Table of Contents

ToggleLiquid Silicone Rubber (LSR) has revolutionized industries that demand exceptional durability, temperature resistance, and biocompatibility. From medical implants to automotive seals and baby care products, LSR parts are prized for their versatility and performance. However, the true potential of LSR is unlocked not just by the material itself but by the advanced tooling used to shape it—specifically, multi-part molds.

In this comprehensive guide, we’ll explore what LSR parts on a multi-part mold are, why this combination is critical for complex applications, and how it drives innovation across high-tech sectors. Whether you’re an engineer, product designer, or procurement specialist, understanding this synergy will help you optimize part quality, reduce costs, and accelerate time-to-market.

Understanding LSR Parts: Material Advantages and Applications

LSR is a two-part platinum-cured elastomer known for its:

- Thermal stability (withstanding -50°C to +250°C)

- Biocompatibility (meeting FDA and ISO 10993 standards)

- Chemical and UV resistance

- Excellent sealing and insulating properties

These traits make LSR ideal for:

- Medical devices: respiratory masks, seals, gaskets, and surgical tools

- Automotive components: ignition cables, gaskets, and sensor housings

- Consumer electronics: waterproof seals, keypads, and connectors

- Aerospace and industrial parts: vibration dampeners and insulation

Why Multi-Part Molds Are Essential for Complex LSR Parts

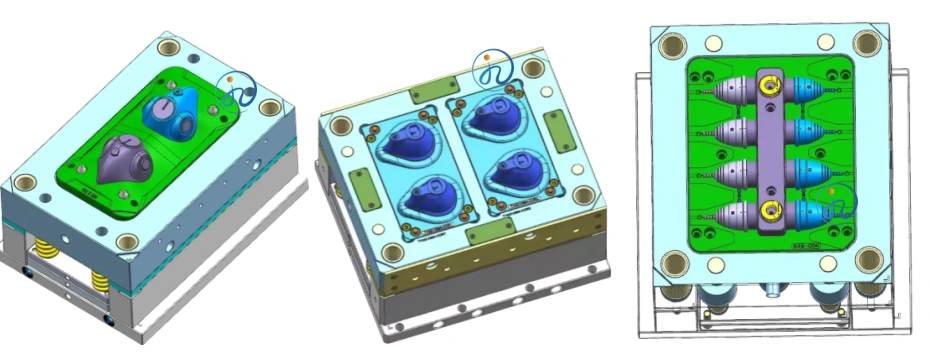

A multi-part mold refers to an injection mold with additional moving components—such as sliders, lifters, and side-actions—that enable the production of parts with complex geometries. Unlike simple two-plate molds, multi-part molds can form undercuts, internal threads, and intricate channels in a single cycle.

For LSR, this is particularly advantageous because:

- LSR’s low viscosity allows it to fill intricate cavities but also makes it prone to flashing if mold shut-offs aren’t precise. Multi-part molds provide tighter sealing surfaces.

- Complex part designs often require side-actions or cores that retract before ejection. Multi-part molds integrate these mechanisms seamlessly.

- High-volume production demands efficient cooling and venting. Multi-cavity multi-part molds maximize output while maintaining consistency.

Key Benefits of Using Multi-Part Molds for LSR Parts

1. Design Freedom for Complex Geometries

Multi-part molds enable features like undercuts, internal hinges, and integrated seals—common in LSR applications—without secondary operations. This reduces assembly time and improves part reliability.

2. Precision and Consistency

With advanced temperature control and venting channels, multi-part molds ensure uniform cure rates and minimal flash. This is critical for medical and automotive LSR parts, where tolerances can be as tight as ±0.01 mm.

3. Enhanced Venting and Air Evacuation

Trapped air causes defects like voids and burns in LSR parts. Multi-part molds incorporate additional venting at parting lines and ejector pins, improving air escape during injection.

4. Higher Productivity and Lower Costs

While multi-part molds have higher upfront costs, they reduce cycle times, scrap rates, and post-processing labor. For high-volume LSR production, this translates to significant ROI.

Design Considerations for LSR Parts on Multi-Part Molds

To optimize LSR part quality and mold longevity, follow these design principles:

Draft Angles and Wall Thickness

- Use 0.5° to 1° draft angles on cores and cavities to facilitate ejection.

