Table of Contents

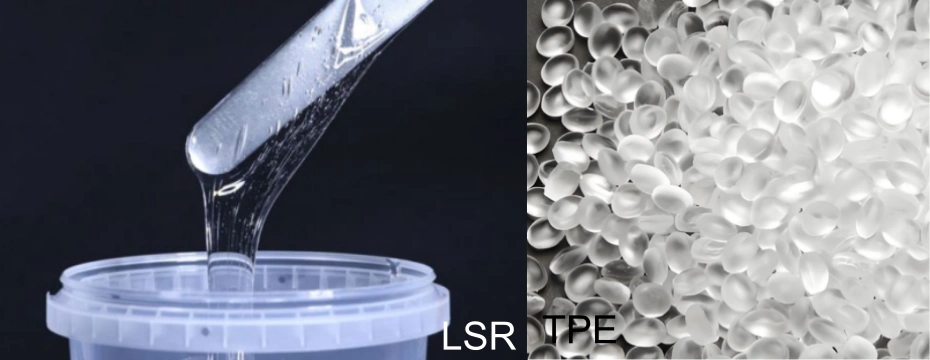

ToggleWhen selecting elastomeric materials for industrial, medical, or consumer products, LSR (Liquid Silicone Rubber) and TPE (Thermoplastic Elastomer) are two of the most commonly compared options. Although both materials offer flexibility, elasticity, and rubber-like performance, they differ significantly in chemical structure, processing methods, performance characteristics, and application suitability.

What Is LSR (Liquid Silicone Rubber)?

Liquid Silicone Rubber (LSR) is a two-part, platinum-cured silicone elastomer processed through liquid injection molding (LIM). Once cured, LSR becomes a thermoset material that does not melt again.

Key Characteristics of LSR

- Excellent thermal stability (-60°C to 200°C or higher)

- Outstanding chemical and UV resistance

- High flexibility and elastic recovery

- Biocompatibility and hypoallergenic properties

- Long service life and aging resistance

- Transparent or naturally translucent appearance

LSR is widely used in medical devices, automotive sealing systems, electronics, baby products, and food-contact components.

What Is TPE (Thermoplastic Elastomer)?

Thermoplastic Elastomers (TPEs) are a class of materials that combine rubber-like elasticity with thermoplastic processability. Unlike LSR, TPE can be melted and reshaped multiple times.

Common Types of TPE

- TPE-S (SBC-based elastomers)

- TPU (Thermoplastic Polyurethane)

- TPO (Thermoplastic Polyolefin)

- TPV (Thermoplastic Vulcanizate)

Key Characteristics of TPE

- Soft touch and flexibility

- Easy processing by injection molding or extrusion

- Recyclability

- Lower initial tooling and processing costs

- Wide range of hardness options

TPE is commonly used in consumer electronics, grips, seals, toys, footwear, and household products.

Chemical Structure: LSR vs TPE

LSR Structure

LSR is based on siloxane (Si–O–Si) polymer chains, which provide exceptional thermal and chemical stability. Once cured, the crosslinked structure cannot be re-melted.

TPE Structure

TPE consists of physical crosslinks formed by thermoplastic domains. These bonds break under heat, allowing the material to be reshaped.

Key Difference:

- LSR = Thermoset (permanent crosslinking)

- TPE = Thermoplastic (reversible bonding)

Processing Methods

LSR Processing

- Liquid Injection Molding (LIM)

- Requires precise metering and mixing of two components

- Platinum-cured system

- Automated, closed-loop production

- Higher tooling precision required

TPE Processing

- Standard injection molding

- Extrusion

- Overmolding with common thermoplastics (ABS, PP, PC)

- Easier startup and shorter cycle times

From a manufacturing perspective, TPE offers lower entry barriers, while LSR provides superior performance for demanding applications.

Temperature Resistance

LSR Temperature Performance

- Continuous use: up to 200°C

- Short-term exposure: up to 250–300°C

- Remains flexible at extremely low temperatures

TPE Temperature Performance

- Typical range: -30°C to 120°C

- Softening or deformation under high heat

Conclusion: LSR significantly outperforms TPE in high-temperature and extreme environment applications.

Chemical & Environmental Resistance

LSR offers superior resistance to:

- Oils and greases

- Acids and alkalis

- UV radiation

- Ozone

- Moisture and steam

TPE resistance varies depending on formulation, but generally degrades faster when exposed to harsh chemicals or UV light.

Biocompatibility & Safety

LSR

- Medical-grade and food-grade certifications available

- USP Class VI, ISO 10993 compliant

- Odorless, tasteless, non-toxic

- Ideal for long-term skin or body contact

TPE

- Some grades are FDA compliant

- Biocompatibility depends heavily on formulation

- Plasticizers may migrate over time

For medical and healthcare products, LSR is often the preferred material.

Design Flexibility & Overmolding

LSR Design Advantages

- Excellent flow into micro and complex geometries

- Flash-free molding with high precision

- Strong bonding with thermoplastics (LSR overmolding)

TPE Design Advantages

- Easier color matching

- Faster prototyping

- Compatible with multi-material designs

LSR is preferred for high-precision sealing and functional components, while TPE excels in ergonomic and aesthetic designs.

Cost Comparison: LSR vs TPE

LSR Costs

- Higher raw material cost

- Higher tooling investment

- Lower scrap rate

- Longer product lifespan

TPE Costs

- Lower material cost

- Lower tooling complexity

- Higher recyclability

- Suitable for high-volume consumer goods

Cost decision should be based on total lifecycle cost, not just material price.

Typical Applications

Common LSR Applications

- Medical tubing and seals

- Baby bottle nipples and pacifiers

- Automotive gaskets and connectors

- Wearable device components

- Electrical insulation parts

Common TPE Applications

- Phone cases and grips

- Shoe soles

- Soft-touch handles

- Consumer product housings

- Toys and sporting goods

LSR vs TPE: Which One Should You Choose?

Choose LSR if your product requires:

- High temperature resistance

- Long-term durability

- Medical or food safety compliance

- Chemical and UV resistance

- Precision molding

Choose TPE if your product requires:

- Lower upfront cost

- Faster production cycles

- Recyclability

- Soft-touch aesthetics

- Consumer-grade performance

Future Trends in LSR and TPE

With increasing demand for medical devices, EV components, and wearable electronics, LSR continues to grow in high-performance markets. Meanwhile, bio-based and recyclable TPE formulations are expanding in consumer applications.

Both materials will coexist, serving different performance and cost requirements.

Conclusion

While both LSR and TPE offer flexibility and elastomeric properties, their differences in chemical structure, performance, processing, and applications are substantial. LSR stands out in high-performance, safety-critical, and long-life applications, whereas TPE remains a cost-effective solution for mass-market products.

Understanding these differences ensures better material selection, optimized product performance, and reduced long-term risk.