Table of Contents

ToggleLiquid Silicone Rubber (LSR) is widely used in industries like medical, baby care, automotive, and consumer electronics. With its exceptional flexibility, thermal resistance, and biocompatibility, LSR is the material of choice for high-performance parts. But to unlock its full potential, one critical aspect must be controlled meticulously—tolerance of LSR tools.

In this article, we will explain what tolerance means in the context of LSR molding, why it matters, what influences it, and how to achieve optimal results through precision toolmaking.

1. What Does Tolerance Mean in LSR Tooling?

In manufacturing, tolerance refers to the allowable variation in a physical dimension. It defines how much deviation is permitted between the actual molded part and its intended design.

When it comes to LSR tools, tolerance directly affects:

- Final part accuracy

- Assembly compatibility

- Functionality and sealing

- Visual appearance

- Compliance with industry standards

Example:

If a baby pacifier or medical mask component has a tolerance of ±0.05 mm, any part produced must stay within 0.05 mm of the design specification. Exceeding this could lead to leakage, failure in assembly, or regulatory non-compliance.

2. Why Tolerance Is Critical in LSR Molding

Precision Requirements in Medical & Baby Products

LSR is often used in safety-critical products like CPAP masks, pacifiers, syringes, or seals. These require ultra-tight tolerances, sometimes even tighter than ±0.02 mm, to ensure reliable sealing and biocompatibility.

Material Shrinkage Compensation

LSR tends to shrink between 2% and 4% during curing. Proper tolerance calculations must account for this, or the final part may deviate significantly.

Multi-Cavity Molds Consistency

For multi-cavity LSR tools, tolerance becomes more crucial as the same precision must be replicated across all cavities. Even a small variation between cavities can result in defective parts.

Assembly with Other Materials

Many LSR parts are overmolded with plastic or metal inserts. In these cases, tolerances must match those of inserts or housing parts to avoid misalignment or failure.

3. Standard Tolerance Ranges for LSR Tools

The achievable tolerance of LSR tools depends on the part design, material behavior, and toolmaking technology. Below are typical ranges:

| Feature | Typical Tolerance |

|---|---|

| Dimensional (general) | ±0.05 mm to ±0.10 mm |

| Precision features (sealing lips) | ±0.02 mm to ±0.05 mm |

| Flash control | ≤ 0.02 mm |

| Shut-off areas | ±0.01 mm to ±0.03 mm |

| Multi-cavity consistency | ≤ ±0.02 mm |

These tolerances are tight, especially compared to thermoplastics, and require high-precision mold fabrication.

4. Factors That Affect Tolerance in LSR Tools

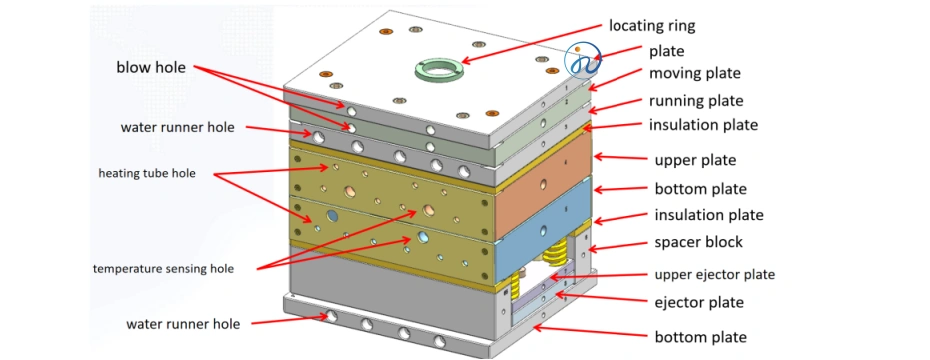

Tool Design and Build Quality

- High-grade tool steel (e.g., H13 or S136)

- Precision CNC or EDM machining

- Polished surfaces to reduce flash

- Robust venting and sealing systems

Material Shrinkage Behavior

- Each LSR grade (e.g., medical vs food grade) has different shrink rates.

