Table of Contents

ToggleWhen designing a product that requires the unique properties of Liquid Silicone Rubber (LSR), one of the most critical specifications you’ll encounter is LSR’s shore hardness. This isn’t just a number on a datasheet; it’s the fundamental key that unlocks performance, functionality, and user experience. Choosing the wrong Shore value can lead to product failure, while the right choice ensures longevity, safety, and perfect performance.

But what exactly is the advantage of a softer 00-30 grade versus a firmer 50A grade? This comprehensive guide will demystify the Shore scale for LSR, explore the distinct advantages of different hardness levels, and provide a clear framework to help you select the perfect grade for your application.

What is Shore Hardness and Why is it Crucial for LSR?

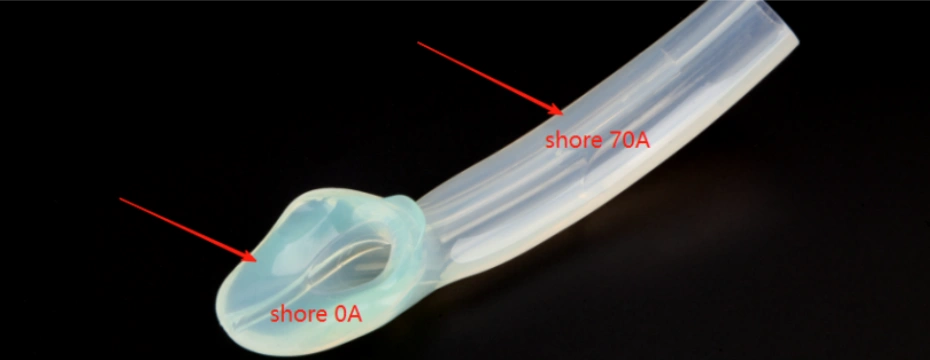

Shore hardness is a standardized measure of the resistance of a material to indentation. For elastomers like LSR, the most common scales are the Shore A and Shore 00 scales.

- Shore A Scale (0-70A): Used for harder, semi-rigid to flexible rubbers. Most LSRs fall within the 20A to 80A range.

- Shore 00 Scale (0-70): Used for very soft, gel-like, and highly flexible materials. You’ll often see LSRs like 20-00 or 30-00.

The primary advantage of understanding LSR’s shore hardness is its direct correlation to other mechanical properties. Hardness influences:

- Tensile Strength

- Tear Strength

- Compression Set

- Flexibility and Modulus (stiffness)

Essentially, Shore hardness gives you a rapid, reliable indicator of how the material will behave in the real world.

Advantages of Low Shore Hardness (Soft LSR: 00-30 to 20A)

Softer LSR grades, typically measured on the Shore 00 scale, offer a unique set of properties ideal for sensitive and high-compliance applications.

1. Superior Sealing and Gasketing

The primary advantage of soft LSR is its ability to conform to irregular surfaces effortlessly. It creates an exceptional, long-lasting seal even with low clamping force, making it perfect for dynamic gaskets in automotive housings, medical devices, and waterproof electronics enclosures.

2. Enhanced Comfort and Biocompatibility

Extremely soft LSR (e.g., Shore 00-30) mimics the feel of human tissue and is incredibly gentle on the skin. This is a massive advantage for:

- Medical Devices: Respiratory masks, cushioning for wearable devices, baby bottle nipples, and prosthetics.

- Consumer Products: Comfort-grip handles, soft-touch buttons, and ergonomic pads.

3. Excellent Damping and Shock Absorption

These materials excel at absorbing energy and dampening vibrations. This is leveraged in components like shock-absorbing mounts, protective bumpers, and dampers for precision instruments.

4. High Flexibility and Elasticity

Soft LSR can withstand extreme repeated deformation without taking a permanent set. This makes it ideal for parts that must be repeatedly stretched, twisted, or compressed, such as bellows, flexible hinges, and squeezable bulbs.

Common Applications: Medical seals, baby care products, comfort grips, soft-robotics, vibration dampeners.

Advantages of Medium Shore Hardness (Versatile LSR: 30A to 50A)

This is the most versatile range for LSR, offering a “Goldilocks” balance of flexibility and strength. The advantage of a medium LSR shore hardness is its ability to perform well in a vast array of structural and functional components.

1. Optimal Balance of Strength and Flexibility

Grades around 40A provide enough structural integrity to hold a shape and resist tearing while remaining flexible enough for snap-fits, membranes, and keypads. This balance reduces the need for complex overmolding with multiple materials in many cases.

