Table of Contents

ToggleIn the world of Liquid Silicone Rubber (LSR) injection molding, choosing the right LSR mold tools is crucial for ensuring high product quality, cost-efficiency, and scalability. One of the most important decisions manufacturers face is whether to use a single cavity or a multi-cavity mold tool.

Each option offers distinct advantages and is suited to different production needs. In this comprehensive guide, we’ll explore the differences between single and multi-cavity LSR molds and provide insights to help you choose the most effective tool for your project.

What Is an LSR Mold Tool?

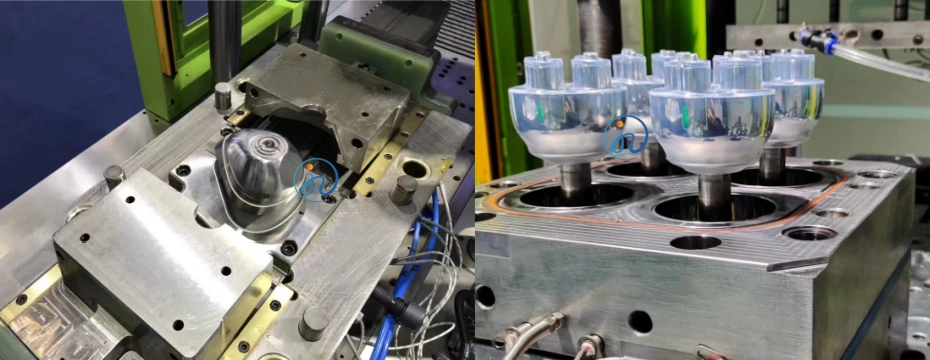

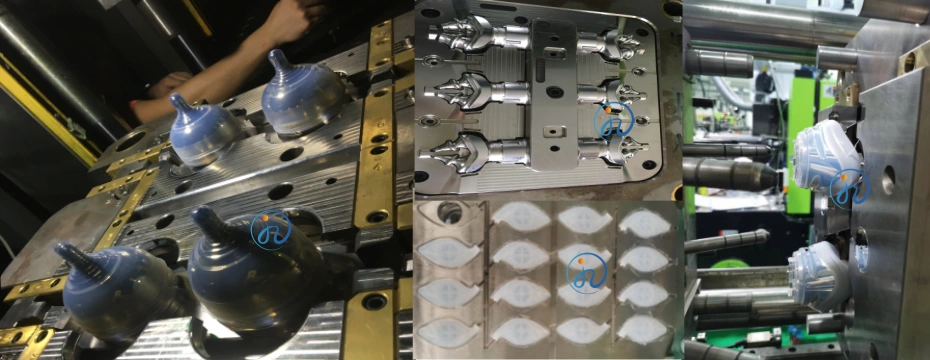

An LSR mold tool is a custom-made steel or aluminum mold used in the liquid silicone rubber injection molding process. This tool shapes the silicone into precise components under high pressure and temperature. LSR mold tools can be configured with a single cavity or multiple cavities, depending on the project requirements.

Overview of Single Cavity LSR Mold Tools

A single cavity mold produces one part per injection cycle. It consists of one mold core and one cavity, making it ideal for:

- Low to medium-volume production

- Prototyping and testing

- Complex, high-precision parts

- Projects with frequent design modifications

Pros:

- Lower initial mold cost

- Easier maintenance and setup

- High dimensional accuracy

- Less material waste during short runs

Cons:

- Slower production rates

- Higher per-part manufacturing cost

- Less suitable for large-scale manufacturing

Overview of Multi-Cavity LSR Mold Tools

A multi-cavity mold includes multiple identical cavities within one mold base. This allows several parts to be produced in a single shot, dramatically increasing output.

Pros:

- Higher production efficiency

- Reduced cycle time per part

- Lower cost per unit for high volumes

- Better use of machine time

Cons:

- Higher initial mold investment

- More complex mold design and manufacturing

- Longer lead times

- More challenging to maintain consistency across cavities

Key Differences Between Single and Multi-Cavity Tools

| Feature | Single Cavity | Multi-Cavity |

|---|---|---|

| Output per cycle | 1 part | 2+ parts |

| Tooling cost | Lower | Higher |

| Cycle time | Longer | Shorter (per part) |

| Maintenance | Simple | Complex |

| Best for | Prototypes, small batches | Mass production |

| Part consistency | Very high | Requires precise balance |

Cost Considerations

When evaluating the cost of an LSR mold tool, it’s important to consider both tooling cost and production cost:

- Single cavity molds are cheaper to manufacture and modify, making them ideal for start-ups or R&D.

- Multi-cavity molds, while more expensive upfront, offer a better return on investment (ROI) for large orders through reduced per-unit costs.

For example, if your production volume is 10,000+ parts per month, a multi-cavity mold will usually pay for itself within a short timeframe.

Productivity and Cycle Time

Cycle time is the amount of time required to complete one molding cycle. Multi-cavity molds allow for multiple parts per cycle, thus reducing the cost per part and improving overall productivity.

If your LSR component is simple in geometry and you need tens of thousands of units, multi-cavity molds can dramatically shorten production timelines.

Quality Control and Part Consistency

- Single cavity molds ensure consistent quality because every part is molded under the same conditions.

- Multi-cavity molds require precise temperature and pressure balance across all cavities. Uneven flow can lead to variations in part dimensions or flash.

Advanced technologies like cold runner systems and flow simulation software help minimize these risks in multi-cavity systems.

When to Choose Single Cavity

Opt for a single cavity LSR mold tool if:

- Your production volume is small or medium

- You’re still in the product development phase

- Your part has a complex geometry

- You plan frequent design changes

- You’re cost-sensitive at the startup phase

When to Choose Multi-Cavity

Choose a multi-cavity mold when:

- Your product is already verified and approved

- You expect high or consistent demand

- Per-part cost reduction is a priority

- Your part is simple and consistent in shape

- Your production system can handle higher throughput

Bonus Tip: Use Family Molds Wisely

If you’re manufacturing multiple similar parts, a family mold (a type of multi-cavity mold that produces different parts in one cycle) can be a cost-effective alternative. However, these are more complex to design and balance.

Conclusion

Choosing between a single cavity and a multi-cavity LSR mold tool depends largely on your production goals, budget, and timeline.

- If you prioritize flexibility, lower upfront costs, and product development, a single cavity mold is your best bet.

- If you’re scaling up to meet high volume demands and want to optimize cost-per-unit and throughput, a multi-cavity mold is the ideal solution.

Partnering with an experienced LSR mold manufacturer can help you assess your needs and make the right decision. Whether you choose a single or multi-cavity tool, the key is aligning your mold strategy with your long-term production goals.