Table of Contents

ToggleA Medical-Grade Silicone Mould is a precision-engineered mold used to manufacture silicone components intended for medical and healthcare applications. These molds are specifically designed to process medical-grade silicone materials under tightly controlled conditions to ensure safety, biocompatibility, consistency, and compliance with international medical standards.

Medical-grade silicone moulds play a critical role in producing components such as medical tubing, seals, gaskets, valves, catheters, implantable parts, and wearable healthcare devices. Because these products often come into direct or indirect contact with the human body, the moulds used to create them must meet far stricter requirements than standard industrial silicone moulds.

Understanding Medical-Grade Silicone

Before discussing the mould itself, it is important to understand the material it processes.

What Is Medical-Grade Silicone?

Medical-grade silicone is a high-purity elastomer formulated to meet stringent regulatory and biological safety standards. It is typically used in applications that require:

- Biocompatibility

- Chemical stability

- Sterilization resistance

- Long-term durability

Most medical silicone products are manufactured using Liquid Silicone Rubber (LSR) or High-Consistency Rubber (HCR) that complies with standards such as USP Class VI, ISO 10993, or FDA regulations.

A Medical-Grade Silicone Mould must be designed to handle these materials without contamination or degradation.

What Makes a Medical-Grade Silicone Mould Different?

A Medical-Grade Silicone Mould differs significantly from conventional silicone or plastic moulds in several key areas.

1. Material Selection for the Mould

Medical moulds are usually made from high-grade stainless steel (such as S136 or 420 stainless steel) or other corrosion-resistant tool steels. These materials provide:

- Superior surface finish

- Resistance to wear and corrosion

- Compatibility with cleanroom environments

This ensures the mould can withstand repeated sterilization and long production cycles without compromising quality.

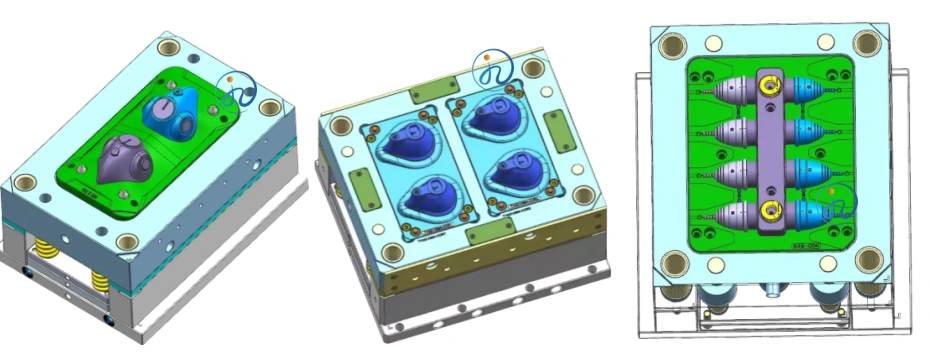

2. High-Precision Design and Tolerances

Medical devices often require extremely tight tolerances. A Medical-Grade Silicone Mould is designed using advanced CAD/CAM systems to achieve:

- Micro-level dimensional accuracy

- Consistent wall thickness

- Smooth, flash-free surfaces

Even minor defects can lead to product failure or regulatory rejection, making precision essential.

3. Cleanroom Compatibility

Many medical silicone parts are produced in ISO Class 7 or Class 8 cleanrooms. Medical-grade silicone moulds are engineered to:

- Minimize particle generation

- Reduce dead corners where contaminants may accumulate

- Support automated, closed-loop production systems

This ensures compliance with medical manufacturing cleanliness requirements.

Types of Medical-Grade Silicone Moulds

Different medical applications require different mould structures. Common types include:

Liquid Silicone Rubber (LSR) Injection Moulds

LSR injection moulds are the most widely used medical-grade silicone moulds. They support:

- Fully automated injection processes

- High-volume, repeatable production

- Excellent surface quality

These moulds are ideal for producing catheters, seals, diaphragms, and wearable medical components.

Medical-Grade Silicone Mould Manufacturing Process

The production of a Medical-Grade Silicone Mould follows a strict, multi-step process.

Step 1: Product and Mould Design

The process begins with:

- Product geometry analysis

- Material flow simulation

- Draft angle and parting line design

Design engineers ensure the mould supports proper curing, easy demoulding, and zero contamination risk.