- Maintain uniform wall thickness (typically 0.5–2 mm) to prevent sink marks and ensure even curing.

Gate and Runner Design

- Cold runner systems are preferred for LSR to minimize material waste.

- Position gates to ensure laminar flow and avoid air traps. Pin-point gates are common for small, precise LSR parts.

Shut-Off Surfaces and Tolerance Control

- Design steel-to-steel shut-offs at parting lines to prevent flashing.

- Account for LSR’s thermal expansion (∼3%) in mold dimensions.

Cooling and Venting

- Integrate conformal cooling channels near critical features to accelerate cycle times.

- Add micro-vents (0.005–0.015 mm deep) at weld lines and cavity ends.

The Manufacturing Process: From Mold Design to Finished LSR Parts

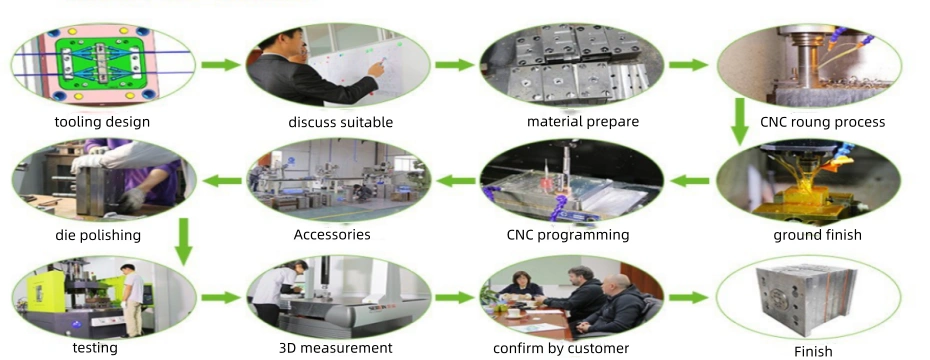

- Design for Manufacturability (DFM) Analysis

Engineers simulate LSR flow, cure time, and cooling to optimize gate locations and venting. - Precision Mold Manufacturing

Multi-part molds are CNC-machined from hardened tool steel (e.g., Stainless 420) or aluminum for prototypes. Components like sliders and lifters are fitted with wear-resistant coatings. - LSR Injection Molding Process

- Material Preparation: Two-part LSR is mixed, degassed, and fed into the injection unit.

- Injection: LSR is injected at low pressure (∼100–1,000 psi) into a heated mold (120–200°C).

- Curing: LSR vulcanizes in the mold for 15–60 seconds, depending on wall thickness.

- Ejection: Mold actions retract, and parts are ejected automatically.

- Post-Processing and Quality Control

LSR parts typically require no finishing, but some applications may need deflashing or sterilization. Each batch is testing for dimensions, hardness, and tensile strength.

Industry Applications: Where LSR Multi-Part Molds Shine

Medical Industry

- Silicone seals for syringes and inhalers: Multi-part molds produce leak-proof seals with micro-tolerances.

- Implantable device components: Complex geometries are achievable without post-mold assembly.

Automotive Electronics

- Sensor housings and connectors: Multi-part molds integrate mounting clips and cable glands directly into LSR parts.

- Battery thermal management gaskets: High-temperature resistance and sealing integrity are ensuring.

Consumer Goods

- Baby bottle nipples and utensils: Multi-cavity molds meet high-volume demand with consistent quality.

- Wearable device bands: Undercuts and textures are molding in a single step.

Future Trends in LSR Multi-Part Molding

- Automation and Industry 4.0: Sensors in molds monitor pressure and temperature in real time, adjusting parameters for zero-defect production.

- Sustainable LSR Formulations: Bio-based and recyclable LSR grades are emerging, driven by circular economy goals.

- Micro-Injection Molding: For miniaturized medical and electronic LSR parts, micro-molds with ultra-high precision are becoming standard.

Conclusion

LSR parts on multi-part molds represent the pinnacle of injection molding technology, enabling designs that were once impossible. By combining LSR’s material excellence with advanced mold engineering, manufacturers can achieve unprecedented levels of complexity, precision, and efficiency.

Whether you’re developing a life-saving medical device or a high-performance automotive component, investing in a well-designed multi-part mold for LSR is a strategic decision that pays dividends in product quality and market competitiveness.