Table of Contents

ToggleIn recent years, LSR injection molding service has become a preferred manufacturing solution for industries requiring high-precision, high-purity, and high-performance silicone parts. From medical devices and baby care products to automotive seals and consumer electronics, liquid silicone rubber (LSR) offers unique material advantages that traditional rubber and thermoplastics cannot match.

This article provides a complete explanation of what LSR injection molding service is, how it works, its advantages, applications, costs, and how to select a reliable LSR molding partner.

What Is LSR Injection Molding Service?

It refers to a professional manufacturing service that produces silicone parts using liquid silicone rubber through an automated injection molding process.

LSR is a two-part platinum-cured silicone elastomer supplied in liquid form. During molding, the two components are precisely mixed, injected into a heated mold, and cured rapidly to form finished silicone parts.

Unlike solid silicone compression molding, LSR injection molding is:

- Fully automated

- Highly repeatable

- Suitable for mass production

- Ideal for complex, tight-tolerance designs

What Is Liquid Silicone Rubber (LSR)?

Liquid Silicone Rubber is a high-purity elastomer known for:

- Excellent elasticity

- Biocompatibility

- Thermal stability

- Chemical resistance

Key Properties of LSR

- Temperature resistance: -60°C to +200°C

- Shore hardness range: 10A – 80A

- Odorless, tasteless, non-toxic

- UV and aging resistance

- Electrical insulation properties

Because of these characteristics, LSR is used in medical, food-contact, and high-performance industrial applications.

How Does LSR Injection Molding Service Work?

Step 1: Material Feeding & Metering

LSR consists of Part A and Part B, stored separately. A precision dosing system pumps both components in a 1:1 ratio.

Step 2: Mixing

The materials are mixed dynamically with pigments or additives (if required) to ensure consistent color and properties.

Step 3: Injection into Heated Mold

Unlike thermoplastics, LSR is injected into a heated mold (typically 160–200°C) through a cold runner system to prevent premature curing.

Step 4: Vulcanization (Curing)

The heat triggers rapid platinum-catalyzed curing, forming a flexible and durable silicone part.

Step 5: Demolding & Post-Processing

Finished parts are automatically demolded. Optional processes include:

- Flash trimming

- Post-curing

- Surface treatment

- Assembly or overmolding

Types of LSR Injection Molding Services

1. Custom LSR Injection Molding

Tailored solutions based on customer drawings, samples, or specifications.

2. Medical-Grade LSR Molding

ISO 13485 compliant production for medical and healthcare products.

3. Food-Grade Silicone Molding

FDA / LFGB compliant parts for baby and kitchen products.

4. LSR Overmolding Service

LSR bonded with plastic, metal, or other substrates.

5. High-Volume LSR Production

Automated systems for stable, large-scale manufacturing.

Advantages of LSR Injection Molding Service

1. High Precision & Tight Tolerances

LSR molding supports intricate geometries with consistent dimensions.

2. Excellent Material Performance

- Long service life

- Elastic recovery

- Resistance to extreme environments

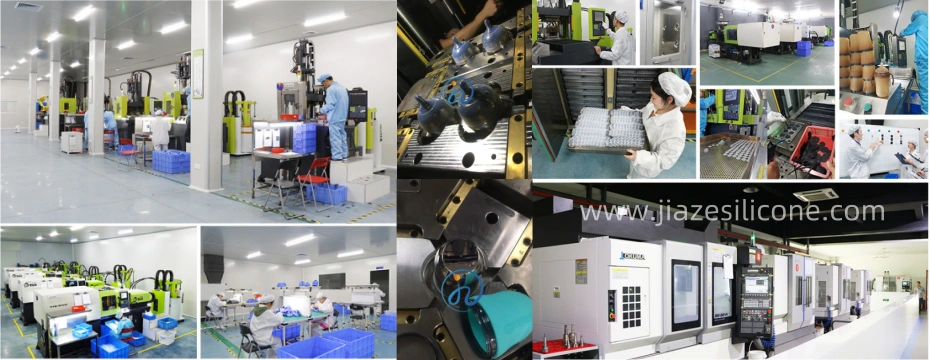

3. Clean & Automated Production

Ideal for cleanroom manufacturing and sensitive applications.

