Table of Contents

ToggleOptical Liquid Silicone Rubber (Optical LSR) is a high-purity, ultra-transparent silicone elastomer specifically engineered for optical and light-transmission applications. Compared with standard Liquid Silicone Rubber (LSR), Optical LSR offers exceptional clarity, low birefringence, excellent light transmittance, and long-term optical stability, making it ideal for lenses, light guides, optical seals, and illumination components.

With the rapid growth of LED lighting, automotive optics, medical devices, and consumer electronics, Optical LSR has become an essential material for manufacturers seeking high-performance optical components combined with flexible design and reliable injection molding production.

1. What Is Optical Liquid Silicone Rubber?

Optical Liquid Silicone Rubber is a two-component platinum-cured silicone elastomer designed to achieve high optical clarity and precision molding. It is processed using LSR injection molding technology, allowing manufacturers to produce complex optical components with consistent quality and tight tolerances.

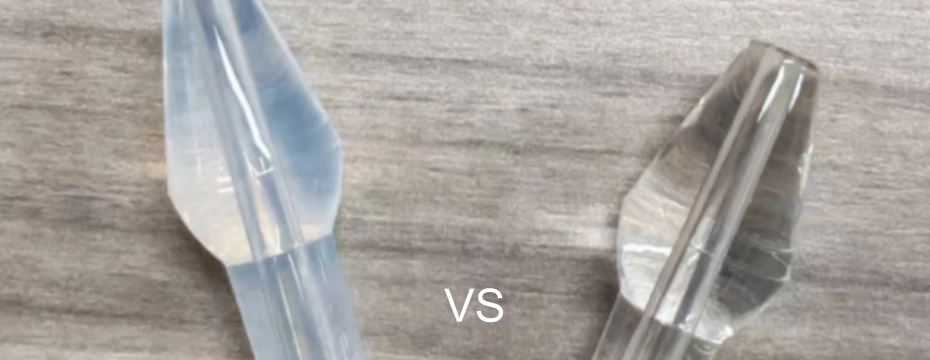

Unlike conventional optical plastics such as PMMA or polycarbonate, Optical LSR combines rubber-like flexibility with glass-like transparency, making it suitable for applications where durability, flexibility, and optical performance are all required.

2. How Optical LSR Differs from Standard LSR

Although Optical LSR belongs to the LSR family, it differs significantly from general-purpose liquid silicone rubber.

| Feature | Standard LSR | Optical LSR |

|---|---|---|

| Transparency | Good | Ultra-clear |

| Light Transmittance | Medium–High | Very High |

| Birefringence | Not controlled | Extremely low |

| Optical Stability | General | Excellent |

| Application Focus | Seals, gaskets | Lenses, optics, lighting |

Optical LSR is specially formulated to minimize impurities, bubbles, and internal stress, which are critical factors for optical components.

3. Key Properties of Optical Liquid Silicone Rubber

Optical LSR is valued for a combination of mechanical, thermal, and optical properties:

High Transparency

Optical LSR can achieve light transmittance above 90%, comparable to glass in many visible-light applications.

Excellent Elasticity

Despite its optical clarity, the material retains silicone’s inherent elasticity and flexibility, enabling impact resistance and vibration absorption.

Thermal Stability

- Operating temperature range: -40°C to +200°C

- Maintains optical performance under long-term heat exposure

UV and Weather Resistance

Optical LSR resists:

- UV radiation

- Yellowing

- Aging and cracking

This makes it ideal for outdoor and automotive lighting applications.

4. Optical Performance Characteristics

Optical Liquid Silicone Rubber is engineered to meet strict optical requirements:

Low Birefringence

Low birefringence ensures minimal light distortion, critical for lenses and precision optics.

High Refractive Index Options

Optical LSR materials can be customized with specific refractive indices, allowing precise control of light direction and diffusion.

Surface Replication Accuracy

LSR injection molding allows excellent surface finish replication, including micro-textures used in optical lenses and light diffusers.

