Table of Contents

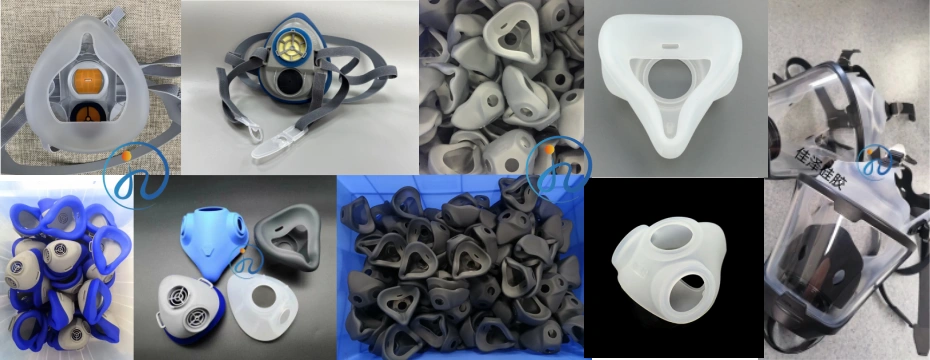

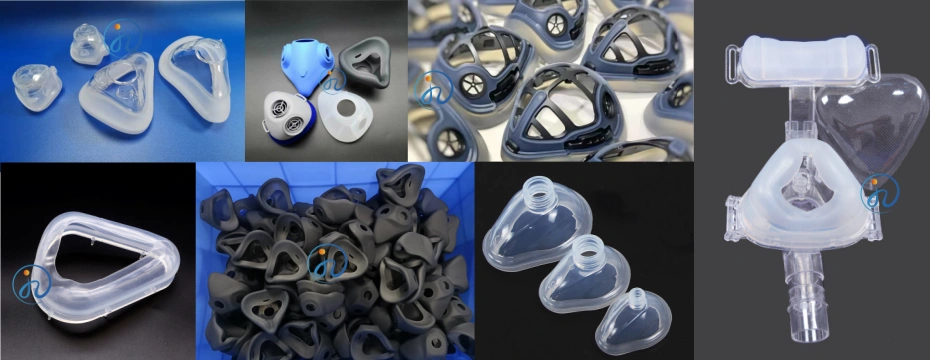

ToggleA liquid silicone mold half face mask respirator refers to a reusable respiratory protection mask manufactured by Liquid Silicone Rubber (LSR) injection molding technology. This type of half-face respirator covers the nose and mouth and is designed to provide a tight seal on the user’s face while filtering airborne particles, dust, fumes, and harmful gases when used with appropriate filter cartridges.

Compared with traditional rubber or thermoplastic respirators, LSR-molded half face respirators offer superior comfort, biocompatibility, flexibility, durability, and chemical resistance. These advantages make liquid silicone molded respirators widely used in medical, industrial, laboratory, chemical processing, painting, mining, and healthcare environments.

What Is Liquid Silicone Rubber (LSR)?

Liquid Silicone Rubber (LSR) is a two-part platinum-cured elastomer that is processed using high-precision LSR injection molding machines. It is known for:

- Excellent elasticity and softness

- High tear strength

- Skin-friendly and biocompatible properties

- Wide temperature resistance (-60°C to 200°C)

- Chemical stability

- Odorless and non-toxic performance

Because of these properties, LSR material is ideal for half face respirator masks, especially for products that are worn directly on the face for long periods.

Structure of a Liquid Silicone Half Face Mask Respirator

A typical LSR half face respirator consists of:

- LSR Mask Body – soft, flexible, face-sealing component

- Filter Cartridge Connector – usually rigid plastic or overmolded with silicone

- Head Strap System – silicone or elastic textile straps

- Exhalation Valve – silicone valve for air exhaust

- Filter Interface – connects replaceable filters

Why LSR Is Perfect for Mask Body Molding

The mask body is the most critical part of a half face respirator. Liquid silicone rubber offers:

- Excellent face-fit sealing

- No pressure pain after long wear

- Hypoallergenic and skin-safe material

- No odor or irritation

- High resilience to deformation

How Is a Liquid Silicone Mold Half Face Mask Respirator Manufactured?

