Table of Contents

ToggleMedical LSR silicone parts refer to medical components manufactured from Liquid Silicone Rubber (LSR) using precision injection molding technology. These parts are widely used in medical devices, healthcare equipment, respiratory systems, wearable medical products, and patient-contact components due to their biocompatibility, flexibility, durability, and safety.

Medical-grade LSR silicone parts are designed to meet strict healthcare standards and regulations. Compared with traditional rubber, PVC, or TPE materials, LSR medical parts offer superior performance in skin contact safety, sterilization resistance, chemical stability, and long-term reliability.

What Is Medical-Grade Liquid Silicone Rubber ?

Medical-grade Liquid Silicone Rubber is a two-component platinum-cured elastomer specifically formulated for medical and healthcare applications. It is processed through automated LSR injection molding systems in clean manufacturing environments.

Key Properties of Medical LSR Silicone

- Excellent biocompatibility

- Non-toxic and odorless

- Soft and flexible touch

- High tear and tensile strength

- Excellent sealing performance

- Resistance to high temperature sterilization

- Stable chemical resistance

- Long service life

Medical LSR materials typically comply with:

- ISO 10993 (biocompatibility)

- USP Class VI

- FDA regulations

- ROHS & REACH

Common Types of Medical LSR Silicone Parts

The parts are used across a wide range of medical and healthcare products, including:

- Silicone seals and gaskets for medical devices

- Medical-grade silicone O-rings

- Silicone diaphragms and membranes

- Respirator mask components

- Silicone valves for fluid control

- Medical tubing connectors

- Wearable medical device housings

- Infant and maternal care silicone parts

- Drug delivery device components

- Surgical instrument grips

These parts often require custom LSR injection molding tooling to meet specific functional and regulatory requirements.

Manufacturing Process of Medical LSR Silicone Parts

1. Product Design & DFM

The process begins with:

- Medical device application analysis

- Material selection (medical-grade LSR)

- Design for Manufacturing (DFM)

- Mold flow simulation

- Tolerance and sealing structure optimization

Medical LSR parts require high dimensional accuracy and smooth surface finish to ensure patient safety and functional performance.

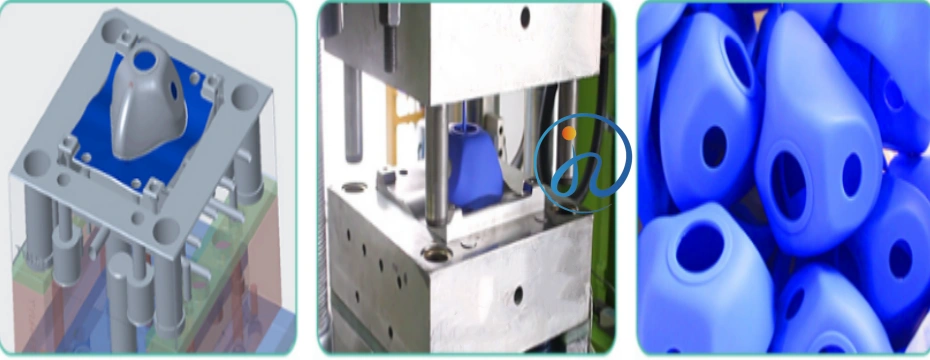

2. Medical LSR Injection Mold Design

Medical LSR molds are typically designed with:

- Cold runner or valve gate system

- Precision cavity machining

- Mirror-polished cavity surfaces

- Flash-free sealing structure

- Multi-cavity for mass production

- Automated demolding system

Proper mold design is critical to ensure consistent quality, low scrap rate, and stable mass production.

