Table of Contents

ToggleWhat’s transparent of liquid silicone rubber part? This question is more nuancing than it appears. While many materials can be made clear, achieving true optical clarity, consistency, and durability in Liquid Silicone Rubber molded parts is a specialized feat of material science and precision manufacturing. This comprehensive guide delves into everything you need to know about transparency in LSR, from the science behind it to its practical applications and design considerations.

Understanding the Basics: What is Liquid Silicone Rubber?

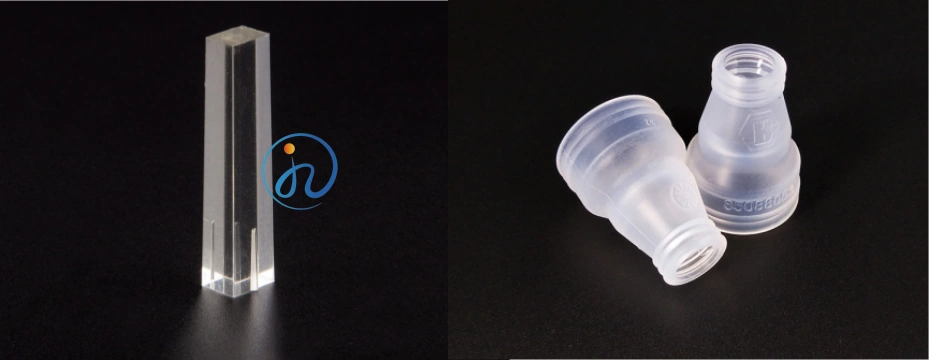

Unlike solid silicone rubber, LSR is a two-part, platinum-cured system (Part A and Part B) that is liquid at room temperature. It is injected into a heated mold where it vulcanizes (cures) into a solid, flexible elastomer. This process, known as Liquid Injection Molding (LIM), allows for the high-volume production of complex, high-precision, and consistent parts.

The Science of Clarity: How is Transparent LSR Achieved?

Achieving transparency in any material is fundamentally about controlling how light passes through it. For a silicone rubber molded part to be transparent, it must meet two critical criteria:

- Minimized Light Scattering: The material’s internal structure must be homogeneous. Any inconsistencies, such as crystalline regions, impurities, or air bubbles, will scatter light, making the material appear cloudy or opaque.

- Minimized Light Absorption: The polymer chains must allow light photons to pass through with minimal absorption within the visible light spectrum.

Standard LSR compounds are inherently translucent or opaque due to filler materials (like fumed silica) that reinforce the silicone. To create transparent LSR, manufacturers use:

- Ultra-Pure Base Polymers: Raw materials with exceptionally high purity.

- Specialized Fillers: Certain fillers with a refractive index that closely matches that of the silicone polymer, or significantly reducing filler content altogether.

- Precision Platinum Curing: The platinum-cure system ensures a clean, thorough, and uniform cross-linking reaction without producing by-products that could cause cloudiness.

Key Characteristics and Benefits of Transparent Silicone Rubber Molded Parts

Choosing a transparent silicone rubber molded part isn’t just about aesthetics; it offers significant functional advantages.

1. Optical Clarity for Monitoring and Inspection

This is the most obvious benefit. Transparent LSR parts are essential in applications where visual monitoring of fluid flow, particle presence, or internal components is critical. Think of sight glasses, flow meters, or diagnostic device windows.

2. Excellent Biocompatibility and Safety

High-purity, transparent LSR grades often meet stringent USP Class VI, ISO 10993, and FDA compliance standards. This makes them ideal for medical and food-grade applications, such as tubing, seals for transparent autoclaves, and baby care product components. The transparency allows for easy inspection of cleanliness and integrity.

