Table of Contents

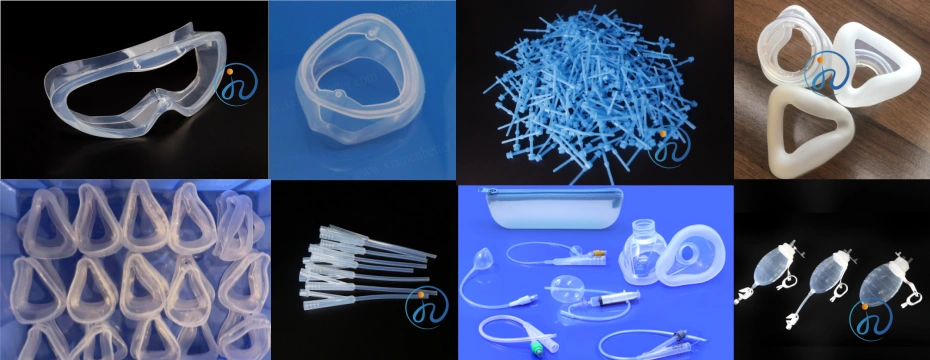

ToggleThe medical industry is defined by an uncompromising pursuit of innovation, safety, and reliability. Every component, from a massive imaging machine to the smallest implantable seal, must perform flawlessly under extreme conditions. This relentless drive for perfection has made material science a cornerstone of medical device manufacturing. Among the plethora of materials available, one has consistently proven itself to be exceptionally well-suited for critical applications: Liquid Silicone Rubber (LSR).

But what exactly is the advantage of LSR that makes it so indispensable to the medical industry? This article delves into the key advantages of LSR and why it has become the material of choice for life-saving and life-enhancing medical devices.

Key Advantage 1: Unmatched Biocompatibility and Safety

This is arguably the most critical advantage of LSR in the medical industry. Biocompatibility refers to a material’s ability to perform with an appropriate host response when applying to the human body, without causing toxic, injurious, or immunological reactions.

- Inherently Hypoallergenic: LSR is biologically inert. It does not leach plasticizers or additives, a common issue with many thermoplastics and latex. This eliminates risks of skin irritation, allergic reactions, or complications within the body.

- Regulatory Compliance: High-grade medical LSR are formulating to meet rigorous international standards such as USP Class VI, ISO 10993, and FDA regulations. This pre-certification streamlines the device approval process, a significant advantage for manufacturers.

- Applications: This makes LSR ideal for both short-term and long-term implantable devices like pacemaker leads, cochlear implants, hydrocephalus shunts, and various drug-delivery systems, as well as non-implantable skin-contact devices.

Key Advantage 2: Superior Resistance to Sterilization Methods

Medical devices must be sterilizing repeatedly and aggressively to prevent healthcare-associated infections (HAIs). Few materials can withstand the harshness of modern sterilization techniques as well as LSR.

- Autoclaving (Steam Sterilization): LSR excels in moist heat environments, maintaining its physical properties and integrity through hundreds of autoclave cycles at temperatures exceeding 120°C (248°F).

- Gamma and E-Beam Radiation: LSR is highly resistant to the degradation that radiation can cause in other polymers, which often become brittle and fail.

- Applications: Reusable devices like breathing masks, respiratory tubes, surgical tools, and endoscope components are almost exclusively made from or sealed with LSR due to this durability.

Key Advantage 3: Excellent Thermal Stability and Flexibility

The performance of a medical device cannot fluctuate with temperature. LSR maintains its flexibility and mechanical properties across an incredibly wide temperature spectrum, from -60°C to over 200°C (-76°F to 392°F).

- Cold Flexibility: It remains supple and elastic in cold storage, preventing seals from cracking.

- Applications: This is vital for components that transition from cold storage to a warm operating room, for seals in thermal treatment devices, and for components in diagnostic equipment that generate heat.

Key Advantage 4: Precision and Complexity in Manufacturing

The liquid injection molding (LIM) process used for LSR is a significant boon for the medical industry, which demands micro-precision and complex geometries.

- High Detail Replication: The low viscosity of liquid silicone allows it to fill intricate mold cavities, capturing incredibly fine details and producing parts with tight, consistent tolerances.

- Applications: Catheters, micro-fluidic chips for lab-on-a-chip devices, complex seals and gaskets, and miniature connectors for fluid management systems.

Key Advantage 5: Durability, Tear Strength, and Longevity

Medical devices are subject to significant mechanical stress. LSR offers an excellent balance of softness and strength.

- High Tear Strength: Medical-grade LSR formulations are designing to resist tearing and puncturing. It is crucial for thin-walled components like balloon catheters and inflatable cuffs.

- Long-Term Stability: LSR does not weather, ozone, or UV degrade significantly. Implantable devices made from LSR are designed to last for decades inside the human body without breaking down.

- Applications: Tubing, balloon catheters, implantable devices, and external prosthetics that require durability alongside flexibility.

Key Advantage 6: Optical Clarity and Aesthetic Properties

For many devices, visibility is non-negotiable.

- Color Coding: It can be easily and permanently colored with non-migrating pigments. This is extensively used for color-coding different device functions, sizes, or connections. It reduces the risk of user error in fast-paced medical environments.

- Applications: Respiratory masks, transparent tubing, fluid connectors, and inspection seals.

The Future of LSR in the Medical Industry

The role of LSR is only expanding. As the medical industry moves towards minimally invasive surgery, personalized medicine, and smarter connected devices, the demands on materials will grow. LSR is at the forefront of this innovation, enabling:

- Advanced Drug Delivery: Sophisticated implantable pumps and valves.

- Wearable Health Monitors: Comfortable, skin-safe sensors for continuous patient monitoring.

- Combination Devices: Integrating electronics and silicone for “smart” implants.

Conclusion: The Clear Choice for Medical Innovation

So, what’s the ultimate advantage of LSR in the medical industry? It is not a single property but a powerful synergy of them all.

LSR provides a unique trifecta: unparalleled patient safety through biocompatibility. It is unwavering device reliability through sterilization resistance, and limitless design freedom through precision manufacturing.