Table of Contents

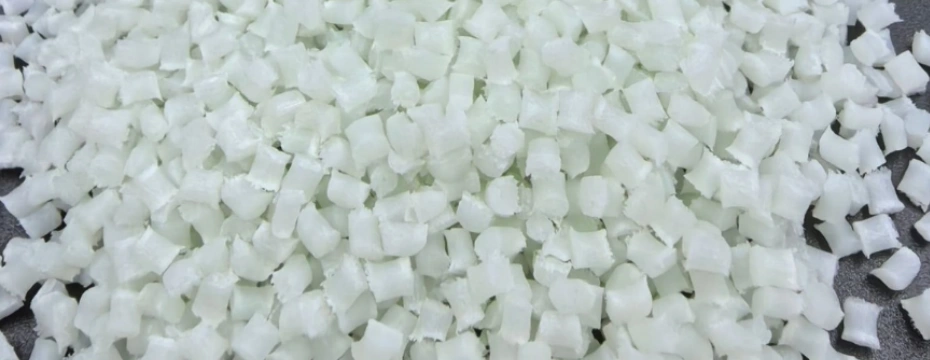

ToggleIn the world of advanced plastics and elastomers, PA66 overmolding LSR has emerged as a highly reliable solution for manufacturing high-performance components. PA66 (Polyamide 66, commonly known as Nylon 66) is a widely used thermoplastic with excellent strength, heat resistance, and wear properties. Liquid Silicone Rubber (LSR), on the other hand, is a flexible, biocompatible, and durable elastomer.

When combined through the overmolding process, PA66 and LSR form a robust hybrid structure that benefits from the strengths of both materials. This technology is increasingly using in automotive, medical, and electronic applications where mechanical strength, sealing, and long-term stability are critical.

This article explores what PA66 overmolding LSR is, how the process works, its advantages, challenges, and industrial applications.

1. Understanding the Materials: PA66 and LSR

PA66 (Polyamide 66)

- High mechanical strength and stiffness

- Excellent wear resistance and dimensional stability

- High melting point (around 260°C)

- Good resistance to oils, fuels, and chemicals

- Commonly used in automotive engine parts, gears, connectors, and electrical housings

Liquid Silicone Rubber (LSR)

- Flexible, elastic, and biocompatible

- Wide temperature range (-50°C to +250°C)

- Excellent sealing and insulating properties

- Resistant to aging, UV, and chemicals

- Commonly used in medical devices, baby products, gaskets, and wearable electronics

By combining rigid PA66 with flexible LSR, manufacturers create parts that offer strength, precision, and soft-touch sealing all in one component.

2. What is Overmolding?

Overmolding is a multi-step molding process where one material is molded over another to form a composite part.

In PA66 overmolding LSR, the PA66 is usually molded first as the rigid substrate. Then, liquid silicone rubber is injected over or around it to form a strong mechanical or chemical bond.

Benefits of Overmolding

- Reduced assembly steps (no need for adhesives or secondary joining)

- Improved design flexibility

- Strong and permanent bonding between dissimilar materials

- Enhanced product aesthetics and ergonomics

3. The PA66 Overmolding LSR Process

The process involves several key steps:

- Preparation of PA66 substrate

- The PA66 component is molding first via injection molding.

- Surface treatment may be applied to improve adhesion (plasma treatment, priming, or texturing).

- Placement in overmolding mold

- The PA66 substrate is positioned inside a second mold designed for LSR injection.

- Liquid Silicone Injection

- LSR is injected in liquid form at low viscosity.

- It flows around or into specific areas of the PA66 substrate.

- Curing and Bonding

- LSR cures inside the mold at high temperature (160°C – 200°C).

- The chemical or mechanical bond is formed between PA66 and LSR.

- Final Part Ejection

- Once cured, the hybrid PA66 + LSR part is ejected and ready for use.

4. Adhesion Between PA66 and LSR

One of the most critical aspects of PA66 overmolding LSR is the adhesion mechanism. Without proper bonding, the two materials can separate under stress.

Adhesion Methods:

- Chemical Adhesion: Special LSR grades are formulating to bond directly with PA66 during curing.

- Mechanical Interlocking: Mold design may include undercuts, grooves, or holes to lock the LSR onto PA66.

- Surface Treatment: Plasma, corona, or primers may enhance adhesion strength.

5. Advantages of PA66 Overmolding LSR

- Strength + Flexibility: PA66 provides rigidity, while LSR ensures flexibility and sealing.

- High Temperature Resistance: Both materials withstand extreme temperatures.

- Lightweight: Ideal for replacing metal components in automotive and electronics.

- Durability: Resistant to chemicals, oils, and environmental aging.

- Design Integration: Allows multiple functions (rigid structure + soft sealing) in one part.

- Biocompatibility: Suitable for medical devices requiring safe skin contact.

6. Applications of PA66 Overmolding LSR

This hybrid technology is widely used across industries:

Automotive Industry

- Sealing gaskets in engine compartments

- Vibration dampening components

- Connectors and housings with sealing rings

- Sensor covers and protective housings

Medical Industry

- Respirator masks and CPAP components

- Surgical instrument grips

- Fluid handling connectors

- Wearable healthcare devices

Electronics and Electrical

- Waterproof connectors

- Switches and keypads

- Cable assemblies with strain relief

- Insulating components

Consumer Products

- Power tool grips

- Sports equipment

- Household appliance seals

7. Challenges in PA66 Overmolding LSR

Despite its advantages, manufacturers face several challenges:

- Adhesion Issues: Not all PA66 grades bond well with LSR. Adhesion promoters or specialized grades may be needed.

- Moisture Sensitivity: PA66 absorbs moisture, which can affect molding quality. Proper drying is requiring.

- Shrinkage and Warpage: PA66 may deform during the second molding step. Mold design must compensate for this.

- Cost: LSR materials and tooling can be more expensive than conventional plastics.

- Processing Complexity: Requires precise control of injection molding parameters.

8. Design Considerations for Engineers

When designing a part with PA66 overmolding LSR, engineers should consider:

- Bonding surface area: Increase contact zones for stronger adhesion

- Mold design: Include interlocking features to prevent separation

- Material grades: Choose PA66 and LSR formulations optimized for adhesion

- Wall thickness: Maintain consistent thickness to avoid uneven curing

- Processing conditions: Optimize temperature, pressure, and curing cycle

9. Future of PA66 Overmolding LSR

With growing demand for lightweight, durable, and multifunctional parts, PA66 overmolding LSR is expecting to expand further in:

- Electric vehicles (EVs): Battery sealing and connectors

- Medical wearables: Biocompatible, ergonomic devices

- Smart electronics: Waterproof, dustproof enclosures

- Sustainable solutions: Combining recyclable PA66 grades with eco-friendly LSR formulations

Conclusion

PA66 overmolding LSR is a cutting-edge manufacturing process that brings together the mechanical strength of Polyamide 66 and the flexibility of Liquid Silicone Rubber. By integrating these materials into one part, manufacturers reduce assembly, improve product durability, and achieve higher performance.

Although challenges like adhesion and processing complexity exist, with proper material selection and mold design, this technology offers significant benefits for industries ranging from automotive to medical devices.

For engineers and procurement specialists, understanding the fundamentals of PA66 overmolding LSR can help in choosing the right solution for high-performance applications.