Table of Contents

ToggleLiquid Silicone Rubber (LSR) is a highly versatile material known for its excellent thermal stability, flexibility, and biocompatibility. One of its most critical mechanical properties is hardness, a factor that profoundly influences the performance and application of the final product. A common question among designers, engineers, and product developers is: What is the highest achievable hardness for LSR?

This comprehensive guide dives deep into the world of LSR hardness, answering that pivotal question and exploring everything you need to know about measuring, selecting, and applying this essential material property.

The Short Answer: What is the Highest Hardness of LSR?

The highest standard hardness achievable for Liquid Silicone Rubber is typically 80 Shore A.

It’s crucial to understand that Shore A is the standard scale using for measuring the hardness of elastomers like LSR, which range from soft and flexible to hard and rigid. While 80 Shore A represents the practical upper limit for most commercially available LSR compounds, it sits at the very frontier between a flexible rubber and a rigid plastic.

Understanding Hardness and the Shore Scale

Before we delve further, let’s clarify what “hardness” means in the context of LSR.

- Hardness is a measure of a material’s resistance to indentation or surface deformation. For rubbers and soft polymers, we use durometer scales, the most common being the Shore Scale.

- Shore A Scale: Ranges from 0 (extremely soft) to 80 (rigid). This scale is using for softer, flexible rubbers. Standard LSR compounds almost exclusively use this scale.

- Shore D Scale: Used for harder, semi-rigid to rigid plastics (e.g., hard hats, plastic rulers). While it’s theoretically possible to formulate LSR-like materials that approach the Shore D scale, they are no longer considering typical LSR and would be classifiing as rigid silicones.

The Hardness Spectrum of LSR: From Soft to Hard

LSR is not a one-size-fits-all material. Its hardness can be precisely formulating during production, offering a wide spectrum for different applications:

- Soft / Flexible (10 – 40 Shore A): Very pliable, gel-like, and soft-touch materials. Used for baby bottle nipples, sensitive medical cushions, and seals requiring extreme conformability.

- Medium / Standard (40 – 70 Shore A): This is the most common range for LSR. It offers a balance of flexibility, tear strength, and durability. Applications include kitchenware (spatulas), gaskets, electrical connectors, and many medical devices.

- Hard / Rigid (80 Shore A): At this high end of the spectrum, LSR becomes much more rigid while still retaining some degree of flexibility. It resists compression set excellently and is used for high-wear components, rigid seals, keypads, and automotive parts that require minimal deformation under load.

Why is There a Hardness Limit for LSR?

The chemistry of LSR dictates its physical properties. LSR is a cross-linked polymer, and its hardness is primarily determining by:

- Polymer Chain Length and Cross-link Density: Higher hardness is achieved by increasing the cross-link density—the number of molecular bonds between polymer chains. More cross-links create a tighter, more rigid network, making it harder for the material to deform.

- Fillers: Manufacturers incorporate reinforcing fillers, such as fumed silica, to increase hardness, tear strength, and modulus. The type, size, and amount of filler directly impact the final hardness.

Reaching the 80 Shore A limit is a balancing act. Pushing the chemistry beyond this point to achieve a higher hardness (e.g., 95 Shore A or higher) would require such a high filler load and cross-link density that the material would begin to lose the essential elastomeric properties that make LSR valuable—its flexibility, elongation, and tear resistance. It would become brittle and difficult to process.

Factors Influencing the Hardness of LSR

When working with LSR, it’s important to know that the stated hardness can be influencing by several factors:

- Post-Curing: LSR parts are often post-cured in an oven after molding. This process can drive the cross-linking reaction to completion, potentially increasing the final hardness by a few points on the Shore A scale.

- Temperature: Like all rubbers, LSR becomes softer at higher temperatures and harder at lower temperatures. Hardness should always be measuring at a standard room temperature (e.g., 23°C).

- Measurement Technique: Improper technique—such as pressing too hard, too softly, or on a curved surface—can lead to inaccurate readings. Measurement must be done on a flat, thick sample using a calibrated durometer according to ASTM or ISO standards.

Applications of High-Hardness LSR (70 Shore A)

Products that benefit from the highest hardness of LSR include:

- Automotive: Rigid seals, grommets, vibration-damping mounts, and connector seals that must withstand high pressure and extreme environments without deforming.