5. Common Applications of Optical LSR

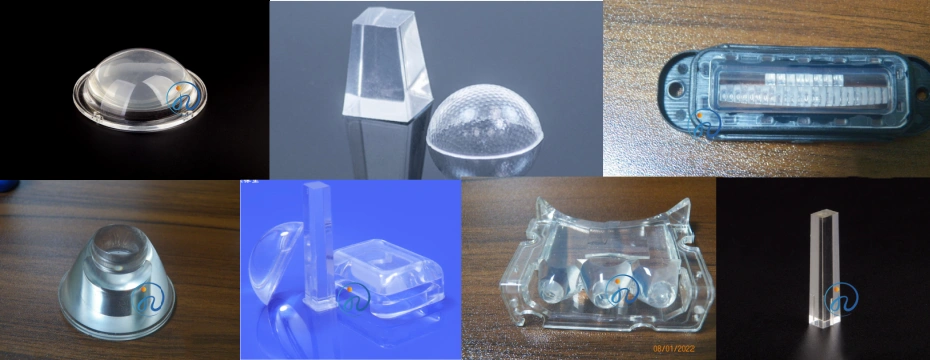

Optical LSR is widely used across multiple high-tech industries:

LED Lighting Components

- LED lenses

- Light guides

- Diffusers

- Secondary optics

Automotive Optics

- Headlamp lenses

- Interior ambient lighting

- Sensor covers

- Camera housings

Medical Optical Devices

- Endoscope components

- Diagnostic device lenses

- Optical seals requiring biocompatibility

Consumer Electronics

- Optical buttons

- Light windows

- Wearable device optics

6. Optical LSR Injection Molding Process

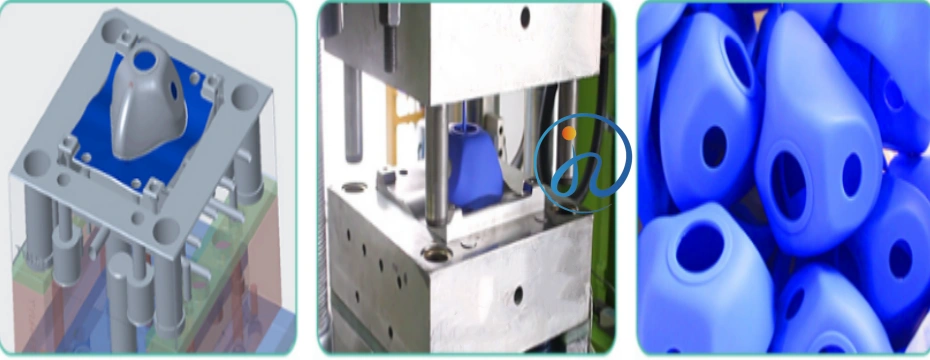

Optical Liquid Silicone Rubber is processed using precision LSR injection molding, which ensures consistent optical quality and high production efficiency.

Step 1: Material Preparation

Two silicone components (A & B) are precisely metered and mixed with optical-grade additives.

Step 2: Injection into Heated Mold

The material is injected into a highly polished steel mold, typically heated between 150–200°C.

Step 3: Vulcanization

Optical LSR cures rapidly under heat, forming a solid elastomer with excellent optical clarity.

Step 4: Demolding & Inspection

Parts are automatically demolded and inspected for:

- Bubbles

- Flow lines

- Optical distortion

Cleanroom molding environments are often used for high-end optical applications.

7. Design Considerations for Optical LSR Parts

Designing optical components with LSR requires close collaboration between engineers and mold manufacturers.

Wall Thickness Uniformity

Uniform thickness helps prevent:

- Optical distortion

- Shrinkage marks

- Internal stress

Gate Location

Proper gate design minimizes flow marks in optical areas.

Mold Surface Finish

Molds often require:

- Mirror polishing

- Micro-structuring

- Optical-grade surface treatment

8. Advantages of Optical LSR Over Traditional Optical Materials

Compared with glass and rigid plastics, Optical LSR offers several advantages:

- Impact resistance (won’t shatter like glass)

- Flexible design possibilities

- Integrated sealing & optical functions

- Superior thermal and UV resistance

- High-volume automated production

These benefits reduce assembly costs and improve product durability.

9. Typical Industries Using Optical LSR

Industries increasingly adopting Optical LSR include:

- LED lighting manufacturers

- Automotive Tier 1 suppliers

- Medical device companies

- Smart electronics brands

- Industrial optical equipment manufacturers

For OEMs, Optical LSR enables lighter, safer, and more durable optical systems.

10. How to Choose the Right Optical LSR Manufacturer

When sourcing Optical LSR injection molding services, consider the following:

- Experience with optical-grade LSR materials

- In-house precision mold manufacturing

- Cleanroom or dust-controlled molding

- Strict optical quality inspection

- Ability to support custom design and prototyping

A professional LSR manufacturer can help optimize both optical performance and production cost.

11. Conclusion

Optical Liquid Silicone Rubber is a high-performance material bridging the gap between traditional optics and flexible elastomers. With its outstanding transparency, optical stability, and injection molding efficiency, Optical LSR has become a preferred solution for modern lighting, automotive, medical, and electronic applications.

As optical systems continue to demand higher precision, durability, and design freedom, Optical LSR will play an increasingly important role in next-generation product development.