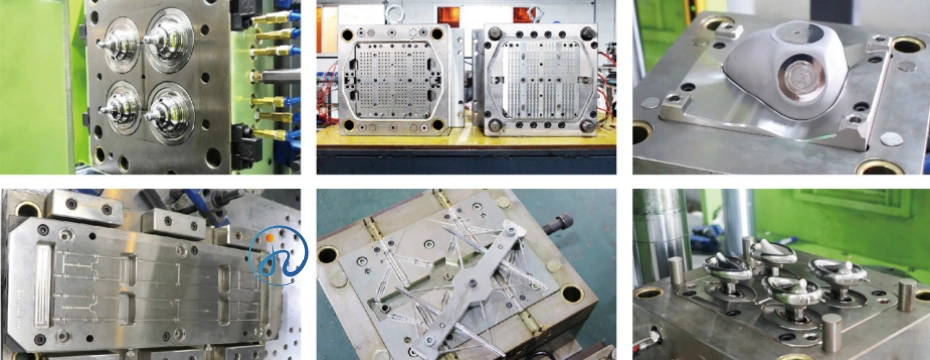

Step 2: Tool Steel Machining

Using CNC machining, EDM, and precision polishing, the mould cavity is manufactured to exact specifications. Medical moulds often require mirror-polished surfaces to prevent bacterial adhesion and ensure easy cleaning.

Step 3: Surface Treatment and Polishing

Medical-grade moulds undergo advanced polishing processes such as:

- SPI A-grade polishing

- Electropolishing

This improves product appearance and reduces microbial risk.

Step 4: Validation and Testing

Before production, the Medical-Grade Silicone Mould is validating through:

- Trial moulding runs

- Dimensional inspections

- Process capability studies (CPK)

Validation ensures consistent quality over long production cycles.

Standards and Certifications for Medical-Grade Silicone Moulds

Compliance is critical in medical manufacturing. A professional Medical-Grade Silicone Mould supplier must support production that meets global standards.

Common Standards Include:

- ISO 13485 – Medical device quality management

- ISO 10993 – Biological evaluation of medical devices

- USP Class VI – Biocompatibility testing

- FDA 21 CFR – U.S. medical regulations

While the mould itself is not certified, it must be capable of producing parts that meet these regulatory requirements consistently.

Applications of Medical-Grade Silicone Moulds

Medical-grade silicone moulds are used across a wide range of healthcare sectors.

Medical Devices

- Seals and O-rings

- Valves and diaphragms

- Tubing connectors

Implantable and Long-Term Contact Products

- Implant housings

- Soft tissue interfaces

- Surgical components

Wearable and Home Healthcare Devices

- Respiratory masks

- Monitoring device components

- Skin-contact medical accessories

Advantages of Using Medical-Grade Silicone Moulds

Choosing the right Medical-Grade Silicone Mould offers several benefits:

- High consistency and repeatability

- Superior product safety and reliability

- Reduced risk of contamination

- Long mould life and stable performance

These advantages are essential for meeting the strict demands of medical device manufacturing.

How to Choose the Right Medical-Grade Silicone Mould Manufacturer

Selecting a qualified supplier is critical for success.

Key Factors to Consider

- Medical Manufacturing Experience

Choose a manufacturer with proven experience in medical silicone moulding. - Cleanroom Production Capability

Ensure they support cleanroom moulding environments. - Engineering and DFM Support

A strong engineering team helps optimize mould design and reduce costs. - Quality Management System

ISO 13485 certification is a strong indicator of reliability. - Material Knowledge

The supplier should understand medical-grade LSR behavior and curing characteristics.

Common Challenges in Medical-Grade Silicone Moulding

Despite its advantages, medical silicone moulding presents challenges:

- Complex mould design requirements

- High tooling cost

- Strict validation and documentation needs

An experienced mould manufacturer can mitigate these risks through proper design, testing, and process control.

Future Trends in Medical-Grade Silicone Mould Technology

The medical industry continues to evolve, driving innovation in silicone moulding.

Emerging Trends Include:

- Micro-moulding for minimally invasive devices

- Multi-shot silicone moulding

- Integration with automation and robotics

- Increased demand for wearable medical devices

Medical-Grade Silicone Moulds will continue to play a key role in advancing medical technology.

Conclusion

A Medical-Grade Silicone Mould is far more than a simple tool—it is a critical foundation for producing safe, reliable, and compliant medical silicone products. From material selection and precision engineering to cleanroom compatibility and regulatory support, every aspect of the mould impacts final product quality.

For medical device manufacturers, partnering with an experienced Medical-Grade Silicone Mould supplier ensures long-term success, regulatory compliance, and consistent product performance in a highly regulated industry.