Table of Contents

ToggleLiquid Silicone Rubber (LSR) injection molding has become a core manufacturing technology for medical, automotive, electronics, baby care, and industrial sealing products. However, many buyers and product developers still ask:

What can an LSR injection molding factory service really offer beyond basic part production?

A professional LSR injection molding factory is not just a parts supplier—it is a full-service manufacturing partner that supports your project from concept to mass production. This article explains in detail what services a qualified they can provide and how these services help you reduce cost, shorten lead time, and improve product quality.

1. Design Engineering Support (DFM for LSR Injection Molding)

A reliable LSR injection molding factory service starts with engineering support and design for manufacturability (DFM).

1.1 Product Design Optimization

LSR behaves differently from thermoplastics. An experienced factory can help optimize:

- Wall thickness uniformity

- Draft angles for demolding

- Parting line locations

- Undercut feasibility

- Seal and lip geometry for medical or sealing parts

Early DFM support helps avoid costly mold revisions and reduces risk during mass production.

1.2 Material Selection Consulting

LSR injection molding factories typically provide material recommendations based on:

- Medical-grade, food-grade, or industrial-grade requirements

- Shore hardness (e.g., 10A–80A)

- Transparency, color, and UV resistance

- Biocompatibility standards such as ISO 10993, USP Class VI, or FDA compliance

Choosing the right LSR material ensures long-term performance and regulatory compliance.

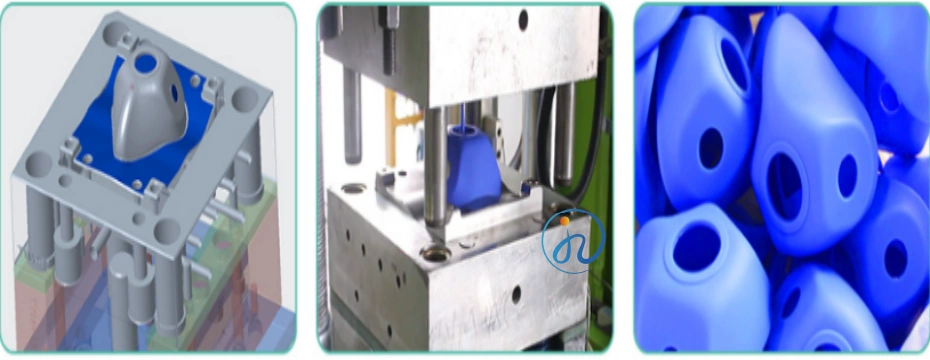

2. LSR Injection Mold Design & Tooling Service

Tooling quality determines production stability and part consistency. A professional LSR injection molding factory service includes in-house mold design and manufacturing.

2.1 Precision LSR Mold Design

LSR molds require special considerations:

- Cold runner systems

- Vacuum system integration

- Venting for air release

- High-precision cavity machining

- Temperature control channels

Factories with deep LSR experience can design molds that ensure stable injection, minimal flash, and high yield.

2.2 Rapid Tooling & Prototype Mold

For new product development, many LSR injection molding factories offer:

- Rapid prototype molds

- Low-cavity pilot molds

- Soft tooling for early testing

This service shortens product development cycles and enables faster market validation.

3. Prototyping & Sample Validation Service

Before mass production, a professional LSR injection molding factory service provides functional prototypes and samples.

3.1 Functional LSR Prototypes

Factories can produce:

- Small-batch prototype parts

- Engineering samples for testing

- Fit & function samples for assembly verification

These prototypes allow customers to test mechanical performance, sealing performance, and assembly compatibility.

3.2 Testing & Feedback Loop

An experienced factory will support multiple rounds of:

- Mold tuning

- Process parameter optimization

- Dimensional verification

This ensures your LSR product design is fully validated before scaling to volume production.

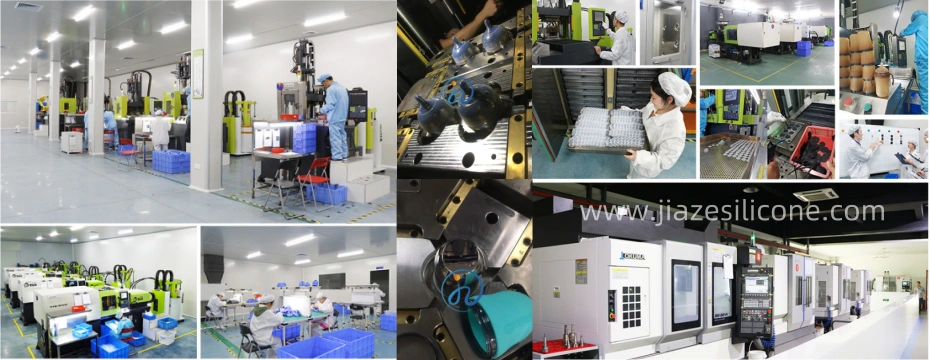

4. Mass Production LSR Injection Molding Service

At the core, their service provides stable, high-volume manufacturing capability.