4. Reduced Labor Cost

Automation minimizes manual handling and defects.

5. Scalability

From prototyping to millions of parts annually.

Common Applications of LSR Injection Molding Service

Medical & Healthcare

- Respirator masks

- Seals and valves

- Catheters

- Medical connectors

Baby & Food Products

- Baby bottle nipples

- Pacifiers

- Baking molds

- Kitchen utensils

Automotive

- Gaskets

- O-rings

- Connector seals

- Sensor covers

Consumer Electronics

- Waterproof seals

- Keypads

- Wearable device components

Industrial Applications

- Insulation components

- High-temperature seals

- Chemical-resistant parts

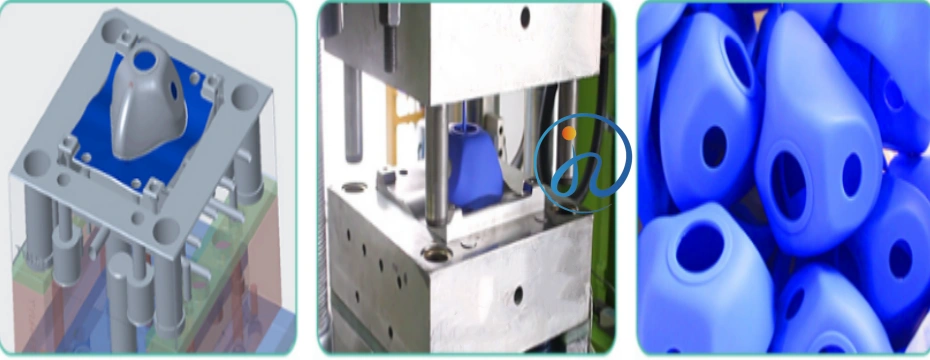

LSR Injection Molding Tooling & Mold Design

Mold Characteristics

- Hardened steel molds

- Cold runner systems

- Venting for air release

- Multi-cavity designs

Tooling Cost Factors

- Part complexity

- Number of cavities

- Mold steel type

- Runner system

Although tooling cost is higher than compression molds, unit cost decreases significantly in mass production.

Quality Control in LSR Injection Molding Service

Professional LSR manufacturers typically implement:

- Incoming material inspection

- In-process dimensional checks

- Visual and functional testing

- Traceability systems

- ISO 9001 / ISO 13485 standards

How Much Does LSR Injection Molding Service Cost?

Cost Elements

- Mold tooling cost (one-time)

- Raw material cost

- Machine time

- Labor & quality control

- Secondary processing

Typical Cost Advantages

- Lower scrap rate

- Consistent part quality

- Reduced long-term cost

For high-volume projects, LSR injection molding offers excellent cost-performance balance.

How to Choose the Right LSR Injection Molding Service Provider

Key Evaluation Factors

- Experience with LSR projects

- In-house mold making capability

- Quality certifications

- Material sourcing

- Engineering support

- Communication & lead time

A reliable partner should support you from design review to mass production.

Why Choose a Professional LSR Injection Molding Service?

Working with an experienced LSR manufacturer ensures:

- Faster development cycles

- Stable quality

- Regulatory compliance

- Long-term supply reliability

This is especially critical for medical, baby, and high-performance applications.

Conclusion

LSR injection molding service is a highly efficient, precise, and scalable manufacturing solution for modern silicone products. With its superior material properties, automation advantages, and broad application range, LSR molding continues to replace traditional rubber processes across industries.

Choosing the right LSR injection molding partner can significantly impact your product quality, cost, and time-to-market.