Table of Contents

ToggleIf you work in construction, manufacturing, chemical handling, or any industry where airborne hazards are a concern, you know the critical importance of a reliable labor mask respirator. But not all respirators are created equal. The material they are made from plays a pivotal role in their effectiveness, comfort, and longevity. Enter the liquid silicone rubber labor mask respirator—a premium choice that is revolutionizing industrial safety.

This comprehensive guide will dive deep into what a liquid silicone rubber labor mask respirator is, why its material is a game-changer, and how it compares to other options on the market. By the end, you’ll understand exactly why this type of respirator is worth the investment for anyone serious about respiratory protection.

What is a Labor Mask Respirator?

Before we focus on the material, let’s clarify the device itself. A labor mask respirator (also known as a reusable respirator or half-mask respirator) is a personal protective equipment (PPE) device designed to protect the wearer from inhaling hazardous substances. These can include:

- Dust, mists, and fumes

- Gases and vapors

- Biological particulates

Unlike disposable masks, a reusable labor mask respirator consists of a facepiece (the mask itself) and replaceable filter cartridges or filters. The facepiece forms a seal on the user’s face, ensuring that all inhaled air is forced through the filters, which trap the dangerous contaminants. The effectiveness of this seal is the single most important factor in the respirator’s performance.

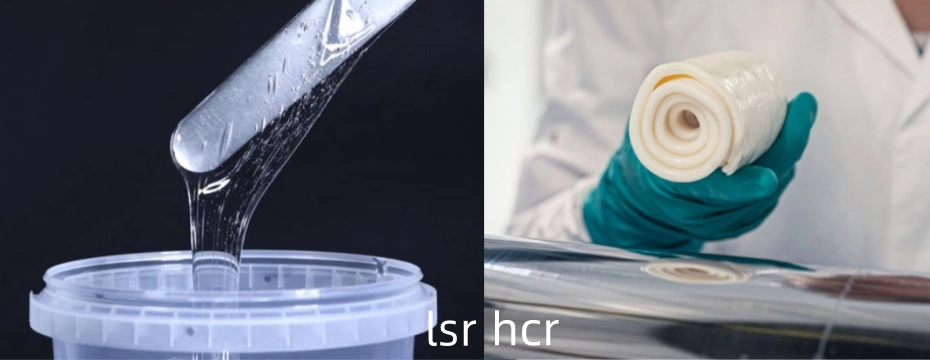

What is Liquid Silicone Rubber (LSR)?

To understand why a liquid silicone rubber labor mask respirator is superior, we must first understand the material.

Liquid Silicone Rubber (LSR) is a high-purity, platinum-cured elastomer known for its exceptional properties. It is created through a liquid injection molding process (LIM), which allows for the production of complex, high-precision, and consistent parts. Key characteristics of LSR include:

- Hypoallergenic: LSR is biologically inert, meaning it is non-toxic and highly unlikely to cause skin irritation or allergic reactions—a common issue with rubber or latex-based respirators.

- Excellent Temperature Resistance: LSR performs consistently in extreme temperatures, from as low as -60°C (-76°F) to over 200°C (392°F). It won’t become brittle in the cold or degrade quickly in the heat.

- Superior Flexibility and Tear Strength: Despite its softness, LSR is incredibly durable and resistant to tearing, ensuring the respirator maintains its integrity over time.

- Easy to Clean: The non-porous surface of LSR makes it easy to disinfect and clean, which is crucial for reusable safety equipment.

Why Choose a Liquid Silicone Rubber Labor Mask Respirator?

Now, let’s apply these material properties directly to the function of a labor mask respirator. The benefits are significant and directly impact the wearer’s safety and comfort.

1. Unmatched Comfort for Long-Term Wear

The primary advantage of a liquid silicone rubber labor mask respirator is comfort. Industrial shifts are long, and a respirator that causes discomfort will be adjusted, fidgeted with, or even removed—compromising safety.