3. Medical LSR Injection Molding Process

The LSR injection molding process includes:

- Metering and mixing of two-part silicone

- Injection into heated mold

- Rapid curing under controlled temperature

- Automatic demolding

- Trimming and post-processing

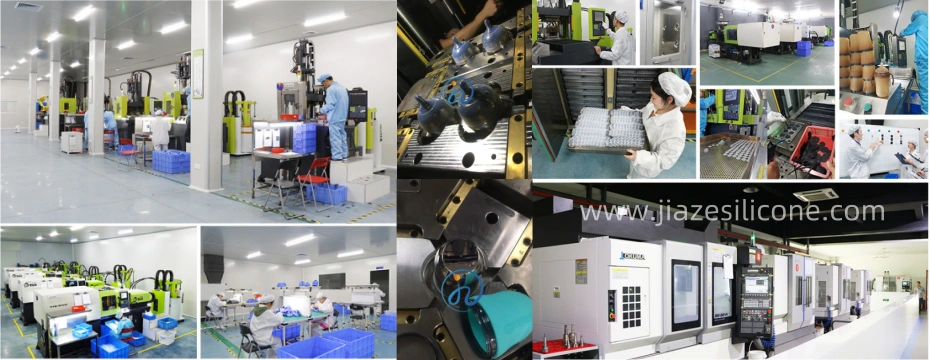

Medical LSR molding is often performed in:

- Cleanroom environments

- Dust-controlled workshops

- Fully automated production lines

4. Post-Processing and Secondary Operations

After molding, medical silicone parts may undergo:

- Deflashing

- Washing and cleaning

- Secondary curing (if required)

- Assembly with plastic or metal parts

- Overmolding with rigid substrates

- Surface treatment or marking

5. Quality Control and Validation

The parts must pass strict quality checks:

- Dimensional inspection

- Visual inspection

- Material certification

- Biocompatibility compliance

- Tensile and tear strength tests

- Aging and durability tests

- Sterilization compatibility tests

Advantages of Medical LSR Silicone Parts

1. Superior Biocompatibility

Medical LSR silicone is safe for prolonged skin contact and even internal medical device use, reducing the risk of allergic reactions and irritation.

2. Excellent Comfort and Flexibility

The soft and elastic nature of LSR ensures:

- Comfortable patient contact

- Better sealing performance

- Improved user experience

3. High Temperature Sterilization Resistance

LSR parts can withstand:

- Steam sterilization

- Autoclaving

- UV sterilization

- Chemical disinfection

4. Long-Term Stability and Durability

Medical LSR maintains mechanical properties over time, even in harsh medical environments.

5. Clean and Odorless Material

LSR does not release harmful substances, making it ideal for sensitive medical applications.

Applications of Medical LSR Silicone Parts

The parts are widely applied in:

- Respiratory therapy equipment

- Patient monitoring devices

- Medical wearable products

- Drug delivery systems

- Diagnostic equipment

- Hospital consumables

- Rehabilitation devices

- Neonatal and infant care products

- Surgical tools and accessories

Custom Medical LSR Silicone Parts OEM & ODM Services

Medical device companies increasingly seek custom LSR silicone parts suppliers that can provide:

- Product design support

- Rapid prototyping

- Mold development

- Medical-grade material selection

- Cleanroom mass production

- Assembly and packaging services

- Export compliance support

Customization options include:

- Custom shapes and sizes

- Silicone hardness (Shore A)

- Color customization

- Logo embossing

- Overmolding with plastics or metals

How to Choose a Reliable Medical LSR Silicone Parts Manufacturer

When selecting a supplier, consider:

- Experience in medical LSR injection molding

- Medical-grade material sourcing

- Compliance with ISO 13485 quality system

- Cleanroom manufacturing capability

- Mold design and tooling in-house

- Strict quality control procedures

- Export experience for US and EU medical markets

A professional medical LSR supplier helps reduce risk and ensures stable long-term cooperation.

Conclusion

Medical LSR silicone parts are essential components in modern medical devices and healthcare products. Manufactured through liquid silicone rubber injection molding, these parts offer unmatched biocompatibility, comfort, durability, and safety. As medical technology continues to advance, the demand for high-quality, custom medical LSR silicone components will continue to grow.

For medical brands, device manufacturers, and healthcare equipment suppliers, partnering with a reliable medical LSR injection molding manufacturer ensures stable quality, regulatory compliance, and scalable production for global markets.