1. Product Design & Engineering

The process starts with:

- 3D modeling of respirator shape

- Ergonomic face-fit design

- Filter interface compatibility

- Mold flow analysis for LSR injection molding

Design optimization ensures:

- Tight sealing

- Comfortable facial contact

- Stable wall thickness

- Easy assembly with plastic parts

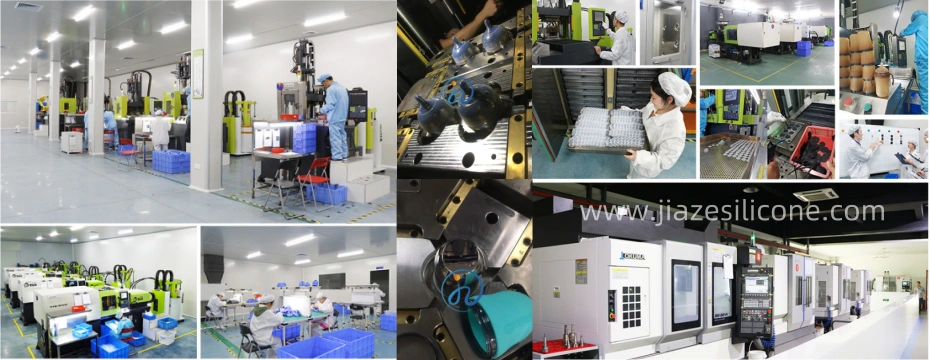

2. Liquid Silicone Rubber Mold Design

The LSR mold is typically designed with:

- Cold runner or valve gate system

- Multi-cavity mold for mass production

- High-polish cavity surface

- Precise venting structure

- Automatic demolding design

High-precision tooling is essential to ensure flash-free LSR parts and stable dimensional accuracy.

3. LSR Injection Molding Process

The liquid silicone injection molding process includes:

- Metering and mixing of two-part silicone

- Injection into heated mold cavity

- Rapid curing under controlled temperature

- Automatic demolding

- Trimming and post-processing

LSR injection molding allows:

- High repeatability

- Fully automated production

- Low scrap rate

- Clean-room manufacturing compatibility

4. Secondary Processing & Assembly

After molding, respirator components go through:

- Visual inspection

- Dimensional measurement

- Assembly with filter connectors

- Strap installation

- Air tightness testing

- Functional validation

5. Quality Control & Compliance Testing

For medical and industrial respirators, factories usually perform:

- Airtight sealing test

- Tensile strength testing

- Tear resistance testing

- Material safety testing

- Aging and durability testing

Advantages of Liquid Silicone Mold Half Face Mask Respirators

1. Superior Comfort

LSR is extremely soft and skin-friendly, providing:

- Comfortable long-term wear

- Reduced facial pressure

- Better fit for different face shapes

2. Excellent Sealing Performance

Liquid silicone creates:

- Tight contact with facial contours

- Reduced air leakage

- Improved filtration efficiency

3. Chemical & Temperature Resistance

LSR respirators perform well in:

- Chemical plants

- High humidity environments

- Extreme temperature workplaces

4. Long Service Life

Compared with rubber or TPE masks, LSR masks offer:

- Longer durability

- Less aging and cracking

- Better elasticity retention

5. Safe & Non-Toxic Material

Medical-grade or food-grade silicone can be used to meet:

- FDA

- ISO

- ROHS

- REACH

- Biocompatibility requirements

Applications of Liquid Silicone Mold Half Face Mask Respirators

LSR half face respirators are widely used in:

- Industrial manufacturing

- Painting and coating workshops

- Chemical processing plants

- Pharmaceutical production

- Medical protection

- Laboratories

- Mining and construction sites

Custom Liquid Silicone Half Face Mask Respirator Manufacturing

More brands are choosing custom LSR respirator mask solutions. Customization options include:

- Mask shape and size

- Logo embossing on silicone

- Color customization

- Filter interface standards

- Strap design

- Valve structure design

Custom LSR Mask OEM/ODM Services

Professional LSR injection molding factories provide:

- DFM (Design for Manufacturing)

- Mold development

- Prototyping

- Mass production

- Packaging customization

- Private labeling

Key Considerations When Choosing an LSR Respirator Manufacturer

When selecting a liquid silicone respirator mask factory, consider:

- Experience in LSR injection molding

- Medical or industrial compliance capability

- Mold design and manufacturing capability

- Cleanroom production environment

- Quality control system

- Customization and OEM support

- Export experience for US and EU markets

Market Trends of Liquid Silicone Respirator Masks

The global PPE market is moving toward:

- Reusable protective equipment

- Skin-friendly and ergonomic designs

- Sustainable and durable materials

- Custom-branded respirators

- Higher filtration efficiency

LSR half face respirators align perfectly with these trends due to their premium performance and long-term value.

Conclusion

A liquid silicone mold half face mask respirator is a high-performance protective mask manufactured using LSR injection molding technology, offering superior comfort, sealing, durability, and safety compared to traditional rubber masks. With increasing global demand for high-quality PPE, liquid silicone half face respirators are becoming the preferred choice for medical, industrial, and professional protection applications.

For brands and importers, partnering with an experienced LSR injection molding factory enables cost-effective mass production, custom design flexibility, and consistent product quality for global markets.