2. Excellent Tear and Tensile Strength

As Shore hardness increases within this range, so does the material’s resistance to tearing and stretching. This is critical for parts subject to stress, such as:

- Automotive Components: Seals, grommets, and connectors.

- Industrial Parts: Diaphragms, valves, and rollers.

- Consumer Goods: Keyboard keys, remote control buttons, and tool handles.

3. Superior Processability and Detail Replication

Medium-shore LSR flows exceptionally well into intricate molds, capturing fine details and textures with high fidelity. This is a key advantage for producing complex parts with tight tolerances and aesthetic requirements.

Common Applications: Automotive seals, electrical connectors, kitchen utensil grips, multi-purpose gaskets, appliance components.

Advantages of High Shore Hardness (Firm LSR: 60A and above)

Firmer LSR grades behave more like rigid plastics but retain the inherent benefits of silicone: high-temperature resistance, biocompatibility, and excellent weathering.

1. High Structural Rigidity and Load-Bearing Capacity

The standout advantage of a high LSR shore hardness is its ability to be used in structural applications. Parts can be self-supporting, bear loads, and resist deformation under pressure. Think of components like mechanical rollers, rigid housings, or structural spacers.

2. Exceptional Abrasion and Wear Resistance

Harder LSR surfaces are more resistant to scraping, scratching, and general wear-and-tear. This extends the product’s life in high-friction applications like rollers, seals in abrasive environments, and scraper blades.

3. Maintains Key Silicone Properties at Higher Rigidity

Even at higher durometers, LSR retains its excellent thermal stability (from -60°C to +250°C), UV resistance, and chemical inertness. This allows designers to create rigid parts that perform in environments where plastics would fail.

Common Applications: Medical device housings, industrial rollers, rigid seals, high-wear components, electrical insulators.

How to Choose the Right LSR Shore Hardness: A Practical Guide

Selecting the correct hardness is a systematic process. Ask these questions:

- What is the Primary Function?

- Sealing/Conforming: Lean towards softer grades (00-30 to 30A).

- Flexing/Button-Pressing: Medium grades (40A to 50A) are ideal.

- Structural Support/Housing: Consider harder grades (60A+).

- What are the Environmental Factors?

- Will the part face extreme temperatures, chemicals, or UV? (All LSR grades perform well, but hardness can affect seal performance under thermal expansion).

- What are the Assembly and Durability Requirements?

- Does the part need to be snapped into place? (40A-50A offers good stiffness).

- Will it be subject to abrasion? (A harder surface is better).

- Prototype and Test!

- The most crucial step. Always procure material samples or create prototypes at different Shore hardness levels to test them in real-world conditions.

Conclusion: The Advantage is in the Perfect Match

There is no single “best” LSR shore hardness. The true advantage is realized when you perfectly match the material’s mechanical properties to your product’s functional, environmental, and user experience requirements.

- Leverage soft LSR for unparalleled sealing, comfort, and shock absorption.

- Utilize medium-shore LSR for a versatile balance of flexibility, strength, and processability.

- Choose hard LSR when you need structural rigidity, wear resistance, and dimensional stability.

By deeply understanding the advantages across the Shore hardness spectrum, you can make an informed decision that optimizes your product’s performance, cost, and manufacturability. Partner with your LSR material supplier and molder early in the design process to leverage their expertise and ensure your project’s success.

FAQ Section (Targeting Voice Search & Featured Snippets)

Q: What does “Shore” mean in LSR?

A: “Shore” refers to a standard scale (Shore A or Shore 00) that measures the hardness or resistance to indentation of Liquid Silicone Rubber. A higher number indicates a harder material.

Q: What is the softest LSR material?

A: The softest LSR materials are measured on the Shore 00 scale, with grades as soft as 00-10 or 00-20, offering a gel-like, highly conformable consistency.

Q: Is a higher Shore hardness stronger?

A: Not necessarily. While higher Shore hardness generally indicates greater tear strength and abrasion resistance, it also means less flexibility and conformability. “Strength” depends on the specific requirement (e.g., a soft seal is “strong” in its ability to conform).

Q: What Shore hardness is best for seals and gaskets?

A: Softer Shore hardness grades (from 00-30 up to 40A) are typically best for seals and gaskets as they can easily conform to surface imperfections to create a tight, reliable seal.