Table of Contents

ToggleWhen it comes to silicone processing, two leading technologies dominate the field: Liquid Silicone Rubber (LSR) injection molding and High-Consistency Rubber (HCR) compression or transfer molding. Both materials stem from silicone elastomers, but their processing methods, material properties, and applications differ significantly.

This article explores the key differences between LSR injection molding and HCR processing to help engineers, buyers, and manufacturers make informed decisions when selecting the right silicone for their application.

1. What Is Liquid Silicone Rubber (LSR)?

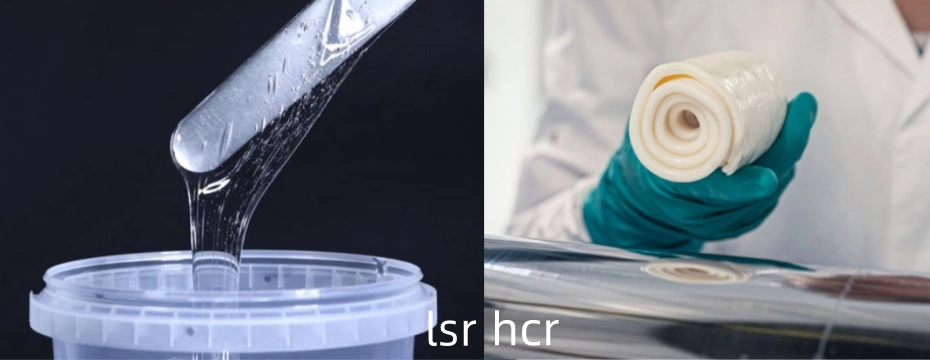

Liquid Silicone Rubber (LSR) is a two-part platinum-cured silicone elastomer with low viscosity. It is typically used in fully automated injection molding systems. The components are mixed in a 1:1 ratio and injected into heated molds under pressure.

Key Characteristics:

- Low viscosity for flow into complex mold geometries

- High purity and biocompatibility

- Fast cure cycles

- Suitable for high-volume automated production

LSR is ideal for applications requiring precision, repeatability, and clean-room compliance — such as medical, baby care, automotive, and consumer electronics.

2. What Is High-Consistency Rubber (HCR)?

High-Consistency Rubber (HCR), also known as solid silicone rubber, is a gum-based, peroxide- or platinum-cured material that has a putty-like consistency. HCR is processed via compression, transfer, or extrusion molding and often requires manual labor or semi-automated systems.

Key Characteristics:

- High green strength (maintains shape before curing)

- Better tear resistance in some formulations

- Excellent mechanical properties

- Ideal for large parts and extrusions

HCR is widely used in gaskets, seals, tubing, insulation, and custom molded parts in industrial and automotive applications.

3. LSR vs. HCR: Key Comparison Table

| Feature | Liquid Silicone Rubber (LSR) | High-Consistency Rubber (HCR) |

|---|---|---|

| Processing Method | Injection molding (automated) | Compression/transfer/extrusion molding |

| Cure System | Platinum-cured | Peroxide or platinum cured |

| Material State | Liquid (low viscosity) | Solid (high viscosity) |

| Production Volume | Best for high-volume production | Better suited for low to medium runs |

| Cycle Time | Short (fast curing) | Longer cycle times |

| Labor Requirement | Low (automated) | High (manual or semi-manual) |

| Dimensional Precision | Excellent | Moderate |

| Flash and Finishing | Minimal flash, little trimming needed | Higher flash, requires post-processing |

| Biocompatibility | Superior (medical/baby grade) | Varies by cure system |

| Initial Tooling Cost | Higher (precision steel mold) | Lower (aluminum/less complex mold) |

| Durability & Strength | High, especially for fine features | Higher in bulk mechanical parts |