3. Inherent Flexibility and Durability

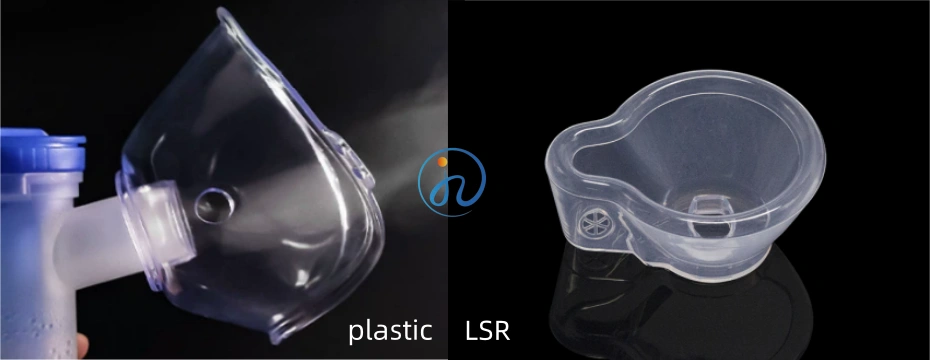

Like all LSR, transparent variants maintain excellent elasticity, tear strength, and resistance to compression set. They outperform many rigid transparent plastics in applications requiring repeated flexing or sealing under pressure.

4. Superior Thermal and UV Stability

Transparent LSR can withstand extreme temperatures (typically from -60°C to 200°C) without yellowing or degrading. Certain formulations are also UV-stable, making them suitable for outdoor applications or devices using UV light for sterilization.

5. Chemical Inertness

These parts are resistant to water, oxidation, and many chemicals, ensuring long-term stability and clarity even in harsh environments.

Common Applications of Transparent LSR Molded Parts

The unique properties of transparent LSR make it indispensable across various industries:

- Medical & Healthcare: Respiratory masks, catheter tubes, IV components, pump diaphragms, laboratory gaskets, and housings for diagnostic equipment.

- Automotive: Transparent seals for LED headlights (allowing light transmission while providing a seal), fluid level indicators.

- Consumer Electronics: Water-resistant seals for smartwatches and phones, protective covers for sensors.

- Food & Beverage: Tubing for liquid transfer, sight glasses, seals for transparent processing equipment.

- Industrial: Windows in machinery for process monitoring, gaskets for chemical processing equipment.

Design and Manufacturing Considerations for Clear LSR Parts

Achieving perfect clarity requires careful attention to the entire manufacturing process.

Material Selection

Work closely with your LSR supplier to select the right transparent grade for your application. Considerations include:

- Hardness (Shore A): Typically ranges from 10 to 50 for transparent grades.

- Refractive Index: Important for optical applications.

- Regulatory Certifications: Ensure the material has the necessary biocompatibility or food-contact certifications.

Mold Design and Surface Finish

The mold surface finish is arguably the most critical factor for clarity. The surface of the molded part is a direct replica of the mold surface.

- Polished Molds: A highly polished (mirror-finish) mold cavity is essential to produce a optically clear surface. Any tooling marks will be transferred to the part, causing light scattering.

- Venting: Proper venting is crucial to prevent air traps, which manifest as visible bubbles or burns in the final part.

The Molding Process (LIM)

Precision is key in the Liquid Injection Molding process:

- Mixing Ratio: The two-part LSR system must be mixed with extreme precision to avoid curing inconsistencies.

- Injection Speed and Pressure: Optimized to fill the mold completely and quickly without introducing air bubbles.

- Curing Temperature and Time: Must be perfectly controlled to ensure complete vulcanization without degrading the material.

Transparent LSR vs. Other Clear Elastomers

How does transparent LSR stack up against the competition?

- vs. PVC: LSR is superior in terms of temperature resistance, biocompatibility, and plasticizer-free stability (won’t become brittle over time).

- vs. Polyurethane (PU): LSR offers better heat resistance and long-term hydrolytic stability (resistance to water degradation).

- vs. Transparent Thermoplastic Elastomers (TPEs): LSR provides much better heat resistance and chemical resistance.

Conclusion: Is a Transparent Silicone Rubber Part Right for You?

The transparency of a Liquid Silicone Rubber molded part is a testament to advanced material engineering and precision manufacturing. It combines the unique benefits of silicone—biocompatibility, flexibility, and extreme temperature resistance—with the critical function of optical clarity.

When your application demands a material that can be sterilized, flexed, exposed to harsh conditions, and allow for visual inspection, transparent LSR is often the unrivaled solution. Success hinges on partnering with an experienced LSR molder who understands the intricacies of material selection, mold design, and process control to deliver the crystal-clear, high-performance parts you need.