

- Multi-slide molds

- High-precision core inserts

- Complicated demolding mechanisms

To reduce investment cost:

- Avoid undercuts when possible

- Reduce micro-features if not functionally necessary

- Maintain uniform wall thickness

- Design self-demolding geometries

2.2 Design for LSR Manufacturability (DFM)

Working with an experienced LSR manufacturer early in the design phase helps you:

- Reduce mold complexity

- Lower number of cavities in the first tooling phase

- Avoid rework cost due to design changes

Early DFM analysis can save 20–40% of tooling investment.

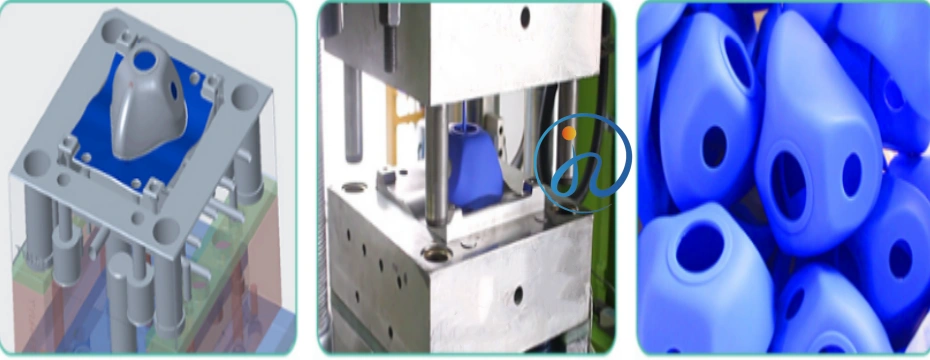

3. Choose the Right Mold Strategy to Lower Initial Investment

3.1 Start with Prototype or Soft Tooling

For early-stage medical LSR projects:

- Use aluminum or simplified steel prototype molds

- Start with 1–2 cavities instead of multi-cavity production molds

- Validate design and performance before investing in full-scale tooling

This approach significantly reduces early financial risk.

3.2 Modular Mold Design

Modular tooling allows:

- Replacing inserts instead of rebuilding the whole mold

- Upgrading cavity count later

- Faster iteration for design optimization

This spreads investment over multiple project stages.

4. Select the Right Medical LSR Material Grade

4.1 Avoid Over-Specifying Material Requirements

Many projects use overqualified medical LSR grades that exceed real application needs, increasing cost unnecessarily.

You should evaluate:

- Is USP Class VI required?

- Is ISO 10993 sufficient?

- Does the product need implant-grade silicone?

Correct material selection can reduce raw material cost by 15–30%.

4.2 Work with Manufacturer-Recommended LSR Brands

Experienced LSR manufacturers often have long-term cooperation with material suppliers (Dow, Wacker, Momentive, Elkem). This brings:

- Better pricing

- Stable supply chain

- Proven processing parameters

5. Reduce Cleanroom and Compliance Cost Strategically

5.1 Apply Cleanroom Only Where Necessary

Not all LSR medical parts require Class 7 or Class 8 cleanroom production.

Some components only need:

- Clean packaging

- Controlled environment for final assembly

Reducing cleanroom production scope can lower operational cost significantly.

5.2 Combine Validation Steps

Instead of repeating full IQ/OQ/PQ for each iteration:

- Plan validation stages carefully

- Combine validation with pilot production

- Reduce duplicated testing

6. Optimize Cavity Number & Production Volume Planning

6.1 Avoid Over-Investing in High-Cavity Tooling at Early Stage

Multi-cavity LSR molds are expensive due to:

- Cold runner system cost

- Precision temperature control

- Valve gate system

Start with low-cavity molds and scale later when order volume is stable.

6.2 Balance Cycle Time and Tooling Cost

Higher cavity count does not always mean lower unit cost in early production.

A balanced approach often reduces total investment risk.

7. Choose the Right LSR Injection Molding Partner

7.1 One-Stop Solution Manufacturer

Working with a manufacturer who provides:

- Mold design & tooling

- LSR injection molding

- Secondary operations (bonding, assembly, packaging)

- Regulatory support

helps reduce vendor management cost and shortens development cycle.

7.2 Evaluate Engineering Support Capability

An experienced medical LSR supplier can:

- Optimize part design

- Suggest cost-saving tooling structures

- Improve yield rate

- Reduce scrap rate

Long-term cooperation reduces hidden costs caused by rework and delays.

8. Use Automation to Reduce Long-Term Manufacturing Cost

Although automation increases initial equipment cost, it reduces:

- Labor cost

- Defect rate

- Human contamination risk

Examples include:

- Automated demolding

- Vision inspection

- Automated packaging

For medium-to-large production volumes, automation significantly lowers total project investment over time.

9. Reduce Cost Through Process Optimization

9.1 Improve Yield Rate

Scrap in medical LSR projects is expensive due to material and validation cost.

Optimizing:

- Injection parameters

- Mold temperature control

- Degassing process

can reduce scrap by 5–15%.

9.2 Standardize Production Parameters

Standardized process windows reduce:

- Requalification frequency

- Process drift

- Quality deviation cost

10. Long-Term Cost Strategy: Design for Scalability

Smart medical LSR project planning includes:

- Tooling scalability

- Cavity expansion design

- Material supply contract negotiation

- Volume-based pricing model

This ensures your unit cost decreases as your product scales in the market.

11. Common Mistakes That Increase Medical LSR Investment Cost

- Ignoring DFM analysis

- Over-specifying medical certifications

- Jumping directly to mass-production tooling

- Choosing suppliers without medical LSR experience

- Lack of long-term production planning

Avoiding these mistakes can prevent 30–50% unnecessary cost waste.

Conclusion

Reducing the investment cost of medical LSR projects does not mean compromising quality or compliance. By optimizing product design, choosing the right tooling strategy, selecting suitable medical-grade LSR materials, and working with an experienced manufacturing partner, OEMs and medical device companies can significantly lower both initial investment and long-term manufacturing cost.

A well-planned medical LSR project balances engineering feasibility, regulatory compliance, and cost efficiency, enabling faster market entry and sustainable profitability.