Table of Contents

ToggleAs pet ownership continues to rise globally, so does the demand for high-quality, safe, and innovative pet products. From chew toys and feeding accessories to wearable pet gear, manufacturers are turning to advanced materials to meet the expectations of pet parents. One material that stands out in this space is Liquid Silicone Rubber (LSR) — a premium, medical-grade silicone known for its exceptional performance, safety, and versatility.

In this article, we explore why LSR is the ideal choice for pet products, highlighting its unique benefits, applications, and impact on product quality and brand competitiveness.

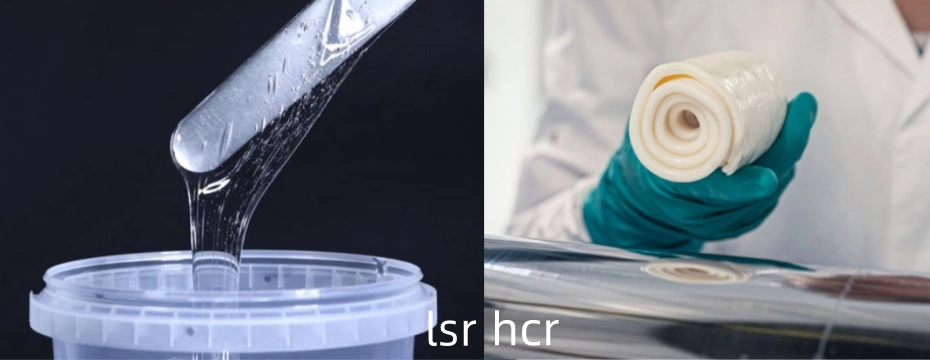

1. What Is Liquid Silicone Rubber (LSR)?

Liquid Silicone Rubber (LSR) is a two-component, platinum-cured elastomer that is injected into molds to form precise, durable, and flexible parts. It differs from traditional silicone in its injection molding process, which allows for higher efficiency and consistency in mass production.

Its physical properties include:

- High flexibility and softness

- Excellent biocompatibility

- Extreme temperature resistance

- UV, water, and chemical resistance

- Odorless and tasteless nature

These characteristics make LSR particularly suitable for pet products where safety, hygiene, and comfort are key priorities.

2. Why Is LSR Ideal for Pet Products?

a. Pet-Safe and Non-Toxic

Safety is paramount in pet accessories and toys, especially those that come into direct contact with a pet’s mouth, skin, or food. LSR is:

- BPA-free, phthalate-free, and lead-free

- FDA and RoHS compliant

- Hypoallergenic and suitable for sensitive pets

This makes it an excellent alternative to rubber, PVC, or low-quality plastic often found in traditional pet items.

b. Soft Yet Durable

Pet toys and chewables need to balance softness for comfort and durability against bites and scratches. LSR offers:

- High tear strength

- Excellent recovery after stretching

- Long-term mechanical stability even under repeated stress

Whether it’s a chew toy for a teething puppy or a flexible food mat, LSR maintains its form and performance over time.

c. Easy to Clean and Hygienic

Hygiene is essential for pet health. LSR is:

- Naturally resistant to bacteria and mold

- Non-porous — meaning it doesn’t trap dirt or odors

- Dishwasher safe and easy to sanitize

This makes it the ideal material for feeding bowls, lick mats, water bottle nipples, and more.

d. Weather and Temperature Resistance

From hot summer walks to cold winter outings, pet products often face diverse environments. LSR resists:

- Temperatures from -50°C to 250°C (-58°F to 482°F)

- UV rays, ozone, and harsh weather conditions

This resilience makes LSR suitable for outdoor pet gear, booties, protective collars, and travel accessories.

e. Superior Design Flexibility

LSR can be molded into intricate, customized shapes with various textures, colors, and durometers. For brands and designers, this means:

- High design freedom for creative, functional pet items

- Easy integration of logos, grip patterns, and safety features

- Compatibility with overmolding on plastic or metal parts

Innovative brands can deliver pet products that stand out both in appearance and function.

3. Common Pet Products Made with Liquid Silicone Rubber

Here are some of the most common pet products where LSR is making a significant impact:

| Product Type | Benefits of LSR Use |

|---|---|

| Chew Toys | Safe to chew, flexible yet strong, non-toxic |

| Feeding Mats & Bowls | Anti-slip, hygienic, easy to clean |

| Water Bottle Nipples | Soft, food-safe, leak-resistant |

| Grooming Tools | Skin-friendly, flexible, chemical-resistant |

| Travel Accessories | Temperature-stable, foldable, lightweight |

| Wearables (Collars, Tags) | Comfortable, weatherproof, customizable |

| Lick Mats & Slow Feeders | Soft texture, promotes slow eating, dishwasher safe |

4. Environmental and Sustainability Considerations

Today’s consumers are increasingly eco-conscious, and brands that use sustainable materials gain a competitive edge. While LSR is not biodegradable, it offers:

- Long lifespan reducing the need for replacements

- Low VOC emissions during manufacturing

- Minimal waste through precise injection molding

Additionally, many manufacturers adopt clean-room processing to ensure a low-environmental-impact production process, especially for medical or baby-grade silicone used in pet care.

5. Cost and ROI Considerations

While LSR may have a higher upfront tooling cost than thermoplastics, its benefits often outweigh the initial investment:

- Lower long-term costs due to product longevity and low returns

- High brand value with premium, safe materials

- Efficient production with fast cycle times

For manufacturers targeting high-end or health-conscious pet owners, LSR products can command a higher retail price and brand loyalty.

6. How to Start Manufacturing Pet Products with LSR

If you’re a product developer or brand interested in using LSR, here are steps to consider:

- Define your product needs: Consider function, durability, user experience.

- Select a trusted LSR molder: Look for experience in medical, baby, or pet-grade products.

- Prototype and test: Use rapid prototyping to ensure fit and performance.

- Finalize design and tooling: Optimize for moldability and cost-efficiency.

- Launch with marketing focused on safety and quality.

7. Case Study: LSR Chew Toys vs. Rubber Toys

Traditional rubber chew toys may degrade, crack, or leach chemicals over time. In contrast, LSR chew toys:

- Maintain elasticity and softness for months or years

- Do not discolor or emit odors

- Are trusted by vets and pet nutritionists

More and more premium pet brands are transitioning to LSR to meet the demands of informed pet parents.

Conclusion

Liquid Silicone Rubber is redefining the standards for pet products by offering unparalleled safety, hygiene, durability, and design flexibility. Whether you’re a pet product startup or an established brand looking to upgrade your offerings, LSR provides a future-proof solution for creating innovative, reliable, and pet-friendly products.

By choosing LSR, you’re not just investing in material — you’re investing in pet wellness, customer trust, and brand excellence.