Table of Contents

ToggleChoosing the right tooling is one of the most critical decisions in Liquid Silicone Rubber (LSR) injection molding. It directly impacts your project’s budget, production efficiency, scalability, and final part quality. The central question often boils down to one key choice: a multi-cavity mold or a single-cavity mold?

Understanding the difference between these two mold types is not just about the number of parts produced per cycle; it’s about aligning your tooling strategy with your business goals. A misstep here can lead to skyrocketing costs, production bottlenecks, or quality inconsistencies.

This comprehensive guide will demystify the core differences between multi-cavity and single-cavity LSR molds. We’ll explore the advantages, disadvantages, and ideal use cases for each to empower you to make the most informed, cost-effective decision for your LSR manufacturing project.

What is a Cavity in LSR Molding?

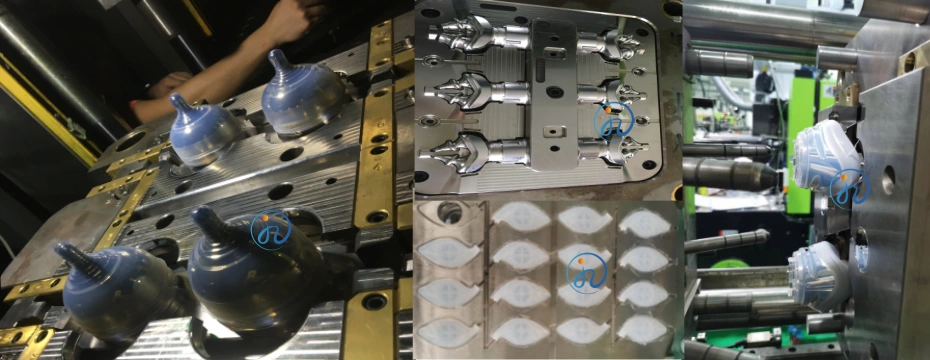

First, let’s define our terms. In injection molding, the cavity is the hollow space within a mold that is filling with liquid silicone rubber to form a part. A single-cavity mold has one of these spaces, producing one part per molding cycle. A multi-cavity mold has multiple identical cavities, allowing it to produce several identical parts every time the mold closes and opens.

The choice between the two is a fundamental trade-off between initial investment and long-term production efficiency.

The Single-Cavity LSR Mold: Precision and Simplicity

A single-cavity mold is the simpler of the two options. It’s designing to manufacture one part per cycle, focusing all the machine’s clamping force and injection pressure on that single piece.

Advantages of Single-Cavity Molds

- Lower Initial Cost: This is the most significant advantage. Single-cavity molds are less complex to design and machine. The cost of the mold base, machining time, and materials is substantially lower than a comparable multi-cavity tool. This makes them an excellent option for prototyping and low-volume production.

- Simpler Design and Maintenance: With fewer components, gates, runners, and cooling channels to manage, the design process is more straightforward. Maintenance, cleaning, and repairs are also easier and less costly.

- Reduced Risk: If a design flaw is discovered after molding begins, the financial loss is much smaller. You only need to modify or scrap one cavity, protecting a smaller investment.

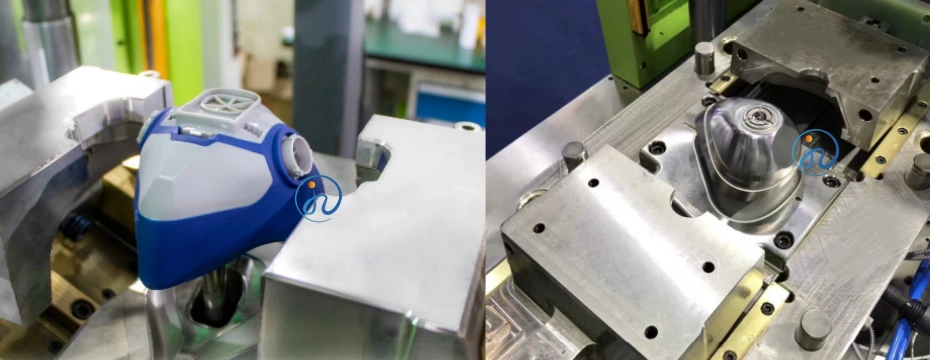

- Ideal for Large, Complex Parts: For very large LSR components (e.g., medical device housings, large gaskets), a single-cavity mold is often the only practical option. It allows the machine’s full tonnage and shot capacity to be dedicating to filling and packing out one complex part perfectly.

- Faster Time-to-Market: Due to simpler design and faster machining, you can get a single-cavity mold built and into production more quickly, which is crucial for prototyping and market testing.

Disadvantages of Single-Cavity Molds

- Higher Cost Per Part (CPP): While the mold itself is cheaper, the cost to produce each part is higher. This is because the fixed costs of the cycle time (machine time, labor, energy) are amortizing over just one part instead of many.

- Slower Production Rates: Obviously, producing one part per cycle is far slower than producing 4, 8, 16, or more. This creates a significant bottleneck for high-volume production requirements.

- Potential for Less Consistency: While a single cavity can be precise, producing all parts from the same cavity over time can lead to minor wear variations. In multi-cavity molds, parts from different cavities can be compared to identify issues like wear in a specific cavity.

