Table of Contents

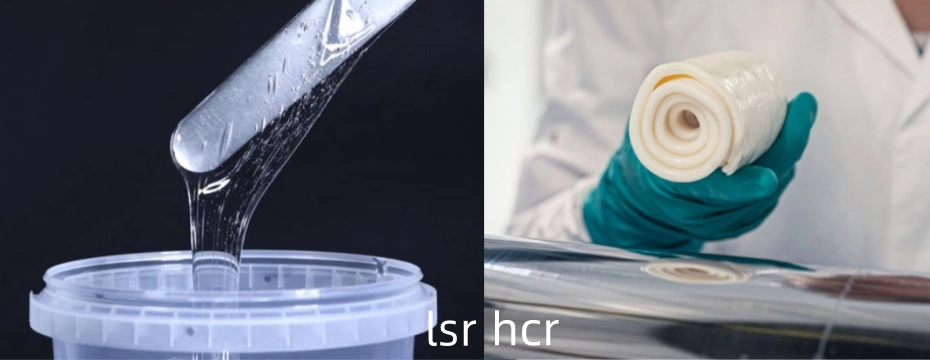

ToggleElasticity is a fundamental property that defines how materials respond to stress and strain, and when it comes to versatile, high-performance materials, silicone rubber’s elasticity stands out. Liquid Silicone Rubber (LSR) is a two-part, platinum-cured elastomer known for its exceptional flexibility, durability, and resistance to extreme conditions. But what exactly gives LSR its remarkable elastic properties, and why is it a preferred material across industries like medical, automotive, and consumer goods?

In this in-depth guide, we’ll explore the science behind silicone rubber’s elasticity, its key characteristics, how it compares to other materials, and its real-world applications. Whether you’re an engineer, product designer, or someone curious about material science, this article will provide valuable insights into why silicone rubber’s elasticity is critical for innovation and performance.

1. Understanding Elasticity in Silicone Rubber

Elasticity refers to a material’s ability to deform under stress (e.g., stretching or compression) and return to its original shape once the stress is removed. In the case of silicone rubber, this property is due to its unique polymer structure.

LSR consists of long-chain polymers with alternating silicon and oxygen atoms, creating a flexible backbone. These chains are cross-linked during the curing process, forming a three-dimensional network. When force is applied, the chains stretch and reorient, but the cross-links ensure they spring back once the force is released. This structure is what gives silicone rubber’s elasticity its high recovery rate and reliability.

2. Key Factors Influencing Silicone Rubber’s Elasticity

Several factors determine the degree and performance of silicone rubber’s elasticity:

A. Polymer Structure and Cross-Linking

The silicon-oxygen bonds in LSR are highly flexible, allowing the material to withstand repeated stretching without permanent deformation. The cross-link density—controlled during manufacturing—affects elasticity: higher cross-linking results in a stiffer material, while lower cross-linking enhances flexibility.

B. Temperature Resistance

Unlike many elastomers, silicone rubber maintains its elasticity across a wide temperature range (-50°C to 200°C). This thermal stability makes it ideal for applications in extreme environments, such as automotive engine components or medical sterilization equipment.

C. Durability and Tear Strength

It is complemented by its high tear strength and resistance to fatigue. This means LSR can endure repeated stretching, compression, and bending without cracking or losing its elastic properties.

D. Chemical and UV Resistance

LSR is inert to many chemicals, oils, and UV radiation, which helps preserve its elasticity over time. This makes it suitable for outdoor applications and medical devices exposed to harsh disinfectants.

3. How Silicone Rubber’s Elasticity Compares to Other Materials

When compared to materials like natural rubber, thermoplastic elastomers (TPE), or polyurethane, silicone rubber’s elasticity offers distinct advantages:

- Natural Rubber: While highly elastic, natural rubber degrades quickly under UV exposure, ozone, and temperature fluctuations. Silicone rubber outperforms it in longevity and environmental resistance.

- TPE: TPEs are flexible but often lack the thermal stability and recovery rate of LSR. Silicone rubber returns to its original shape more reliably after deformation.

- Polyurethane: Polyurethane is tough and abrasion-resistant but can harden over time. Silicone rubber remains flexible and elastic throughout its lifespan.

4. Applications Leveraging Silicone Rubber’s Elasticity

The unique elastic properties of LSR make it invaluable in various industries:

A. Medical Devices

From respiratory masks to catheter tubes, silicone rubber’s elasticity ensures a secure fit, patient comfort, and the ability to withstand repeated sterilization cycles.

B. Automotive Components

LSR is used in gaskets, seals, and vibration-damping parts. Its elasticity helps maintain a tight seal under vibration and thermal expansion, reducing the risk of leaks.

C. Consumer Electronics

Waterproof seals in smartwatches, phone cases, and keyboards rely on silicone rubber’s elasticity to absorb shocks and resist wear.

D. Baby Products

Bottle nipples, pacifiers, and teething toys benefit from LSR’s soft, hypoallergenic, and elastic nature, ensuring safety and durability.

5. Benefits of Silicone Rubber’s Elasticity in Product Design

- Longevity: Products made with LSR last longer due to their resistance to fatigue and environmental factors.

- Precision: LSR can be injection-molded into complex shapes with tight tolerances, retaining elasticity in intricate designs.

- Safety: Its biocompatibility and stability make it safe for medical and food-grade applications.

- Cost-Effectiveness: Reduced replacement frequency and maintenance costs due to its durability.

6. Testing and Measuring

Elasticity is typically measured through:

- Tensile Tests: Determine elongation at break and modulus of elasticity.

- Compression Set Tests: Assess the material’s ability to recover after compression.

- Cyclic Fatigue Tests: Evaluate performance under repeated stress.

LSR often achieves elongation rates of 400% to 700%, with a compression set of less than 10%—indicating excellent elastic recovery.

7. Future Trends: Innovations in Silicone Rubber Elasticity

Advancements in LSR formulations are enhancing silicone rubber’s elasticity further:

- Self-Healing LSR: Materials that repair minor tears or cuts autonomously.

- Conductive LSR: Elastic silicone with embedded conductivity for wearable tech.

- Eco-Friendly Formulations: Sustainable LSR variants without compromising elasticity.

Conclusion

Silicone rubber’s elasticity is more than just a physical property—it’s a cornerstone of modern material science, enabling innovations across healthcare, automotive, electronics, and beyond. Its ability to combine flexibility with durability, temperature resistance, and safety makes LSR an unparalleled choice for demanding applications.

As technology evolves, so will the capabilities of Liquid Silicone Rubber, solidifying its role as a critical material for the future. Whether you’re designing a life-saving medical device or a everyday consumer product, understanding silicone rubber’s elasticity is key to unlocking its full potential.