- Soft and Skin-Friendly: LSR is significantly softer and more pliable than traditional thermoplastics or silicone rubbers. It conforms gently to the contours of the face without applying excessive pressure.

- Reduced Pressure Points: This softness eliminates red marks and pressure sores on the bridge of the nose and cheeks, which are common complaints with harder masks.

2. A Superior, Reliable Seal

As mentioned, the seal is everything. A liquid silicone rubber labor mask respirator excels here because of the material’s inherent properties.

- Perfect Conformation: The flexibility of LSR allows the sealing flange (the part that touches your face) to create a perfect, airtight seal against a wide variety of facial structures, even those with beards or scars.

- Consistency in Movement: The seal remains effective even when the user talks, moves their head, or bends over. The material moves with the skin, rather than pulling away from it.

3. Exceptional Durability and Longevity

A respirator is an investment. A liquid silicone rubber labor mask respirator is built to last, providing a better return on investment over time.

- Resistant to Ozone and UV Light: Unlike many elastomers, LSR does not crack or degrade when exposed to sunlight or ozone, common in outdoor work environments.

- Chemical Resistance: It holds up well against many chemicals, sweat, and cleaning agents, preventing the mask from breaking down.

- Withstands Repeated Sterilization: For industries requiring high levels of hygiene (like pharmaceuticals or food processing), LSR can withstand repeated autoclaving or chemical disinfection without losing its properties.

4. Hypoallergenic and Odorless

For workers with sensitive skin, a liquid silicone rubber labor mask respirator is a blessing. It contains no latex or plasticizers that can cause dermatitis. Furthermore, LSR is naturally odorless, unlike some rubber masks that can have a strong, unpleasant smell that causes headaches.

Liquid Silicone Rubber vs. Other Respirator Materials

How does an LSR mask stack up against the competition?

- LSR vs. Thermoplastic (e.g., Polypropylene): Thermoplastic respirators are often cheaper but are rigid and less comfortable. They can crack in cold temperatures and may not form as reliable a seal. LSR is the clear winner in comfort and seal.

- LSR vs. General Silicone Rubber: While traditional silicone is good, LSR is a higher-grade material. The injection molding process for LSR creates a more consistent product with fewer impurities. LSR is typically softer and more durable than its general silicone counterpart.

- LSR vs. Neoprene/Natural Rubber: These materials are more prone to causing allergic reactions, can degrade with exposure to ozone, and often have a strong chemical odor. LSR is hypoallergenic, odorless, and more chemically stable.

Key Considerations When Choosing Your LSR Respirator

Not all liquid silicone rubber labor mask respirators are identical. When selecting one, consider:

- NIOSH Approval: In the United States, ensure the respirator is NIOSH-approved (e.g., N95, P100). This certification guarantees it has been tested to provide the stated level of protection.

- Compatible Filters: Choose a model that offers a wide range of filter cartridges for the specific hazards you face (e.g., particulate filters, organic vapor cartridges).

- Size and Fit: Most manufacturers offer small, medium, and large sizes. A proper fit-test is essential for maximum safety.

- Exhalation Valve: An exhalation valve reduces heat and moisture buildup inside the mask, making it much more comfortable to wear for extended periods.

Conclusion: Is a Liquid Silicone Rubber Labor Mask Respirator Right for You?

The liquid silicone rubber labor mask respirator represents the pinnacle of reusable respiratory protection. While it may come with a higher upfront cost than a basic thermoplastic model, the investment is justified by its unparalleled comfort, superior seal, and remarkable durability.

For workers who rely on their labor mask respirator day in and day out, the benefits are not just a luxury—they are a necessity. A comfortable respirator is a respirator that is worn correctly and consistently. By choosing a model made from advanced Liquid Silicone Rubber, you are not only investing in a piece of safety equipment but also in your own health, comfort, and long-term well-being on the job. It is the smart, safe, and comfortable choice for the modern professional.