- Industrial: Rollers, wheels, valves, and diaphragms that require high abrasion resistance and durability.

- Consumer Electronics: Durable buttons, keypads, and protective boots that need to maintain a rigid feel and resist wear from repeated pressing.

- Medical: Housings for devices, components requiring minimal flex, and specialized seals for surgical instruments.

How to Choose the Right LSR Hardness for Your Project

Selecting hardness is a critical design decision. Ask these questions:

- What is the primary function? Does it need to seal (may require softer to conform), act as a grip (medium), or provide structural support (hard)?

- What are the environmental factors? Consider exposure to chemicals, temperature extremes, and UV light, which can affect material properties over time.

- What are the mechanical stresses? Will the part be under constant compression, tension, or abrasion? Higher hardness often correlates with better abrasion resistance and higher modulus (resistance to elongation).

- Prototype and Test: Always create prototypes of your part in several hardness grades (e.g., 70, 80, and 90 Shore A) to test performance in real-world conditions.

Myth Busting: Can LSR be Harder than 80 Shore A?

You might find claims or search for materials harder than 80 Shore A. Here’s the reality:

- “Shore D” LSR: If a material is marketed as an “LSR” with a hardness measured on the Shore D scale (e.g., 50 Shore D), it is almost certainly a rigid silicone resin or a plastic hybrid, not a true elastomeric Liquid Silicone Rubber. These materials are processing differently and lack the flexibility that defines LSR.

- Composite Materials: It is possible to create composite parts where a hard plastic substrate is overmolding with a layer of LSR. This gives the product a rigid structure with a soft-touch surface, but the LSR component itself is still within the Shore A scale.

Conclusion: Pushing the Limits of LSR

In summary, the pursuit of the highest hardness of LSR leads us to a clear answer: 80 Shore A. This value represents the pinnacle of rigidity while still maintaining the beneficial rubber-like characteristics of the material.

Understanding this limit and the entire spectrum of LSR hardness empowers engineers and designers to make informed decisions. While 80 Shore A is the maximum, the true genius of LSR lies in its tunability. By carefully selecting a hardness grade from the soft to the very hard, you can precisely engineer a material to meet the exact demands of your application, ensuring optimal performance, durability, and user experience.

FAQ About LSR Hardness

Q1: Is there a soft LSR? What is the lowest hardness?

A: Yes. LSR can be formulating to be extremely soft, as low as 0 Shore A (a gel-like consistency). These are used for specializing medical and cosmetic applications.

Q2: How is LSR hardness measured?

A: Hardness is measuring with a device called a durometer. The tester presses a calibrated indenter into the material under a specific spring force. The depth of indentation is translating into a hardness value on the Shore scale.

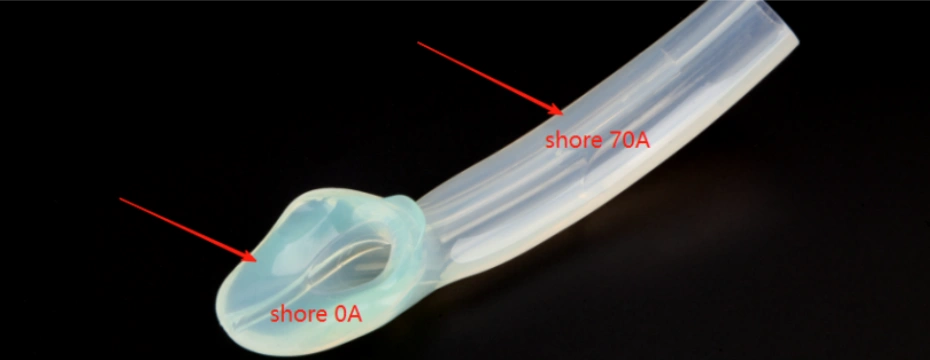

Q3: Can I mix LSR of different hardnesses?

A: Not at the user level. However, manufacturers can create two-shot molded or multi-material parts where layers of different hardnesses are chemically bonded during the molding process. This is common for products like soft-touch buttons on a rigid keypad.

Q4: Does higher hardness mean higher strength?

A: Not necessarily. While hardness often correlates with tensile strength (resistance to pulling apart) and modulus (stiffness), it does not directly equate to tear strength. Some softer compounds can have excellent tear resistance. It’s best to review the full technical data sheet for a material.