Table of Contents

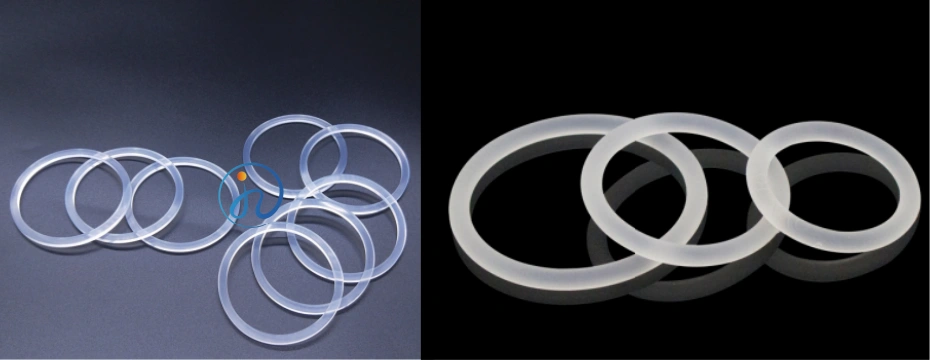

ToggleIn the medical industry, sealing performance, material safety, and dimensional accuracy are critical. Medical devices often rely on small yet vital components such as LSR rings, silicone O-rings, and sealing gaskets to ensure airtightness, fluid control, and patient safety.

As medical technology advances, more manufacturers are turning to medical LSR ring injection molding service to meet strict regulatory and performance requirements. This article explains how a professional factory offers medical-grade LSR ring injection molding services, including materials, processes, advantages, applications, and quality control.

What Is Medical LSR Ring Injection Molding Service?

Medical LSR ring injection molding service is a specialized manufacturing service that produces medical-grade silicone rings using liquid silicone rubber (LSR) through a fully automated injection molding process.

LSR rings are commonly used as:

- Medical O-rings

- Sealing rings

- Valve seals

- Fluid control gaskets

These components are molded from platinum-cured liquid silicone rubber, ensuring excellent biocompatibility, cleanliness, and long-term stability.

What Is Medical-Grade Liquid Silicone Rubber (LSR)?

Medical-grade LSR is a high-purity elastomer specifically formulated for healthcare applications.

Key Characteristics of Medical LSR

- Platinum-cured (no peroxide residues)

- Biocompatible and non-toxic

- Odorless and tasteless

- Resistant to sterilization methods

- Excellent compression set resistance

Medical LSR typically complies with:

- ISO 10993

- USP Class VI

- FDA regulations

- LFGB (for certain applications)

These properties make medical LSR ideal for rings and sealing components used in direct or indirect patient contact.

Why Choose LSR Injection Molding for Medical Rings?

Compared to traditional rubber processing, LSR injection molding offers significant advantages.

1. High Dimensional Precision

Medical LSR ring injection molding allows:

- Tight tolerances

- Consistent cross-sections

- Uniform wall thickness

- Excellent roundness

This is essential for sealing performance in medical devices.

2. Clean and Automated Manufacturing

LSR injection molding is highly automated, minimizing:

- Human contact

- Contamination risks

- Part variation

It is ideal for cleanroom or controlled production environments.

3. Superior Sealing Performance

LSR rings provide:

- Long-term elasticity

- Low compression set

- Stable sealing under pressure and temperature changes

How Medical LSR Ring Injection Molding Service Works

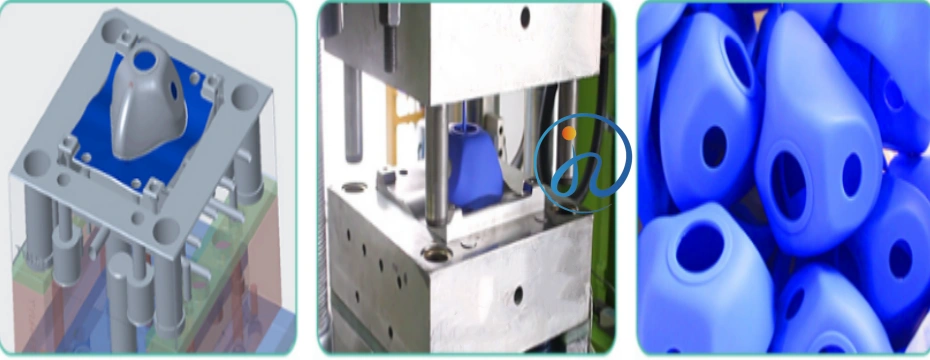

Step 1: Material Metering and Mixing

Medical-grade LSR consists of two liquid components (Part A & Part B). A precision metering system pumps and mixes them at a 1:1 ratio.

Step 2: Injection into Cold Runner System

The mixed LSR material is injected through a cold runner system, preventing premature curing and material waste.

Step 3: Mold Heating and Vulcanization

The mold is heated to activate platinum curing, forming the silicone ring rapidly and uniformly.

