Table of Contents

ToggleLiquid Silicone Rubber (LSR) injection molding has become one of the most advanced manufacturing technologies for producing high-precision silicone parts. From baby care products and medical devices to automotive seals and consumer goods, LSR injection moulds play a critical role in ensuring product consistency, durability, and cost-effectiveness.

One of the most important aspects of an LSR mold is its cavity design. Understanding what cavity means, how it is structured, and why it matters can help engineers, buyers, and procurement managers make smarter decisions when sourcing custom silicone parts.

What Is the Cavity of an LSR Injection Mould?

In the context of injection molding, the cavity refers to the hollow space within a mold where liquid silicone rubber is injected and cured to form a specific part.

When liquid silicone is fed into the mold through the injection system, it fills the cavity, takes its shape, and solidifies under heat and pressure. The cavity essentially acts as a blueprint of the final silicone product.

For example, if a company produces LSR baby pacifiers, the cavity inside the mould determines the shape, size, and surface quality of each pacifier. The higher the precision of the cavity, the better the final product will be.

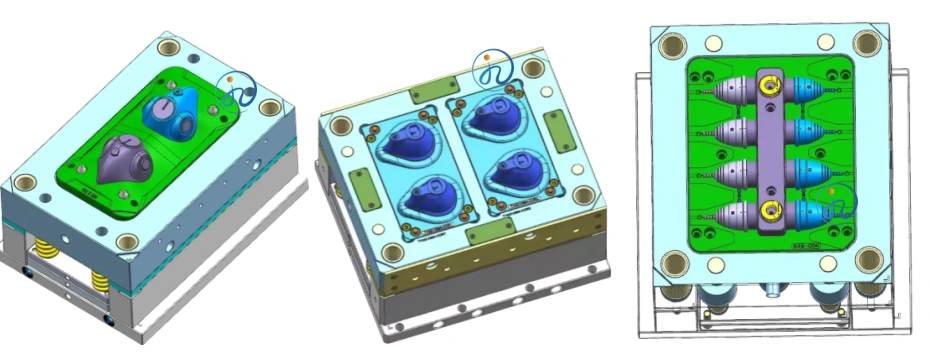

Single-Cavity vs Multi-Cavity LSR Injection Moulds

The number of cavities in an LSR injection mould directly impacts production efficiency and costs.

1. Single-Cavity Moulds

- Definition: A mould with only one cavity, producing one part per cycle.

- Advantages:

- High precision and dimensional accuracy

- Ideal for prototypes or low-volume runs

- Easier to control and maintain

- Limitations:

- Low production efficiency

- Higher cost per part

2. Multi-Cavity Moulds

- Definition: A mould with multiple cavities, producing several identical parts per cycle.

- Advantages:

- High efficiency and faster production

- Reduced cost per unit

- Consistent quality across large batches

- Limitations:

- Higher tooling cost

- More complex to design and maintain

- Risk of imbalanced filling if not designed correctly

For example, a 4-cavity LSR injection mould produces four parts per cycle, while an 8-cavity mould doubles that capacity. For mass production, multi-cavity moulds are the most cost-effective choice.

Why Cavity Design Matters in LSR Injection Moulds

Cavity design is not just about the number of cavities—it affects every aspect of production:

- Cycle Time – More cavities reduce cycle time per part, improving overall efficiency.

- Production Cost – Although multi-cavity moulds require higher initial investment, they lower per-unit cost in large-scale production.

- Quality Control – Properly designed cavities ensure uniform filling, curing, and product dimensions.

- Material Efficiency – Balanced cavity design reduces waste of LSR material.

- Scalability – Companies can start with single-cavity moulds for prototyping and upgrade to multi-cavity moulds for mass production.

Factors to Consider When Choosing the Cavity of LSR Injection Moulds

When deciding the cavity number and design for an LSR mould, several factors should be taken into account:

- Product Size – Larger products typically require single-cavity moulds due to space limitations.

- Production Volume – High-volume orders benefit from multi-cavity moulds.

- Material Flow – The design must ensure even silicone flow into all cavities.

- Tolerance Requirements – Medical and automotive parts often need high precision, making cavity balance critical.

- Tooling Budget – Multi-cavity moulds involve higher initial costs but reduce long-term expenses.

- Cycle Time Goals – Faster turnaround may require higher cavity counts.

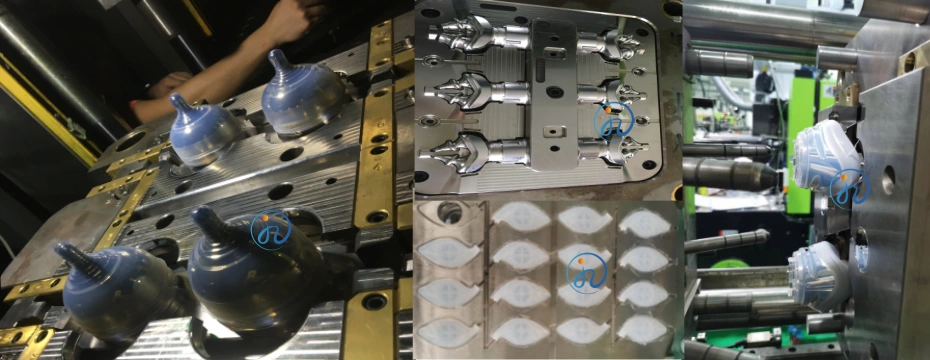

Applications of Different Cavity Designs

- Medical Devices

- Single-cavity moulds for prototypes or clinical testing

- Multi-cavity moulds for mass production of silicone nasal masks, catheters, or valves

- Baby Care Products

- Pacifiers, bottle nipples, and teething toys often use multi-cavity moulds to meet large demand

- Consumer Electronics

- Single- or dual-cavity moulds for precision components like gaskets and buttons

- Automotive Industry

- Multi-cavity moulds for seals, connectors, and vibration dampers

Best Practices for LSR Injection Mould Cavities

- Work with experienced LSR mould manufacturers to ensure cavity balance.

- Use cold runner systems for better material efficiency.

- Apply simulation software to optimize cavity filling before production.

- Regularly inspect and maintain mould cavities to avoid defects.

- Consider scalability—start with fewer cavities and expand as demand grows.

Conclusion

The cavity of an LSR injection mould is the heart of silicone product manufacturing. Whether you choose a single-cavity mould for prototypes or a multi-cavity mould for high-volume production, understanding cavity design is essential for achieving the right balance of quality, cost, and efficiency.

By working with professional LSR moulding manufacturers, companies can optimize their production processes, ensure consistent product performance, and reduce overall costs.

If you are sourcing LSR injection moulds, carefully evaluate your production needs, budget, and long-term goals before deciding on the cavity design.