Table of Contents

ToggleIn the rapidly advancing world of precision optics, LED lighting, wearable electronics, and medical technology, the demand for high-performance materials is growing faster than ever. Among the most versatile and innovative materials leading this evolution is optical liquid silicone rubber (LSR).

But what exactly is optical liquid silicone rubber, and why is it becoming a go-to material in optical and lighting applications? This article explores everything you need to know — from its properties and advantages to its production process and real-world applications.

What Is Optical Liquid Silicone Rubber?

Optical liquid silicone rubber (LSR) is a specialized type of two-part, platinum-cured silicone elastomer that is designed to offer high transparency, clarity, and light transmission, similar to that of glass or optical-grade plastics like polycarbonate (PC). Unlike standard LSR, optical LSR is engineered specifically for applications where light control, clarity, and stability are critical.

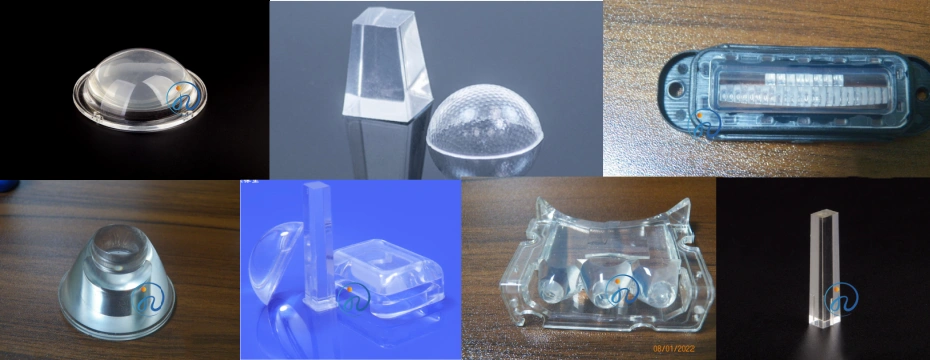

It can be injection-molded into complex shapes with tight tolerances and is often used in LED lenses, light guides, optical sensors, and medical devices.

Key Properties of Optical Liquid Silicone Rubber

Optical LSR combines the core advantages of traditional liquid silicone rubber with exceptional optical performance. Below are its defining properties:

1. High Optical Clarity

- Transmittance rates up to 94% in the visible spectrum

- Comparable to glass or optical-grade thermoplastics

- Minimal haze and low light distortion

2. High Temperature Resistance

- Withstands continuous use at -50°C to +200°C

- No yellowing or degradation over time, even under high heat

3. UV and Weather Resistance

- Excellent stability under prolonged UV exposure

- Ideal for outdoor LED or sensor applications

4. Chemical & Environmental Stability

- Resists oxidation, moisture, and common chemicals

- Long-term durability even in harsh environments

5. Flexible, Soft, and Tough

- Typical Shore A hardness range: 30A to 80A

- Excellent impact resistance and dimensional stability

6. Biocompatibility and Non-Toxicity

- Suitable for skin-contact or implant-grade medical products

- FDA, USP Class VI, and ISO 10993 compliant (depending on grade)

How Is Optical Liquid Silicone Rubber Manufactured?

Optical LSR is a two-component silicone material that is mixed in a 1:1 ratio and cured via a platinum-catalyzed addition reaction. This results in a highly pure, transparent, and cross-linked elastomer.

Processing Method:

Liquid Injection Molding (LIM) is the primary method for manufacturing optical LSR components. This process includes:

- Automated mixing and dosing of the A and B components

- Cold runner systems to minimize material waste

- Hot molds (170–200°C) to cure the part in seconds

- Cleanroom environments to avoid contamination

This process enables high-volume production of parts with complex geometries and tight tolerances — essential for optical precision.

Applications of Optical Liquid Silicone Rubber

The unique properties of optical LSR make it ideal for a wide range of optical, medical, and electronic applications, including:

1. LED Lighting Components

- Lenses, reflectors, and diffusers

- Used in automotive headlights, streetlights, flashlights, and architectural lighting

- High thermal stability ensures long LED lifespan

2. Medical Devices

- Optical-grade tubing, diagnostic lenses, surgical lighting parts

- Transparent seals and valves for visualization

- Biocompatible and sterilizable

3. Consumer Electronics

- Smartphone flash lenses, smartwatch screens, optical buttons

- Wearable devices that require skin-safe, soft-touch optics

4. Automotive Sensors

- LIDAR and camera covers for ADAS systems

- Clear, UV-resistant components that maintain clarity in extreme conditions

5. Industrial Optics

- Light guides, sensors, and inspection equipment

- Parts exposed to high heat or vibration

Optical LSR vs. Other Optical Materials

How does optical LSR compare to other transparent materials like polycarbonate, acrylic, or glass? Here’s a quick breakdown:

| Property | Optical LSR | Polycarbonate (PC) | Acrylic (PMMA) | Glass |

|---|---|---|---|---|

| Light Transmission | 92–94% | 88–90% | 90–92% | ~92% |

| Flexibility | Excellent | Low | Low | Very low |

| UV Resistance | Excellent | Poor | Moderate | Excellent |

| Heat Resistance | Up to 200°C | ~120°C | ~90°C | Up to 250°C |

| Impact Resistance | Excellent | High | Moderate | Low |

| Weight | Light | Light | Light | Heavy |

| Moldability | Complex 3D shapes | Moderate | Moderate | Low |

| Biocompatibility | High | Moderate | Low | Low |

Design Tips for Optical LSR Components

If you’re designing parts using optical liquid silicone rubber, consider the following:

- Wall Thickness: LSR flows easily; thin and thick sections can be molded in one cycle.

- Surface Finish: Polishing the mold directly impacts the final optical clarity.

- Part Geometry: Undercuts, micro-lenses, and fine details are achievable.

- Tool Venting: Proper venting prevents air traps and optical defects.

- Gating & Degassing: Cold runner and degassing strategies ensure bubble-free parts.

Challenges in Using Optical LSR (and How to Overcome Them)

| Challenge | Solution |

|---|---|

| Air bubbles in molded parts | Optimize degassing and injection speed |

| Flash formation | Ensure precise mold clamping and sealing |

| Surface contamination | Use cleanroom processing and mold maintenance |

| Adhesion to other substrates | Choose self-adhesive LSR grades or apply plasma treatment |

Future Trends in Optical LSR

As the technology advances, optical liquid silicone rubber continues to evolve. Future trends include:

- Miniaturized optical parts for wearable electronics

- Hybrid overmolding with PC or metal for smart lenses

- AI-based quality control in LIM processing

- Bio-optical LSR for implantable medical devices

Conclusion

Optical liquid silicone rubber (LSR) is a high-performance, transparent elastomer that’s redefining what’s possible in optics, lighting, and electronics. Its unique blend of optical clarity, durability, heat resistance, and moldability makes it the material of choice for engineers and designers seeking both form and function.

Whether you’re working on LED lighting systems, wearable tech, or medical instruments, understanding and leveraging the benefits of optical LSR can help you create better, longer-lasting, and more innovative products.