Table of Contents

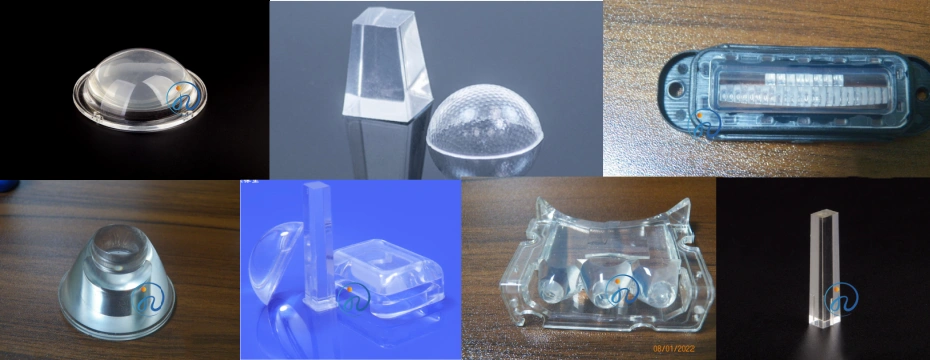

ToggleOptical Liquid Silicone Rubber is a high-purity, transparent silicone material engineered for applications requiring exceptional clarity, durability, and resistance to extreme environments. Unlike conventional silicones, Optical LSR combines the flexibility and biocompatibility of silicone with optical properties akin to glass, making it ideal for industries where precision and transparency are critical. From medical devices to automotive sensors and consumer electronics, it is revolutionizing how products are designed and manufactured.

In this article, we’ll explore the key applications of Optical LSR, its advantages over traditional materials, and emerging trends shaping its future. Whether you’re an engineer, designer, or industry professional, understanding Optical LSR’s potential can inspire innovative solutions for your projects.

What is Optical LSR?

Optical LSR is a specialized form of liquid silicone rubber formulated to offer high light transmission, minimal haze, and excellent thermal and UV stability. Its unique properties include:

- Transparency: Allows light transmission rates of over 90%, comparable to optical glass.

- Flexibility: Maintains elasticity across a wide temperature range (-40°C to 200°C).

- Biocompatibility: Safe for medical and wearable applications.

- Chemical Resistance: Withstands exposure to oils, solvents, and moisture.

These characteristics make it suitable for replacing glass or plastics in applications where weight, safety, and design flexibility are priorities.

Key Applications of Optical LSR

1. Medical Devices and Healthcare

It is widely used in medical products requiring clarity and sterilization resistance. Examples include:

- Endoscopic Components: Seals and lenses that withstand repeated autoclaving.

- Wearable Health Sensors: Transparent housings for optical heart rate monitors and pulse oximeters.

- Drug Delivery Systems: Precise tubing and connectors for infusion pumps.

Its biocompatibility ensures compliance with FDA and ISO standards, reducing risks in critical healthcare environments.

2. Automotive Lighting and Sensors

The automotive industry leverages Optical LSR for advanced lighting systems and sensors:

- LED Headlights and Taillights: Lenses and gaskets that resist yellowing from UV exposure.

- LiDAR and Camera Housings: Protective covers with minimal distortion for autonomous vehicle sensors.

- Sealing Systems: Weather-resistant seals for electronic control units (ECUs).

Optical LSR’s durability ensures performance under harsh conditions, such as temperature fluctuations and vibration.

3. Consumer Electronics

In electronics, Optical LSR enables sleek, functional designs:

- Smartwatch Lenses: Scratch-resistant covers for fitness trackers and smartwatches.

- VR/AR Headsets: Comfortable, optical-grade lenses enhancing user immersion.

- Button Seals: Water-resistant seals for smartphones and wearables.

Its lightweight nature and moldability support complex geometries, reducing assembly costs.

4. Optics and Photonics

It is ideal for precision optical components:

- Light Guides and Diffusers: Uniform light distribution in displays and signage.

- Lenses for Drones and Cameras: Lightweight alternatives to glass for aerial and action cameras.

- Fiber Optics: Protective coatings and connectors ensuring signal integrity.

Advantages of Optical LSR Over Other Materials

1. Superior Optical Performance

Unlike polycarbonate or acrylic, Optical LSR maintains clarity under UV radiation and high temperatures, preventing yellowing or cloudiness over time.

2. Design Flexibility

LSR can be injection-molded into complex shapes with tight tolerances, reducing the need for additional components or post-processing.

3. Durability and Resistance

It outperforms plastics in extreme environments, offering better tear strength, chemical resistance, and longevity.

4. Cost-Efficiency

Despite higher material costs, Optical LSR reduces total production expenses by simplifying assembly and enhancing product lifespan.

Future Trends in Optical LSR

- Miniaturization: As devices shrink, it will enable smaller, more efficient components for micro-optics and IoT devices.

- Sustainable Formulations: Bio-based and recyclable LSR variants are under development to meet eco-friendly demands.

- Integration with Smart Technologies: it will play a key role in flexible displays and wearable health tech.

Conclusion

It is a transformative material bridging the gap between silicone’s flexibility and glass-like clarity. Its applications span medical, automotive, electronics, and optics, driven by its unparalleled durability, design adaptability, and optical performance. As technology advances, It will continue enabling innovations that demand precision, reliability, and aesthetic excellence.

For industries seeking to enhance product performance, it offers a solution worth exploring. Stay ahead of trends by incorporating this material into your next project.

FAQs

- Is Optical LSR expensive?

While costlier than plastics, its durability and design efficiency often justify the investment. - Can Optical LSR be colored?

Yes, it can be tinted without significant loss of transparency. - How does Optical LSR compare to glass?

It’s lighter, shatterproof, and more design-flexible, though glass may offer slightly higher clarity.