Table of Contents

ToggleLiquid Silicone Rubber (LSR) full overmolding manufacturing is a specialized injection molding process where liquid silicone rubber is molded over or around another substrate — such as plastic, metal, or other silicone components — to create a single, integrated part. Unlike traditional molding that forms standalone silicone products, full overmolding produces multi-material parts with superior bonding, sealing, and durability.

This process is widely used in industries such as medical devices, consumer electronics, baby products, automotive, and industrial equipment, where high precision, biocompatibility, and performance are essential.

1. Understanding LSR Full Overmolding

In simple terms, full overmolding means the liquid silicone rubber completely encapsulates the substrate, creating a seamless protective layer or functional interface.

Key characteristics of LSR full overmolding include:

- Material integration – The LSR chemically or mechanically bonds with the substrate.

- High precision molding – Ideal for complex geometries and tight tolerances.

- Enhanced performance – Offers properties like waterproofing, thermal stability, and chemical resistance.

Difference from partial overmolding:

- Full overmolding: LSR entirely covers the part.

- Partial overmolding: Only certain areas of the substrate are covered for grip or sealing purposes.

2. How the LSR Full Overmolding Process Works

The manufacturing process involves several key stages:

Step 1: Substrate Preparation

- Material choice – Common substrates include thermoplastics (PC, PBT, PA), metals, or glass.

- Surface treatment – Methods like plasma treatment, priming, or mechanical texturing improve adhesion.

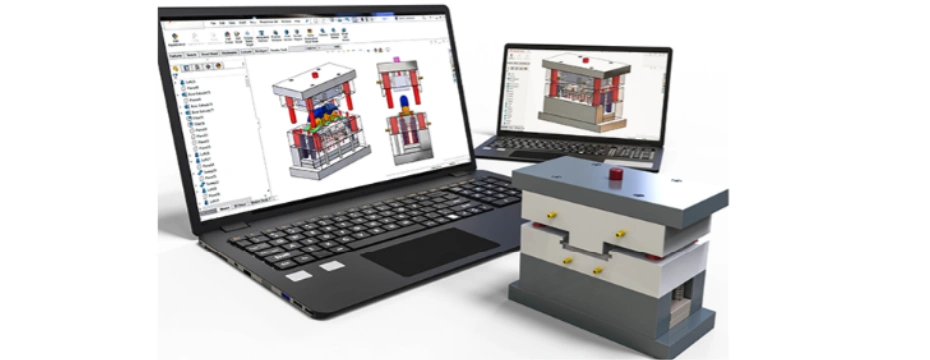

2: Mold Design & Engineering

- Precision cavities are designed to fit both the substrate and the silicone overmold.

- Gating & venting systems ensure proper silicone flow and air release.

3: LSR Injection Molding

- The LSR is mixed from two components (A & B), often with color pigment, and injected into the mold at controlled temperatures.

- The silicone flows around and fully encapsulates the substrate.

4: Curing

- LSR is heat-cured inside the mold, typically between 120°C to 200°C, forming a permanent bond with the substrate.

5: Demolding & Quality Control

- The completed overmolded part is removed.

- Dimensional checks, adhesion tests, and visual inspections ensure quality.

3. Advantages of LSR Full Overmolding

Choosing LSR full overmolding offers significant benefits:

1. Superior Bonding Strength

The silicone becomes part of the component, reducing the risk of delamination or peeling.

2. Waterproof and Dustproof Protection

Ideal for IP-rated devices like wearable electronics or medical sensors.

3. Enhanced Comfort and Safety

Soft-touch surfaces improve ergonomics for baby pacifiers, grips, or wearable bands.

4. High Temperature and Chemical Resistance

Withstands extreme environments, from -50°C to +200°C, and resists oils, fuels, and cleaning agents.

5. Design Flexibility

Enables the creation of parts with complex geometries, intricate sealing features, and integrated functions.

4. Common Applications of LSR Full Overmolding

The versatility of this process makes it valuable across industries:

- Medical devices – Catheters, masks, diagnostic equipment handles.

- Consumer electronics – Smartwatch bands, earbud tips, waterproof casings.

- Baby products – Pacifiers, bottle nipples, teething toys.

- Automotive – Gaskets, buttons, vibration dampers.

- Industrial tools – Grips, seals, sensor housings.

5. Design Considerations for LSR Full Overmolding

When designing parts for this process, engineers should consider:

- Material Compatibility – Ensure LSR bonds with the chosen substrate; certain plastics require primers.

- Wall Thickness – Uniform thickness avoids sink marks and ensures consistent curing.

- Undercuts & Geometry – Design for mold release without damaging the silicone layer.

- Shrinkage Compensation – LSR shrinks slightly during curing; mold dimensions must account for this.

- Gate Location – Strategic placement prevents flow marks or air entrapment.

6. Quality Control in LSR Full Overmolding

Typical quality checks include:

- Adhesion testing (peel, shear tests).

- Dimensional accuracy measurement.

- Visual inspection for flash, bubbles, or incomplete fill.

- Functional testing (leak tests for sealing parts).

7. Why Industries Choose LSR Full Overmolding

This manufacturing method solves challenges where:

- A single-material part cannot meet performance requirements.

- Bonding between soft and hard materials is needed.

- High hygiene standards require seamless, non-porous surfaces.

For example, medical masks overmolded with LSR offer comfort and a perfect face seal, while electronics with LSR overmolding achieve waterproofing without gaskets.

8. Sustainability and LSR Overmolding

LSR is non-toxic, hypoallergenic, and recyclable. Manufacturers can reduce waste through:

- Runnerless cold-deck systems to avoid material waste.

- Precision molding to minimize defective parts.

- Long product lifespans reducing replacement needs.

Conclusion

LSR full overmolding manufacturing is a high-precision, high-performance production method that integrates the exceptional properties of liquid silicone rubber with other materials to create durable, functional, and safe products. Its versatility, biocompatibility, and design freedom make it a go-to solution in demanding industries like healthcare, electronics, automotive, and consumer goods.

Companies looking to innovate with multi-material parts can leverage LSR full overmolding to enhance performance, aesthetics, and market competitiveness.