Step 4: Automatic Demolding

Finished medical LSR rings are automatically ejected, reducing deformation and contamination.

Step 5: Post-Processing (Optional)

- Flash trimming

- Post-curing

- Washing

- Visual inspection

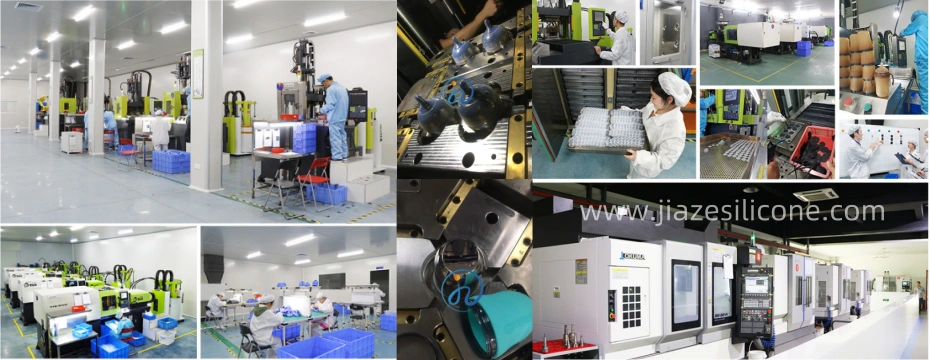

Factory Capabilities for Medical LSR Ring Injection Molding

A professional factory offering medical LSR ring injection molding service typically provides:

Custom Tooling Design

- Multi-cavity molds

- High-precision steel molds

- Optimized venting and gating

Clean Production Environment

- Dust-controlled workshops

- Optional cleanroom molding

- Strict hygiene management

Advanced Equipment

- Dedicated LSR injection molding machines

- Automated feeding and demolding systems

- Vision inspection systems

Medical Applications of LSR Rings

Medical LSR rings are widely used across healthcare fields.

Respiratory & Ventilation Devices

- Mask sealing rings

- Valve O-rings

- Connector seals

Fluid Management Systems

- Pump seals

- Syringe gaskets

- Catheter sealing components

Diagnostic & Laboratory Devices

- Instrument sealing rings

- Sensor housings

- Protective gaskets

Wearable Medical Devices

- Skin-contact sealing rings

- Waterproof seals

Tooling Design Considerations for Medical LSR Rings

Key Mold Design Factors

- Accurate parting lines

- Optimized venting to prevent air traps

- Cold runner systems for material efficiency

- Polished cavities for smooth surfaces

Tooling Cost Factors

- Ring size and cross-section

- Tolerance requirements

- Number of cavities

- Mold material and lifespan

Although tooling investment is higher, unit cost decreases significantly for mass production.

Quality Control in Medical LSR Ring Injection Molding Service

Medical applications require strict quality assurance.

Typical Quality Control Measures

- Incoming material certification

- In-process dimensional checks

- Visual inspection under magnification

- Compression and sealing tests

- Batch traceability

Certifications Commonly Required

- ISO 9001

- ISO 13485

- Material compliance documentation

Sterilization Compatibility of Medical LSR Rings

Medical LSR rings are compatible with common sterilization methods:

- Steam autoclave

- Ethylene oxide (EtO)

- Gamma radiation

- UV sterilization

This makes them suitable for reusable and disposable medical devices.

Cost Structure of Medical LSR Ring Injection Molding Service

Components Cost

- Mold tooling (one-time cost)

- Medical-grade LSR material

- Machine operation

- Quality inspection

- Secondary processing

Cost Advantages

- Low scrap rate

- Stable quality

- Long mold life

- Reduced rework cost

For high-volume medical programs, LSR injection molding offers excellent long-term value.

How to Choose the Right Factory for Medical LSR Ring Injection Molding

When selecting a manufacturing partner, consider:

- Experience in medical LSR molding

- In-house mold making capabilities

- Quality system certifications

- Material traceability

- Engineering and DFM support

- Stable production capacity

A reliable factory should support your project from design validation to mass production.

Why Our Factory Offers Reliable Medical LSR Ring Injection Molding Service

A professional factory specializing in medical LSR rings provides:

- Custom-designed molds

- Medical-grade material sourcing

- Precision injection molding

- Strict quality management

- Confidential and stable supply chain

This ensures consistent sealing performance and regulatory compliance for medical devices.

Conclusion

Medical LSR ring injection molding service is an essential manufacturing solution for modern medical devices requiring reliable sealing, biocompatibility, and precision. With advanced equipment, clean production environments, and strict quality control, professional factories can deliver high-performance medical silicone rings at scale.

Choosing the right LSR injection molding partner is critical to ensuring product safety, quality, and long-term success.

If you are looking for a trusted factory that offers medical LSR ring injection molding service, we provide custom tooling, medical-grade materials, and full production support.

👉 Contact us today to discuss your medical silicone ring project.