The Multi-Cavity LSR Mold: Volume and Efficiency

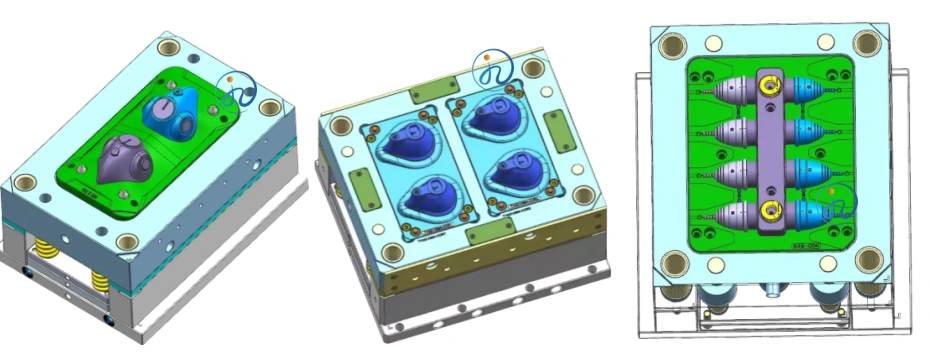

A multi-cavity mold is engineered to produce multiple, identical parts in a single molding cycle. This is achieved by replicating the cavity multiple times within the same mold base and using a runner system to deliver LSR to each cavity simultaneously.

Advantages of Multi-Cavity Molds

- Dramatically Lower Cost Per Part (CPP): This is the primary reason for choosing a multi-cavity mold. By spreading the fixed cycle cost over many parts, the individual piece price plummets. This economies-of-scale effect is essential for profitable high-volume manufacturing.

- Massive Increase in Production Output: A 16-cavity mold produces 16 parts in roughly the same cycle time as a single-cavity mold. This drastically reduces production time for large orders and increases overall equipment effectiveness (OEE).

- Superior Consistency (When Done Right): A well-designed and perfectly balanced multi-cavity mold should produce parts that are virtually identical. Modern simulation software ensures balanced filling, so every cavity receives the same amount of material at the same pressure and time, leading to exceptional part-to-part consistency.

- Reduced Factory Footprint: To achieve the same output, using a 16-cavity mold requires one machine. Using 16 single-cavity molds would require 16 machines, significantly more floor space, and vastly more operators.

Disadvantages and Challenges of Multi-Cavity Molds

- Very High Initial Cost and Lead Time: Multi-cavity molds are complex feats of engineering. The cost can be 3x to 10x+ that of a single-cavity mold. The design, machining, and polishing time is also significantly longer.

- Complex Design and Balancing: The runner system must be perfectly balanced (often using a “H” or “radial” pattern). Unbalanced molds will cause some cavities to fill faster than others, leading to flash, short shots, and inconsistent part quality and dimensions. This requires advanced design and simulation expertise.

- Higher Maintenance and Repair Costs: If one cavity is damaged, the entire mold often must be taken out of production for repair, halting all output. Repairing a single damaged cavity in a complex tool can be expensive and technically challenging.

- Increased Scrap Rates During Startup: When a multi-cavity mold is started up, it takes more time and material to balance the process and achieve stable temperature profiles across all cavities. Any process deviation can scrap dozens of parts at once instead of just one.

How to Choose: Key Decision Factors for Your LSR Project

So, which one is right for you? Ask these questions:

- What is Your Annual Volume? This is the most important question.

- < 10,000 parts/year: A single-cavity mold is almost certainly the most economical choice.

- 10,000 – 100,000 parts/year: This is a grey area. You must calculate the ROI. Compare the savings in CPP with a multi-cavity mold against its higher initial cost to see how long the “payback period” would be.

- > 100,000 parts/year: A multi-cavity mold is almost always justified by the dramatic reduction in CPP.

- What is Your Part Size? Larger parts require more machine shot capacity and clamp tonnage. There is a physical limit to how many large cavities you can fit into a mold base and still have a machine powerful enough to run it.

- What is Your Budget and Timeline? Do you have the upfront capital and time to invest in a multi-cavity tool? Or do you need a lower-cost, faster solution to get to market?

- How Stable is Your Part Design? If there is a possibility the part design will change, a single-cavity mold is a far less risky proposition. Modifying a multi-cavity mold for a design change is extremely expensive.

- What are Your Quality Requirements? For critical medical or optical components where consistency is paramount, a properly balanced multi-cavity mold can provide unbeatable consistency. However, if balance isn’t achieved, a single-cavity mold might be more reliable.

Conclusion: It’s a Strategic Business Decision

The difference between multi-cavity and single-cavity LSR molds is a classic trade-off between capital expenditure (CapEx) and operational expenditure (OpEx).

- A single-cavity mold requires low CapEx (cheaper tooling) but results in higher OpEx (higher cost per part).

- A multi-cavity mold demands high CapEx (expensive tooling) but achieves minimal OpEx (very low cost per part).

There is no universally “better” option. The right choice is a strategic one, determined by your production volume, part design, budget, and long-term business goals. By carefully weighing the factors outlined in this guide, you can select the optimal mold type that will ensure the efficiency, quality, and profitability of your LSR injection molding project for years to come.