Table of Contents

TogglePC overmolded liquid silicone is a widely used combination in high-performance applications, especially in consumer electronics, medical devices, baby products, automotive parts, and wearables. This process involves injecting liquid silicone rubber (LSR) over a polycarbonate (PC) substrate to form a multi-material component with both structural rigidity and soft-touch comfort.

But what does it cost to produce such components?

This article offers a detailed breakdown of the costs involved in manufacturing PC overmold liquid silicone parts. From material selection and tooling investment to processing complexity and volume pricing, we’ll analyze the key factors that influence the overall price — helping engineers, purchasers, and OEMs make better sourcing decisions.

1. What Is PC Overmolded Liquid Silicone?

Before we dive into costs, let’s define what we’re talking about.

PC overmold LSR refers to a two-component injection molded part where the rigid base (typically polycarbonate) is first formed, and then a second layer of liquid silicone rubber is injected over specific areas — usually for sealing, cushioning, grip, or comfort.

Typical applications include:

- Baby feeding bottles (PC+LSR nipples or handles)

- Smartwatch straps and housings

- Medical device enclosures

- Waterproof electronic buttons

- Automotive control knobs and gaskets

2. Factors That Determine the Cost of PC Overmolded Liquid Silicone

1. Material Costs

Polycarbonate (PC):

- Average Price: $2.5 – $5.0 per kg

- Grades: Optical, flame-retardant, impact-resistant

- Considerations: PC must withstand LSR overmolding temperatures (~170°C)

Liquid Silicone Rubber (LSR):

- Average Price: $8 – $20 per kg

- Medical or food-grade LSR is more expensive than industrial-grade

- Key Suppliers: Dow, Wacker, Momentive, Elkem

Note: The LSR portion is usually lower in volume than PC, but its unit cost is higher.

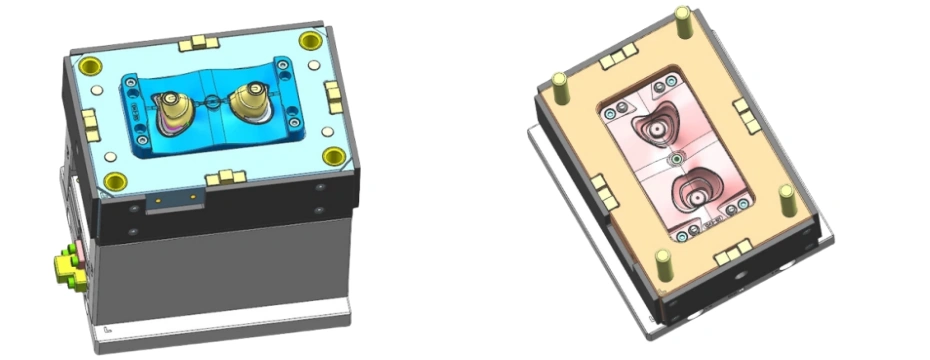

2. Tooling (Mold) Costs

Mold fabrication for two-shot or overmolding is significantly more complex than single-shot injection molding.

Cost Factors:

- Two-cavity or rotary tools

- Hot runner systems for LSR

- Precision alignment for dual-material interface

- Mold steel quality (P20, H13, S136)

Estimated Tooling Costs:

- Simple 2-cavity overmold tool: $15,000 – $30,000

- Complex multi-cavity mold: $40,000 – $100,000+

3. Production Costs

Machine and Labor

- Injection Molding Press Setup: Typically requires two machines or one with rotary/transfer tooling

- Cycle Time: 30 – 90 seconds depending on part size and wall thickness

- Labor Cost: Operators, QC staff, mold technicians

Overmolding Process Complexity:

- PC part must be pre-heated or conditioned

- LSR injection must ensure perfect bonding to PC

- Flash control is critical to avoid post-processing

Average Production Cost Estimate:

- Small parts (10,000 pcs+): $0.3 – $1.2 per part

- Medium parts (5,000 pcs): $1.5 – $3.0 per part

- Low-volume (<1,000 pcs): $3.5 – $6.0 per part

4. Secondary Operations

Depending on the application, there may be additional costs such as:

- Trimming flash manually or via vision-guided systems

- Plasma or primer surface treatment for bonding

- Printing, laser marking, or assembly

Estimated Add-on Costs:

- Post-curing (optional): $0.10 – $0.30 per part

- Surface treatment: $0.20 – $0.50 per part

- Custom branding (e.g., logos): $0.05 – $0.50 per part

3. Total Cost Structure: Example Breakdown

Let’s take an example of a smartwatch band part made from PC and overmolded with LSR:

| Cost Element | Estimated Cost (Per Part, 10K pcs run) |

|---|---|

| PC Raw Material | $0.10 – $0.20 |

| LSR Raw Material | $0.25 – $0.60 |

| Injection Molding (PC + LSR) | $0.40 – $0.80 |

| Trimming + Surface Treatment | $0.10 – $0.30 |

| Tooling Amortization (10K) | $0.30 – $0.70 |

| Total Estimated Cost | $1.15 – $2.60 per part |

For higher volumes (100K+), the per-part cost can drop to $0.80 – $1.50 depending on complexity.

4. How Volume Affects Pricing

| Order Quantity | Approx. Unit Cost |

|---|---|

| 1,000 pcs | $3.0 – $6.0 |

| 10,000 pcs | $1.2 – $2.5 |

| 100,000+ pcs | $0.8 – $1.5 |

Key Insight: Tooling cost spread is a major driver in reducing per-unit cost at scale. Larger production runs also improve machine efficiency and reduce raw material loss.

5. How to Reduce the Cost of PC Overmold LSR Production

Here are practical ways to optimize your cost:

- Design for Manufacturability (DFM): Minimize undercuts, simplify shapes

- Use standardized PC inserts: Avoid custom base components

- Select cost-efficient LSR grade: Industrial vs. medical vs. food grade

- Choose an experienced LSR molder: Better yields, faster cycle times

- Optimize mold cavitation: More cavities = lower per-part cost

- Negotiate long-term supply contracts to amortize tooling and secure material pricing

6. Choosing the Right Manufacturer

When sourcing PC overmold LSR components, ensure your supplier offers:

- Cleanroom or medical-grade production if needed

- ISO 9001 / ISO 13485 certified facilities

- In-house mold design and tooling capabilities

- Experience with both PC and LSR bonding

A manufacturer experienced in dual-material molding can save both cost and time in the long run by reducing defects and speeding up production.

7. Applications Driving Demand for PC Overmolded LSR

- Medical Devices: Seals, gaskets, masks, wearable sensors

- Consumer Electronics: Remote control buttons, smartwatch bands

- Baby Products: Bottle nipples, grips, handles

- Automotive Interiors: Knobs, seals, infotainment interface components

- Industrial Controls: Waterproof control panels, grips

Each of these applications demands high consistency, biocompatibility, and reliable sealing — all of which LSR over PC enables efficiently.

Conclusion

The cost of PC overmold liquid silicone parts depends on several key factors — materials, mold complexity, production volume, and required certifications. While upfront tooling and materials can be expensive, the long-term advantages of LSR overmolding — such as superior product performance, durability, and user comfort — make it an attractive investment for many industries.

To ensure cost efficiency, it’s crucial to work with a trusted manufacturer who understands the intricacies of both PC and liquid silicone materials, and who can guide you through the design and production optimization process.