- Shrinkage must be predicted and compensated in the tool design.

Injection Molding Parameters

- Injection speed, temperature, and pressure all influence how the LSR fills and cures.

- Inconsistent processing leads to dimensional variation.

Part Geometry

- Thin-walled parts are more sensitive to dimensional shift.

- Complex geometries require tighter control of flow paths.

Tool Maintenance

- Over time, wear and tear can degrade the tolerance capability.

- Regular polishing and alignment checks help maintain precision.

5. How to Control and Improve Tolerances in LSR Tooling

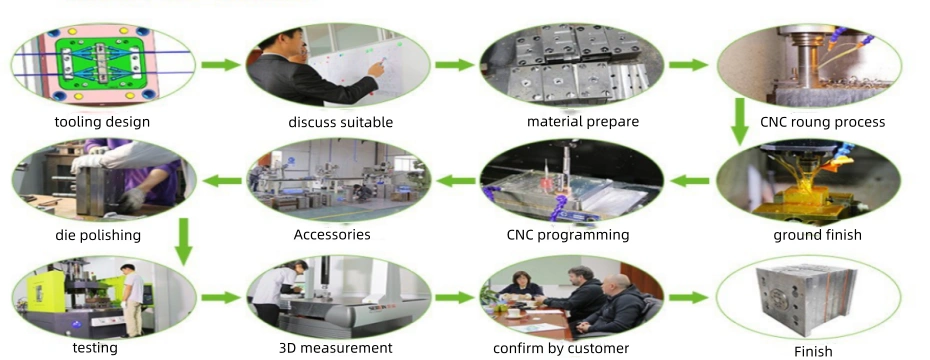

DFM (Design for Manufacturing)

- Collaborate with toolmakers during the early design stage.

- Avoid unnecessary complexity that can cause tolerance stack-up.

Use of High-Precision CNC & EDM

- Advanced toolmaking machines ensure consistency up to microns.

- EDM is preferred for intricate shut-offs and complex geometries.

Simulation Software

- Use mold flow simulation to analyze fill, shrink, and cure behavior.

- Optimize gating and venting to avoid air traps and flow hesitations.

Cavity Balancing

- Ensures equal flow and pressure to all cavities.

- Reduces inter-cavity variations in multi-cavity tools.

Steel Inserts & Interchangeable Components

- For modular tools, replaceable inserts allow tighter tolerance control.

- Great for prototyping and iteration.

6. Tolerance vs. Cost: The Trade-Off

Tighter tolerances mean:

- Higher toolmaking costs

- More time for tool design and validation

- Higher rejection rates if tolerance windows are too narrow

So, it’s essential to balance functionality, cost, and manufacturability. Use tight tolerances only where performance or regulation demands it, and relax them where feasible.

7. Case Study: LSR Baby Pacifier Mold Tool

- Requirement: ±0.03 mm dimensional tolerance

- Material: Medical-grade LSR

- Tool type: 4-cavity steel mold with hot runner

- Challenges: Thin-wall nipple and high clarity

- Solution: High-polish mold cavity, mold flow simulation, and cavity pressure sensors

- Result: >98% yield, consistent clarity and softness

8. How to Choose an LSR Tooling Partner for Tight Tolerance Projects

When selecting a manufacturer for your LSR tool, consider the following:

- Experience with medical-grade or baby-grade silicone

- In-house tool design and mold manufacturing

- Capability for CMM inspection and first-article measurement

- Expertise in LSR material science and shrinkage prediction

- Cleanroom molding availability if needed

Conclusion

In the world of LSR molding, precision starts with the tool. Tolerance is not just a technical detail—it’s a foundational element that ensures your parts function, fit, and last as expected.

From the initial tool design to the final molded part, controlling tolerance requires a strategic combination of expertise, technology, and material understanding.

Whether you are manufacturing baby care products, medical devices, or automotive seals, understanding and managing the tolerance of LSR tools is critical to success.