Table of Contents

ToggleBefore diving into the numbers, it’s essential to understand why LSR tooling cost is a specialized and significant investment. LSR injection molding is a unique process. The material is a two-part liquid that cures with heat. This requires a mold that can:

- Handle Liquid Feedstock: Utilize a cold runner system to keep the material liquid before it enters the mold cavity.

- Withstand High Temperatures: Operate at temperatures around 180-220°C (356-428°F) for curing.

- Facilitate Complex Geometry: Often include complex actions like sliding lifts, cores, and hot runner needles to create undercuts and intricate parts.

The tool itself is the heart of the process, and its quality directly dictates the quality of your final parts, your production efficiency, and your long-term total cost of ownership.

The 7 Key Factors Driving Your LSR Tooling Cost

Let’s dissect the core elements that will determine the final price of your LSR mold.

1. Part Design and Complexity

This is the most significant driver. A simple, gasket-like part requires a simple mold. Complexity adds cost exponentially.

- Undercuts: Features that prevent the part from being ejected straight out of the mold require additional mechanisms like sliding side-actions or lifter pins. Each action adds complexity, machining time, and cost.

- Wall Thickness: While LSR is great for consistent wall thickness, very thick sections can require longer cure times, potentially necessitating a larger tool to maintain production output.

- Tolerances: Tight, medical-grade tolerances demand higher precision in machining, better materials, and more extensive quality control, all of which increase cost.

- Surface Finish: A mirror-polished finish (common for medical parts) is far more labor-intensive and expensive than a standard textured finish.

2. Mold Material Selection (Tool Steel)

The choice of steel is a balance between durability, performance, and cost.

- Pre-Hardened Steels (e.g., P20): A lower-cost option suitable for low-to-medium volume production or prototype tools. Less resistant to wear and corrosion.

- Hardened Stainless Steels (e.g., S136): The standard for most production LSR molds. They offer excellent wear resistance and high corrosion resistance, which is crucial because LSR can produce acidic by-products during curing. While more expensive upfront, they provide a much longer tool life.

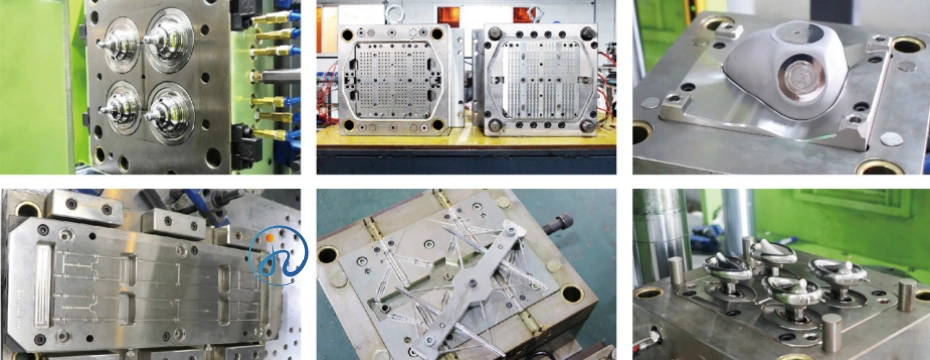

3. Number of Cavities

How many parts do you want to produce per molding cycle?

- Single Cavity: Lowest tooling cost, ideal for prototyping and very low-volume production.

- Multi-Cavity: Increases the initial tooling cost significantly (more machining, more components) but drastically reduces the per-part cost at high volumes. The decision is a classic trade-off between upfront investment and long-term piece-part price.

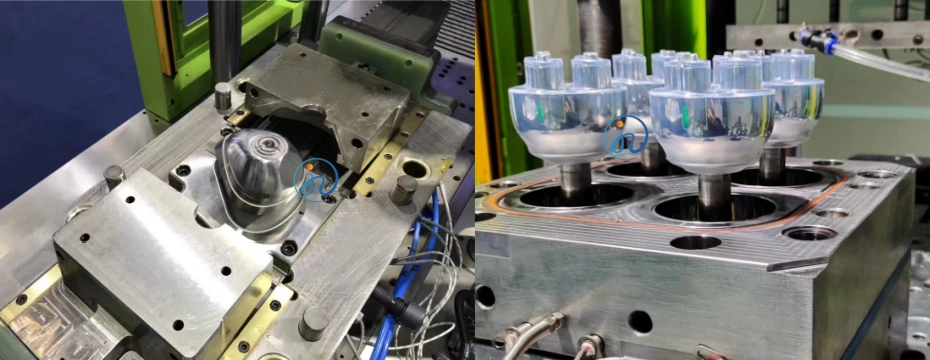

4. Cold Runner System vs. Hot Runner System

LSR molds use “cold” runners, but the technology here is a major cost factor.