4.1 Automated LSR Injection Molding

Advanced factories operate:

- Fully automated LSR injection molding machines

- Closed-loop material mixing systems

- Robotic demolding

- Automated visual inspection

Automation ensures consistent quality, high efficiency, and low defect rates, especially for medical and precision components.

4.2 High-Volume Production Capacity

Professional LSR injection molding factories can support:

- Low-volume pilot runs

- Medium-volume production

- High-volume mass production

Scalable capacity allows customers to grow from startup volumes to millions of parts annually without changing suppliers.

5. Secondary Processing & Assembly Services

5.1 Secondary Operations

These may include:

- Trimming and deflashing

- Surface treatment (plasma treatment)

- Post-curing

- Laser marking

- Printing or coating

These value-added services reduce the need for external suppliers and simplify your supply chain.

5.2 Overmolding & Multi-Material Solutions

Many LSR injection molding factories support:

- LSR overmolding on plastic or metal

- Two-shot molding (LSR + thermoplastic)

- Insert molding

This is especially important for medical devices, wearable electronics, and automotive sealing systems.

6. Quality Control & Regulatory Compliance

Quality assurance is one of the most important parts of LSR injection molding factory service.

6.1 Process Control & Inspection

Professional factories implement:

- IQC, IPQC, OQC systems

- SPC process control

- Dimensional measurement (CMM, optical inspection)

- Material traceability

These systems ensure every batch meets customer specifications.

6.2 Medical & Food-Grade Compliance

For regulated industries, factories can provide:

- ISO 13485 (medical quality system)

- ISO 9001 quality management

- Cleanroom molding environments

- Validation documentation (PPAP, FAI, IQ/OQ/PQ support)

This level of compliance is critical for medical LSR parts and food-contact silicone products.

7. Supply Chain & Project Management Support

An LSR injection molding factory service also includes project management and supply chain support.

7.1 Project Management

Dedicated project managers help:

- Coordinate tooling, sampling, and production

- Control timelines and milestones

- Communicate engineering changes

- Provide regular production updates

This improves collaboration and reduces communication risks, especially for overseas customers.

7.2 Supply Chain Integration

Factories can assist with:

- Material sourcing

- Packaging design

- Custom labeling

- Logistics coordination

This “one-stop manufacturing service” simplifies procurement and shortens lead times.

8. Cost Optimization & Manufacturing Efficiency

One of the biggest values of working with a professional LSR injection molding factory is cost optimization.

8.1 Tooling Cost Optimization

Experienced factories optimize:

- Cavity count

- Mold layout

- Runner system design

- Maintenance strategy

This reduces tooling investment while ensuring long-term production stability.

8.2 Unit Cost Reduction

Through:

- Automation

- Cycle time optimization

- Scrap rate reduction

- Lean manufacturing

Factories help lower your total cost of ownership (TCO) over the product lifecycle.

9. How to Choose the Right LSR Injection Molding Factory Service

Not all suppliers offer the same level of service. When selecting an LSR injection molding factory, consider:

- Proven experience with LSR projects

- In-house tooling capability

- Medical or food-grade compliance

- Engineering and DFM support

- Scalable production capacity

- Quality system certifications

- Transparent communication

Choosing the right partner directly impacts your product quality, regulatory success, and long-term cost control.

10. Why Partnering with a Professional LSR Injection Molding Factory Matters

A professional LSR injection molding factory service offers more than just manufacturing. It provides:

- Technical expertise

- Risk reduction

- Faster time to market

- Stable quality

- Long-term scalability

By partnering with a qualified LSR injection molding factory, you gain a strategic manufacturing partner who helps turn your design into reliable mass production.

Conclusion

So, what can an LSR injection molding factory service offer?

From design support and tooling development to automated mass production, quality control, compliance management, and supply chain integration, a professional LSR injection molding factory provides a complete, end-to-end manufacturing solution.

For brands, engineers, and product developers, choosing the right LSR injection molding partner is not just about price—it is about building a long-term, reliable manufacturing relationship that supports innovation, quality, and growth.