Table of Contents

ToggleTwo-shot injection molding is also called “2k molding” or co-injection molding. To successfully perform liquid silicone rubber two-shot molding, a specially designed co-injection molding machine is needed, and a mold builder and molder that are skilled and experienced in LSR processing to ensure accurate alignment and precision placement.

Two-shot LSR injection molding involves molding an LSR material and a second polymer in the same molding process. The second material can be either a compatible thermoplastic material or a different grade of LSR (different durometer or pigment). The two materials are molded during the same process and combined to form one integrated two-material component. This process is a two-shot injection molding process.

How Does Two-Shot Injection Molding Work?

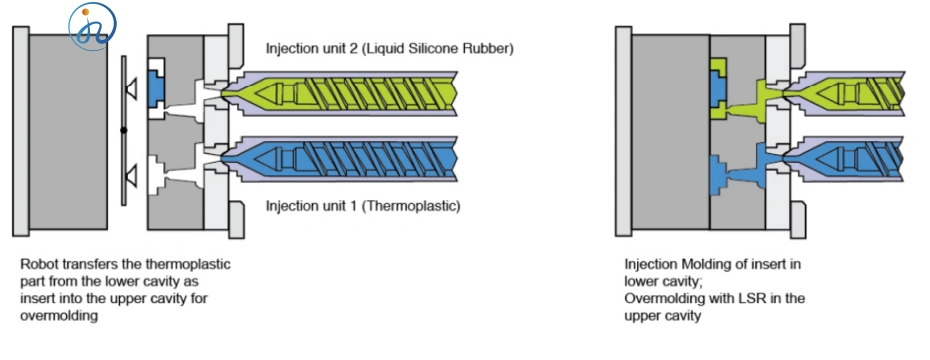

The two-shot injection molding process typically involves the following steps:

- First Shot – Base Material Injection:

The first thermoplastic material is injecting into a mold to form the base or substrate of the part. - Second Shot – Overmolding:

Once the first material has solidified, the mold either rotates or shifts to a second cavity, where a second material (often a softer or different-colored plastic) is injected over or around the first shot.

This process completes in one continuous molding cycle using a specially designed two-shot injection molding machine.

Key Advantages of Two-Shot Injection Molding

1. Enhanced Product Design

Two-shot molding enables the creation of complex parts that combine hard and soft materials, or multiple colors, in a single unit. This is particularly useful in ergonomics, branding, and functionality.

2. Improved Part Strength and Quality

Bonding two materials directly during molding results in a stronger interlock compared to post-assembly methods like gluing or mechanical fastening.

3. Lower Assembly Costs

By eliminating secondary assembly steps, manufacturers save time, labor, and cost, increasing efficiency in high-volume production.

4. Superior Sealing and Insulation

The second material, often a soft elastomer, provides excellent sealing performance in applications like medical devices, automotive gaskets, and electronics housings.

Common Applications of Two-Shot Molding

- Consumer electronics: Multi-color buttons, soft-touch grips, phone cases

- Automotive parts: Sealed connectors, handles, switches

- Medical devices: Overmolded seals, grips, diagnostic housings

- Household appliances: Control panels, knobs, handles

- Industrial components: Ergonomic tools, control devices

Materials Used in Two-Shot Injection Molding

The process typically combines a rigid thermoplastic (like PA, PC, or Nylon) with a softer Liquid silicone. The compatibility of the two materials must be carefully considering to ensure proper adhesion and performance.

Common combinations include:

- PC + Liquid Silicone Rubber (LSR)

- PA+ Liquid Silicone Rubber (LSR)

- Nylon + Liquid Silicone Rubber (LSR)

Tooling and Machine Requirements

Two-shot molding requires:

- A specialized 2-shot injection molding machine with two barrels

- A rotating mold system or core-back tool to transfer parts between shots

- Precision tooling design to ensure alignment, venting, and material compatibility

Though the initial investment in tooling is higher, the long-term return on investment is significant for medium to high-volume production.

Challenges in Two-Shot Injection Molding

While two-shot molding offers many benefits, manufacturers should be aware of:

- Tooling complexity and cost

- Material compatibility issues

- Cycle time optimization

- Machine setup and programming complexity

Working with an experienced injection molding partner can help mitigate these challenges.

Two-Shot Molding vs Overmolding: What’s the Difference?

Two-shot injection molding is a fully automated process where both shots happen in the same machine cycle.

Overmolding, on the other hand, usually refers to a manual or two-step process where a second material is molding over a previously molded part in a separate machine or operation.

| Feature | Two-Shot Molding | Overmolding |

|---|---|---|

| Cycle Time | Faster | Slower |

| Labor | Automated | Manual or semi-automated |

| Precision | High | Moderate |

| Tooling Cost | High | Lower |

Conclusion: Is Two-Shot Injection Molding Right for You?

Two-shot injection molding is ideal for companies that:

- Require multi-material or multi-color parts

- Want to reduce post-processing and assembly steps

- Need enhanced functionality, ergonomics, or sealing

Though the upfront cost is higher, the benefits of product performance, aesthetic appeal, and production efficiency make it a worthwhile investment for many applications.

If you’re considering using two-shot injection molding in your next project, consult with a specialized manufacturer to explore design feasibility, material compatibility, and tooling options.

FAQs About Two-Shot Injection Molding

Q: Can silicone be used in two-shot molding?

A: Yes, Liquid Silicone Rubber (LSR) can be overmolded onto thermoplastics using two-shot or multi-component injection molding systems.

Q: What industries use two-shot molding the most?

A: Automotive, medical, electronics, and consumer products lead in adopting this technology.

Q: Is two-shot molding more expensive than traditional molding?

A: Tooling is more costly upfront, but cost savings come from reduced assembly and improved part quality in high-volume production.