4. Processing Differences

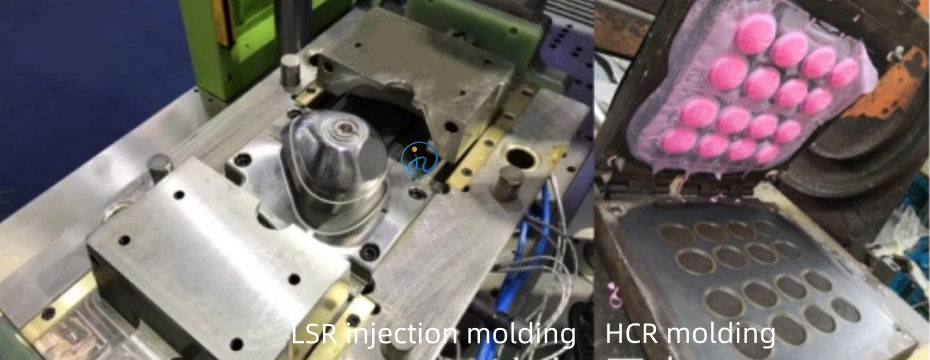

LSR Injection Molding:

- Involves fully automated dosing, mixing, and injection

- Operates in a clean-room environment (ISO 7 or ISO 8)

- Molds are heated while LSR is injected cold

- Ideal for precision micro-molding, multi-cavity tools, and 24/7 production

HCR Molding:

- Typically manual or semi-automatic loading of solid silicone into molds

- Requires pre-forming or extrusion before molding

- Cure time is longer and may require post-curing in an oven

- Suited for simple geometries, large parts, or extruded profiles

5. Cost Considerations

🔹 Tooling Cost:

- LSR: Higher upfront cost due to complex steel molds and automation

- HCR: Lower tooling investment, suitable for prototypes or custom low-volume runs

🔹 Production Efficiency:

- LSR: Lower per-part cost for large-scale production thanks to automation and short cycles

- HCR: Higher labor cost, more material waste, and longer cycles — better for small-batch needs

🔹 Post-processing:

- LSR: Minimal or no trimming due to precise molding

- HCR: Often requires secondary processes like flash removal, oven post-curing, or inspection

6. Material Properties & Performance

| Property | LSR | HCR |

|---|---|---|

| Temperature Resistance | -50°C to +250°C | -60°C to +250°C |

| Tear Strength | Moderate to High | High |

| Elongation | Up to 1000% | Up to 800% |

| Transparency | Excellent | Moderate |

| Chemical Resistance | Excellent | Good |

| Electrical Insulation | Excellent | Excellent |

Conclusion: While both materials offer excellent silicone performance, LSR excels in precision, purity, and consistency, while HCR stands out in bulk strength and adaptability.

7. Application Scenarios

When to Choose Liquid Silicone Rubber Injection Molding:

- Mass production of medical devices, baby products, or wearables

- Complex designs with fine geometries or tight tolerances

- Need for biocompatibility, clarity, and clean-room molding

- Applications requiring flash-free parts and consistent quality

When to Choose High-Consistency Rubber:

- Short-run or prototype manufacturing

- Extruded profiles, tubing, and bulk seals

- Products where post-processing is acceptable

- Applications not requiring high precision

8. Regulatory and Safety Considerations

- LSR is the preferred choice for FDA, USP Class VI, and ISO 10993-compliant products.

- HCR can also meet regulatory requirements, but peroxide-cured variants may require post-bake to remove residuals.

- For products in medical, food contact, or infant care, LSR is the safer, cleaner choice.

9. Environmental & Sustainability Insights

- LSR reduces material waste via precise injection and closed-loop processes.

- HCR may result in more offcuts and flash, though both materials are recyclable in secondary markets.

- Both types of silicone are durable and long-lasting, reducing product turnover and waste.

Final Thoughts

When choosing between Liquid Silicone Rubber injection molding and High-Consistency Rubber processing, the decision ultimately depends on your product design, budget, volume, and performance needs.

| Need | Recommended Material |

|---|---|

| High-volume, precision part | Liquid Silicone Rubber |

| Low-volume, cost-sensitive | High-Consistency Rubber |

| Clean-room production | Liquid Silicone Rubber |

| Large seals or extrusions | High-Consistency Rubber |

| Medical or baby products | Liquid Silicone Rubber |

By understanding the strengths and limitations of both LSR and HCR, manufacturers can optimize quality, efficiency, and ROI across a wide range of industries.