Table of Contents

ToggleLiquid Silicone Rubber (LSR) injection molding has become a preferred manufacturing method for high-precision, medical, automotive, and consumer products. One of the most critical components in this process is the cold runner LSR mold.

So, what’s a cold runner, and why is it so important for efficient, high-quality silicone injection production?

In this guide, we’ll explain the definition, working principle, advantages, design considerations, and applications of cold runner LSR molds. This article is written for buyers, product designers, and engineers looking to understand or source LSR injection molding solutions.

What Is a Cold Runner LSR Mold?

It is a specialized injection mold system designed for Liquid Silicone Rubber molding, where the runner system is actively temperature-controlled to remain cold, preventing premature curing of the silicone rubber material before it reaches the mold cavities.

Unlike thermoplastics, LSR is a thermosetting elastomer that cures when heated. Therefore, controlling temperature throughout the mold is essential.

This unique temperature separation is what differentiates cold runner LSR molds from traditional hot runner molds used in plastic injection molding.

How Does a Cold Runner LSR Mold Work?

Understanding the working principle helps clarify why cold runner systems are indispensable for LSR processing.

Step-by-Step Working Process

- Material Feeding

Two-part LSR (Part A & Part B) is mixed and pumped into the injection unit. - Cold Runner System

The mixed LSR flows through a temperature-controlled cold runner (typically 5–20°C). - Gate Injection

LSR passes through precision valve or open gates into the mold cavities. - Heated Cavities

The cavity plates are heated (usually 160–200°C), initiating vulcanization. - Curing & Demolding

The part cures rapidly and is demolded, often automatically.

This system ensures zero material waste, high consistency, and precise part geometry.

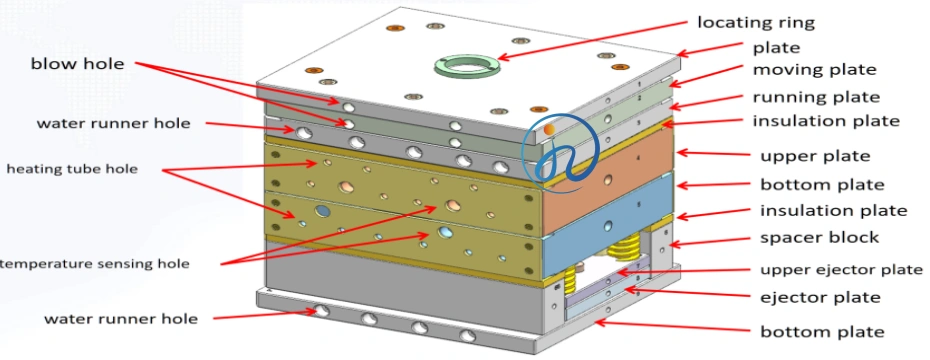

Key Components of a Cold Runner LSR Mold

A high-performance LSR injection mold consists of several critical systems:

1. Cold Runner Plate

- Integrated cooling channels

- Maintains low temperature to prevent curing

2. Valve Gate or Open Gate System

- Valve gates provide better control and surface quality

- Open gates are simpler and cost-effective

3. Heated Cavity Plates

- Uniform heating ensures consistent curing

- Cartridge heaters or heating rods commonly used

4. Precision Sealing System

- Prevents material leakage under low-viscosity conditions

- Essential for flash-free parts

5. Venting & Vacuum System

- Removes trapped air

- Improves surface finish and dimensional accuracy

Advantages of Cold Runner LSR Mold

Using a silicone injection molding mold offers multiple benefits, especially for high-volume and high-precision production.

1. Zero Material Waste

Because the runner does not cure, unused LSR can be reused, significantly reducing material costs.

2. Superior Part Quality

- No runner marks

- Minimal flash

- Excellent surface finish

3. High Production Efficiency

- Faster cycle times

- Stable long-term production

- Ideal for automation

4. Consistent Mechanical Properties

Uniform curing leads to consistent hardness, elasticity, and tear strength.

5. Suitable for Medical & Food-Grade Products

Cold runner LSR molds are widely used for:

- Medical-grade silicone parts

- FDA and LFGB-compliant products

- Cleanroom production

Common Applications of Cold Runner LSR Mold

Cold runner LSR molds are used across multiple industries:

Medical & Healthcare

- Silicone seals and gaskets

- Respiratory masks

- Catheters and valves

- Infant care products

Automotive

- Connector seals

- Wire harness grommets

- Sensor covers

Consumer Electronics

- Waterproof seals

- Keypads

- Wearable device components

Baby & Food Contact Products

- Bottle nipples

- Pacifiers

- Silicone valves and lids

Design Considerations for Cold Runner LSR Mold

Proper mold design is crucial for performance and longevity.

1. Temperature Control Accuracy

- Cold runner: ±1°C stability

- Cavity heating: uniform distribution

2. Gate Design

- Valve gates for cosmetic surfaces

- Micro-gates for precision parts

3. Parting Line & Flash Control

LSR has very low viscosity, making tight tolerances essential.

4. Mold Steel Selection

Common materials:

- S136

- Stainless steel (for medical-grade applications)

5. Automation Compatibility

Cold runner LSR molds are often paired with:

- Robotic demolding

- Automated inspection systems

How to Choose the Right Cold Runner LSR Mold Supplier

When selecting a supplier, consider:

- Experience with LSR injection molding

- In-house mold design capability

- Medical or food-grade compliance

- Quality control and testing processes

- After-sales technical support

A reliable supplier ensures stable production and long mold life.

Future Trends in Cold Runner LSR Mold Technology

- Multi-cavity high-precision molds

- Advanced valve gate systems

- Smart temperature control

- Integration with Industry 4.0 automation

- More sustainable silicone processing

Conclusion

A cold runner LSR mold is the backbone of efficient, high-quality Liquid Silicone Rubber injection molding. By maintaining precise temperature control, eliminating material waste, and enabling superior part quality, it has become the preferred solution for medical, automotive, and consumer silicone products.

If you’re planning to produce complex, high-volume LSR parts, investing in a cold runner LSR mold is not just an option—it’s a necessity.