Table of Contents

ToggleMedical mask devices play a critical role in protecting healthcare workers, patients, and the public from airborne contaminants, pathogens, and hazardous particles. From half-mask respirators and CPAP masks to anesthesia masks and protective medical face masks, material selection directly impacts safety, comfort, durability, and regulatory compliance.

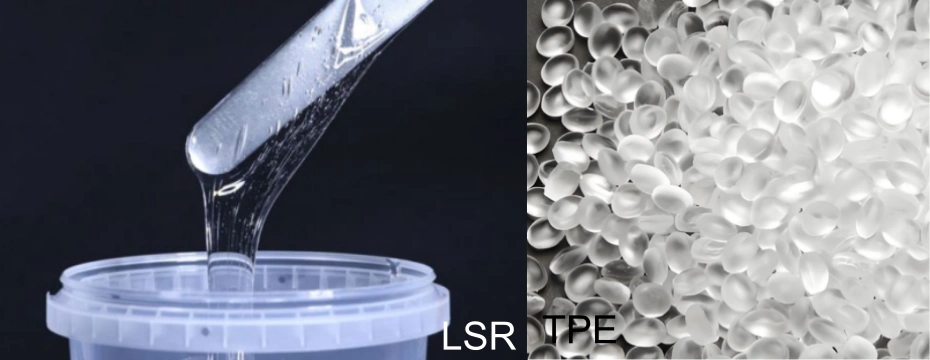

Among all elastomeric materials available today, Liquid Silicone Rubber (LSR) has become the preferred material for high-performance medical mask devices. Its combination of biocompatibility, flexibility, chemical resistance, and precision moldability makes it uniquely suited for medical and respiratory applications.

What Is Liquid Silicone Rubber (LSR)?

Liquid Silicone Rubber (LSR) is a two-part platinum-cured elastomer processed by LSR injection molding. Unlike solid silicone rubber or thermoplastics, LSR is supplied in liquid form and cured rapidly inside a heated mold.

Key characteristics of LSR include:

- High purity and low extractables

- Excellent elasticity and tear resistance

- Wide operating temperature range

- Superior chemical and UV resistance

These properties make LSR particularly suitable for medical and healthcare devices that require direct skin contact.

Why Material Selection Matters for Medical Mask Devices

Medical mask devices must meet strict functional and regulatory requirements, including:

- Skin safety and biocompatibility

- Long-term wearing comfort

- Airtight sealing performance

- Resistance to repeated sterilization

- Durability under harsh conditions

- Compliance with medical standards (FDA, ISO, USP)

Traditional materials such as TPE, PVC, latex, or rubber often fall short in one or more of these areas. Liquid silicone rubber addresses these challenges comprehensively.

Key Reasons to Choose Liquid Silicone Rubber for Medical Mask Devices

1. Excellent Biocompatibility and Skin Safety

One of the most important reasons to choose LSR for medical mask devices is its outstanding biocompatibility.

- Is latex-free, reducing allergy risks

- Contains no plasticizers or phthalates

- Meets ISO 10993 and USP Class VI standards

- Is approved for long-term skin contact

This makes LSR ideal for masks worn for extended periods, such as respirators used by healthcare professionals.

2. Superior Comfort for Long-Term Wear

Comfort is critical for user compliance. Liquid silicone rubber provides:

- Soft, skin-like touch

- High elasticity and flexibility

- Low compression set

- No pressure points on the face

LSR conforms naturally to different facial contours, making it ideal for:

- Half-mask respirators

- Full-face medical masks

- CPAP and oxygen masks

Compared with harder plastics or TPE materials, LSR significantly reduces facial fatigue and skin irritation.

3. Outstanding Sealing Performance

An effective medical mask device must provide an airtight seal without discomfort.

LSR excels in sealing applications because it offers:

- High elastic recovery

- Excellent tear resistance

- Stable sealing force over time

LSR maintains its shape and sealing performance even after repeated use, ensuring consistent protection against airborne contaminants.

4. Resistance to Sterilization and Chemicals

Medical masks are frequently exposed to:

- Steam sterilization

- Ethylene oxide (EtO)

- Gamma radiation

- Alcohol and disinfectants

Liquid silicone rubber resists:

- Heat up to 200–250°C

- UV and ozone exposure

- Chemicals, oils, and cleaning agents

This ensures long service life and stable performance, even in demanding medical environments.

5. Precision Manufacturing with LSR Injection Molding

LSR injection molding offers unmatched precision for medical mask components.

Advantages include:

- High-precision molding of thin walls and complex geometries

- Automated, closed-loop production

- Minimal material waste

- Excellent repeatability and consistency

This is especially important for:

- Mask sealing lips

- Soft contact edges

- Integrated valves and membranes

LSR injection molding also supports high-volume production, making it cost-effective for large medical programs.

6. Odorless, Tasteless, and Non-Toxic

Medical mask devices often sit close to the mouth and nose. LSR is:

- Odorless

- Tasteless

- Non-toxic

This improves the overall user experience and is critical for respiratory and anesthesia masks where patient comfort and safety are paramount.

7. Wide Temperature Stability

Liquid silicone rubber performs reliably in extreme conditions:

- Low temperatures down to −60°C

- High temperatures up to 200°C or more

This stability ensures that medical masks maintain flexibility and sealing performance during:

- Cold storage

- Transportation

- Sterilization cycles

Common Medical Mask Applications Using LSR

Liquid silicone rubber is widely used in the following medical mask devices:

- Half-mask respirators

- Full-face respirators

- CPAP and BiPAP masks

- Anesthesia masks

- Oxygen delivery masks

- Protective medical face masks

- Pediatric and neonatal masks

Its versatility allows designers to optimize comfort, safety, and durability in one material.

LSR vs Other Materials for Medical Masks

| Property | LSR | TPE | PVC | Latex |

|---|---|---|---|---|

| Biocompatibility | Excellent | Good | Moderate | Allergy Risk |

| Comfort | Excellent | Good | Fair | Good |

| Sterilization Resistance | Excellent | Limited | Poor | Poor |

| Odor/Taste | None | Slight | Noticeable | None |

| Durability | High | Medium | Low | Medium |

This comparison clearly shows why LSR is the premium choice for medical mask devices.

Regulatory Compliance and Medical Standards

Medical-grade LSR can comply with:

- FDA 21 CFR 177.2600

- ISO 10993 (biological evaluation)

- USP Class VI

- RoHS and REACH

Using compliant LSR materials simplifies regulatory approval for medical device manufacturers entering the US and European markets.

Why Medical Device Manufacturers Prefer LSR

Medical OEMs choose liquid silicone rubber because it:

- Reduces product failure risk

- Improves patient and user comfort

- Supports advanced mask designs

- Ensures consistent quality at scale

For medical mask devices where safety and performance cannot be compromised, LSR is the material of choice.

Conclusion

Choosing the right material is essential for the success of any medical mask device. Liquid Silicone Rubber stands out due to its biocompatibility, comfort, sealing performance, durability, and regulatory compliance.

With advanced LSR injection molding technology, manufacturers can produce high-precision, reliable, and user-friendly medical masks that meet the highest healthcare standards.

For medical device companies aiming to deliver safe, comfortable, and high-performance medical mask solutions, liquid silicone rubber is not just an option—it is the optimal choice.