- Standard Cold Runner Block: A simple, machined block that creates runners which are wasted material (scrap). Lower initial cost but higher material waste over time.

- Hot Runner System (or “Temperature Controlled”): This system actively cools the runner to keep the LSR liquid. While it has a higher initial cost, it eliminates material waste, which is a huge saving given the price of medical-grade LSR. It also improves cycle times and part quality. The decision hinges on your production volume and material cost.

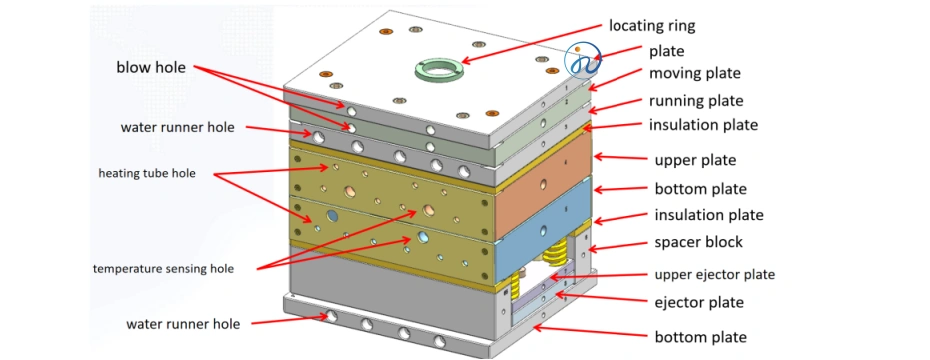

5. Mold Base Size and Complexity

The physical size and construction of the mold base itself contribute to the cost.

- Size: A larger mold for a bigger part requires more steel and larger machining equipment.

- Complexity: A mold with multiple side-actions, lifters, and intricate cooling channels requires more design time, precision machining, and assembly labor.

6. Cooling System Design

Efficient cooling is vital for achieving fast cycle times. A well-designed cooling system with conformal channels that follow the part’s contour ensures uniform and rapid cooling. This requires more advanced design (often using 3D printing for the cooling lines) and machining, adding to the initial cost but paying for itself in higher production throughput.

7. Supplier Expertise and Location

Not all mold makers are created equal. A supplier with deep expertise in LSR-specific challenges (like venting, shrinkage, and material flow) may charge a premium, but they will deliver a higher-quality, more robust tool that performs reliably for years. Similarly, tooling shops in North America or Western Europe typically have higher labor rates than those in Asia, but this may be offset by advantages in communication, IP protection, and logistics.

LSR vs. Thermoplastic Tooling: A Cost Comparison

Many people ask if LSR tooling is more expensive than thermoplastic tooling. Generally, yes, LSR tooling is often 20-30% more expensive for a comparable part. Here’s why:

- Higher Grade Materials: The need for corrosion-resistant stainless steel adds cost.

- Cold Runner Systems: These are more complex than the hot runner systems often used for thermoplastics.

- Tighter Tolerances: LSR has low shrinkage, but the tools must be built to extremely precise tolerances to handle the low-viscosity liquid and prevent flash.

- Venting Requirements: LSR molds require intricate venting to allow air to escape, as the liquid material fills even the smallest gaps.

Strategies to Reduce and Optimize Your LSR Tooling Cost

You have significant control over the final cost through smart design and planning.

- Engage Early with Your Molder: Involve your LSR molding partner during the design phase (Design for Manufacturability or DFM). Their input can help you simplify geometry and avoid expensive tooling features.

- Simplify the Design: Challenge every undercut and tight tolerance. Can the design be modified to allow for straight-pull ejection?

- Start with a Single Cavity: For initial production, a single-cavity mold is cheaper. You can always invest in a multi-cavity mold later when volumes justify it.

- Choose the Right Steel: Don’t over-specify. For a proven design with expected long-term volume, H13 steel is worth it. For a prototype or low-volume part, P20 might be a cost-effective choice.

- Analyze the Runner System: For high-volume production, a hot runner system’s material savings will quickly justify its higher initial cost. Run the numbers.

Conclusion: It’s an Investment, Not Just a Cost

Viewing LSR tooling as a mere expense is a short-sighted approach. A well-designed, properly built mold is a capital investment that pays dividends through reliable production, high part quality, low scrap rates, and minimal downtime.

Instead of asking, “What’s the LSR tooling cost?” the better question is, “What is the value of a high-performance LSR tool that ensures my product’s success?”

By understanding the factors outlined in this guide and collaborating closely with an experienced LSR molder, you can make informed decisions that optimize your upfront investment while securing a reliable and cost-effective manufacturing process for the life of your product.

Ready to get a precise quote for your LSR tooling project? Contact a reputable LSR injection molder today and provide them with your 3D CAD model for a detailed DFM and cost analysis.